Wood Framed Aluminum Tin Sheets - Checkered Aluminum Sheet AA1100 for Automotive Body

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Checkered Aluminum Sheet AA1100 for Automotive Body

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Checkered Aluminum Sheet AA1100 for Automotive Body

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Checkered Aluminum Sheet AA1100 for Automotive Body

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

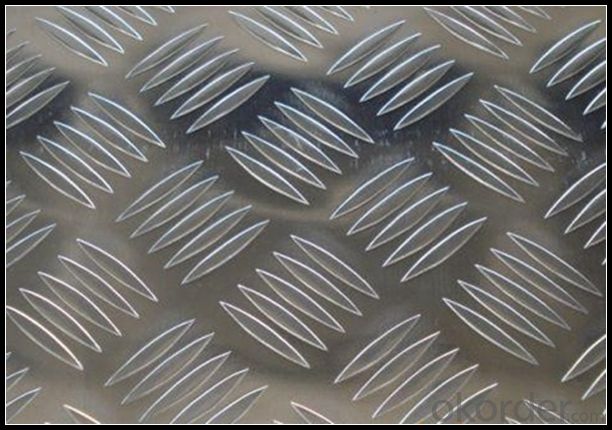

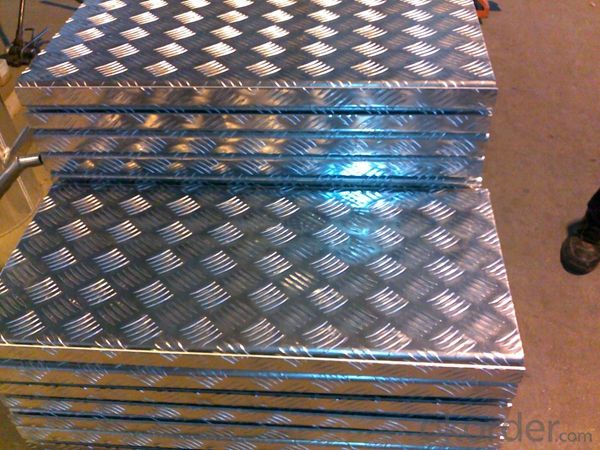

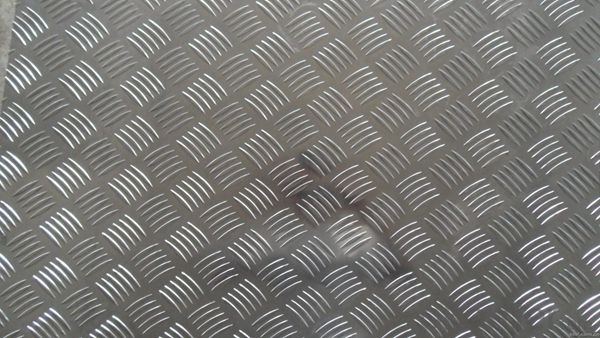

5. Image of Checkered Aluminum Sheet AA1100 for Automotive Body

6. Package and shipping of Checkered Aluminum Sheet AA1100 for Automotive Body

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What can I do to remove the paint from the painted aluminum sheet?

- The aluminum need scraping, the car is not easy to enamel paint.Is the aluminum plate with a thickness of more than 0.2mm to 500mm, 200mm width, length less than 16m aluminum material called aluminum plate or aluminum sheet, aluminum is below 0.2mm, 200mm within the width of the row material or bar (of course, with the progress of the large equipment, the width can be 600mm row material also more).

- Q: How does aluminum sheet perform in high-pressure applications?

- Aluminum sheet performs exceptionally well in high-pressure applications due to its inherent properties. The strength-to-weight ratio of aluminum is impressive, making it a suitable choice for withstanding high-pressure environments. Additionally, aluminum has excellent corrosion resistance, which is crucial when dealing with high-pressure conditions that may involve exposure to moisture or aggressive chemicals. Furthermore, aluminum sheet is highly malleable, allowing it to be fabricated into various shapes and forms to meet the specific requirements of high-pressure applications. Its flexibility also enables it to withstand the forces and stresses exerted during high-pressure processes without compromising its structural integrity. Moreover, aluminum has good thermal conductivity, which aids in dissipating heat generated by high-pressure systems. This feature helps prevent overheating and ensures efficient operation. However, it is important to note that the performance of aluminum sheet in high-pressure applications can be influenced by factors such as the thickness and alloy composition of the sheet. Therefore, it is crucial to select the appropriate grade and thickness of aluminum sheet based on the specific requirements and operating conditions of the high-pressure application. Overall, aluminum sheet is a reliable and effective choice for high-pressure applications due to its strength, corrosion resistance, malleability, thermal conductivity, and overall performance under demanding conditions.

- Q: What are the different methods of forming aluminum sheets?

- There are several methods of forming aluminum sheets, each with its own advantages and applications. Here are some of the different methods: 1. Rolling: Rolling is the most common method used to form aluminum sheets. In this process, a large aluminum ingot is passed through a series of rolling mills, which gradually reduce its thickness and increase its length. The ingot is rolled multiple times until the desired thickness is achieved. Rolling can produce aluminum sheets of various thicknesses and widths, making it versatile for different applications. 2. Extrusion: Extrusion is another method used to form aluminum sheets, especially for complex cross-sectional profiles. In this process, a heated aluminum billet is forced through a shaped die, resulting in a continuous length of aluminum with the desired shape. Extrusion allows for the creation of intricate designs and is often used in the production of structural components and frames. 3. Casting: Casting is a method used to form aluminum sheets with a specific shape or pattern. In this process, molten aluminum is poured into a mold and allowed to cool and solidify. The mold can be made of various materials, such as steel or sand, depending on the complexity of the desired shape. Casting is commonly used for decorative purposes and in the production of architectural panels. 4. Stretch forming: Stretch forming is a specialized method used to form aluminum sheets into curved or contoured shapes. In this process, the sheet is clamped at its edges and stretched over a form, using hydraulic or mechanical forces. As the sheet is stretched, it conforms to the shape of the form, resulting in a curved or contoured sheet. Stretch forming is commonly used in the aerospace and automotive industries for components such as fuselage sections and car body panels. 5. Pressing: Pressing, also known as stamping or punching, is a method used to form aluminum sheets into specific shapes or patterns. In this process, the sheet is placed between a die and a punch, and pressure is applied to deform the sheet. The die and punch can have various designs and can create shapes ranging from simple cutouts to intricate patterns. Pressing is commonly used in the manufacturing of automotive parts, appliances, and electronic enclosures. These are just a few of the different methods of forming aluminum sheets. Each method offers unique advantages and is chosen based on the specific requirements of the desired shape, thickness, and application of the aluminum sheet.

- Q: Are the aluminum sheets suitable for manufacturing electrical enclosures?

- Yes, aluminum sheets are suitable for manufacturing electrical enclosures. Aluminum is a lightweight, durable, and corrosion-resistant material, making it an excellent choice for enclosures that require electrical conductivity and protection. Additionally, aluminum can be easily manipulated and formed into various shapes, allowing for customization and efficient manufacturing processes.

- Q: Are 101 aluminum sheets suitable for chemical transfer piping?

- No, 101 aluminum sheets are not suitable for chemical transfer piping as they are not corrosion resistant and may react with certain chemicals, leading to potential leaks or contamination.

- Q: Can aluminum sheets be anodized with custom colors?

- Custom colors can indeed be applied to aluminum sheets through the process of anodizing. Anodizing involves the application of an electrochemical procedure that adds a protective oxide layer to the aluminum's surface, thereby enhancing its durability and resistance to corrosion. In this process, the aluminum sheet is submerged in an electrolytic solution while an electrical current is passed through it. This induces a controlled oxidation of the aluminum's surface, leading to the formation of a porous layer that can be colored with dyes to achieve desired shades and hues. By carefully selecting the appropriate dye, a wide array of custom color options can be achieved. Moreover, anodized aluminum sheets offer versatility as they can undergo additional treatments like laser engraving or printing to create distinctive designs and patterns. Therefore, they are highly suitable for a diverse range of applications in industries such as architecture, automotive, and electronics.

- Q: Can aluminum sheets be used in marine environments?

- Yes, aluminum sheets can be used in marine environments. Aluminum is a commonly used material in marine applications due to its excellent corrosion resistance. It forms a protective oxide layer on its surface, which prevents further corrosion in the presence of saltwater or other corrosive elements found in marine environments. Aluminum sheets are lightweight, yet strong, making them ideal for a variety of marine structures such as boat hulls, decks, and superstructures. Additionally, aluminum is highly durable and has a long lifespan, further enhancing its suitability for marine applications.

- Q: Can aluminum sheet be used for electrical wiring?

- No, aluminum sheet cannot be used for electrical wiring.

- Q: Are the aluminum sheets corrosion-resistant?

- Indeed, aluminum sheets exhibit resistance to corrosion. When aluminum is exposed to oxygen, a protective oxide layer naturally develops, effectively inhibiting corrosion. This oxide layer acts as a shield, separating the aluminum from its surroundings and granting the sheets exceptional resistance against corrosion. Moreover, aluminum sheets can undergo additional treatments such as coatings or anodizing processes, further amplifying their resistance to corrosion. Consequently, aluminum sheets are widely favored for applications where the necessity for corrosion resistance is paramount.

- Q: There are about 200 holes on the aluminum plate to be machined. There are 100 M12 thread holes, and the rest are 15MM through holes. The tolerance is +0.02. Seeking detailed processing technology, is the first hole or first processing plane, how to control the amount of deformation of the plate, if the milling process can not guarantee flatness, on the grinder, then the 2 surfaces to stay 2MM margin? Are there any 15MM through holes that can be used to maintain tolerances, or do they need to be boring?. Great God advice, the best detail. Aluminum so much done before, no experience, if it does it scrapped.

- Brother, I want to tell you first, the aluminum grinding machine is very rare! Because the aluminum sticky grinding wheel!No money, people are: 1., flying base level, thickness to 26.5 low point! 2. turn the face, press 4 sides, drill rough. The 3. lock bolt is in the hole you hit! Notice here that the lock must be locked one by one! Do you think the workpiece completely tied to lock dead in the fixture, and then processing the thickness to 25.6, the Kong Xian crude drilling reamer locking bolt end processing in place, lock 4. replacement bolts, the original lock bolt hole processing in place! 5., the final flying surface, according to each side of the 0.3 to fly surface, flying surface fixed method, you can use hot melt adhesive or hard rubber mud to fix the workpiece 4 sides and forming the inner hole!The rich person is the vacuum sucker, the base level as much as 26.5, turn over the surface of the vacuum sucker, forming directly!Hope to adopt, typing hard enough!

Send your message to us

Wood Framed Aluminum Tin Sheets - Checkered Aluminum Sheet AA1100 for Automotive Body

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords