Aluminum Brazing Sheets - Alloy 1100 Aluminum Sheet for Circuit Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

Alloy 1100 Flat Aluminum Sheet for Circuit Board

l Product Introduction

1.Superior quality of raw material.

2.Reasonable and stable chemical composition.

3.Accurate tolerance.

4.Goode mechanical property.

5.We have the certificate of ISO9001.

l Product Description

| PS Board Base | ||

| Alloy: | 1060 | |

| Temper: | H18 | |

| Thickness: | 0.14mm~0.27mm | |

| Width: | 300--1250mm | |

| Tensile Strength: | ≥140Mpa | |

| Elongation: | ≥2.0% | |

| Circuit/Lighting sheet | ||

| Alloy: | 1060/1100/8011/1050 | |

| Temper: | H16/H18 | |

| Thickness: | 0.14mm~0.50mm | |

| Width: | 300--1250mm | |

| Tensile Strength: | 165~195Mpa | |

l Packaging & Delivery

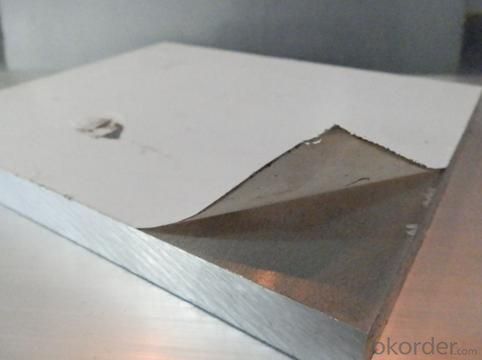

Packaging detail: Seaworthy Export Standard Wooden Pallet and with damp proof film as first layer, Kraft paper as second layer, Cardboard card as third layer Criss-cross steel strip to fix outside

Delivery detail: About 25 days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

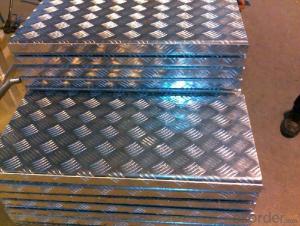

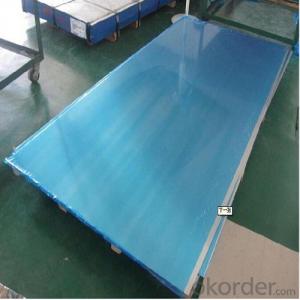

l Products Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: What is the cost of aluminum sheets compared to other metals?

- The cost of aluminum sheets can vary in comparison to other metals, depending on various factors like grade, thickness, size, and market conditions. However, in general, aluminum sheets are typically more cost-effective than other metals. This is because aluminum is one of the most abundant elements on Earth, making it more easily accessible and less costly to produce. Furthermore, aluminum has a lower density than many other metals, meaning that less material is required to achieve the same level of strength and durability. This contributes further to its lower cost. On the other hand, metals such as steel or titanium may be pricier due to their scarcity or higher processing expenses. Nevertheless, it's important to note that prices can fluctuate over time due to various economic factors. Therefore, it is always advisable to check the current market prices before making any purchasing decisions.

- Q: What is the lifespan of aluminum sheets?

- The lifespan of aluminum sheets can vary depending on various factors such as their usage, environment, and maintenance. However, when properly cared for, aluminum sheets can last for decades or even a lifetime due to their inherent resistance to corrosion and durability.

- Q: What the glue of L solidified aluminum and fast acrylic plate, solid glue?

- Aluminum and acrylic adhesive, if you want to achieve high strength without any effect, can be bonded with KD-5603 trace glue, but this should be with the help of UV curing light curing, if there is no UV curing light, the sun is strong weather, stick in the sun after 30 minutes can be the bonding effect of glass panel; the specific effects can refer to the general glass coffee table with four Aluminum Alloy column, don't see any traces of adhesive;If you only need sticky sticks and low marks, you can choose N-906AB glue or KD-855 quick drying metal glue

- Q: Are 101 aluminum sheets suitable for chemical storage tanks?

- No, 101 aluminum sheets are not suitable for chemical storage tanks. Aluminum, especially 101 aluminum, is not resistant to many chemicals and can react with them, leading to corrosion and potential leakage. Chemical storage tanks require materials that are specifically designed to withstand the corrosive nature of chemicals, such as stainless steel or certain types of plastics. It is essential to use materials that are chemically resistant and can ensure the safety and integrity of the stored chemicals.

- Q: What are the semi hard ones? What are the alloys? What are the anti rust ones, such as 3003505210606061, 7075?

- 3003: board. Strip foil. Tensile plate, tube. Extrusion tube. Type. Rod. Rod. Cold bar, cold wire, rivet wire, forging, foil, heat sink material mainly used for processing requires good molding property, high corrosion resistance, good weldability and spare parts not only have these requirements, or performance need than the workpiece of 1*** alloy with high strength, such as transportation of liquid tank and tank, pressure tank, storage device, heat exchanger, chemical equipment, aircraft fuel tank, oil pipe, reflective panels, kitchen equipment, cylinder washing machine, rivet, welding wire.3003 aluminum alloy sheet, plate, tube drawing. The extruded tube housing partition, cap, pipe3004 plate, plate, pipe extrusion tube for tensile. As long as the whole aluminum cans cans, for more than 3003 alloy parts, chemical products production and storage device, sheet processing, building baffle, cable conduit, sewer, various lighting components.3004 aluminum alloy sheet, plate mainly used for housing partition, baffle, sewer, the roof of industrial plant5052 plate, plate, sheet, foil, drawing tube, cold processing bar, cold wire, rivet wire, this alloy has good shaping property, high corrosion resistance, weldability and fatigue strength, medium static strength, used in the manufacture of aircraft fuel tank, tubing, and vehicles, sheet metal parts, ship the instrument, street lamp and rivet wire and so on.

- Q: What are the different methods of cutting aluminum sheets?

- There are several methods of cutting aluminum sheets, including shearing, sawing, laser cutting, waterjet cutting, and CNC milling. Each method has its advantages and suitability depending on the thickness and complexity of the aluminum sheet, as well as the desired precision and speed of the cut.

- Q: This question asks about the effects of using aluminum sheets in the construction industry on the environment.

- <p>The environmental impacts of using aluminum sheets in construction are multifaceted. On the positive side, aluminum is lightweight, which reduces energy consumption during transportation. It is also recyclable, with a high percentage of construction aluminum being recycled, reducing waste. However, the production of aluminum is energy-intensive, contributing to greenhouse gas emissions. Additionally, mining for bauxite, the primary source of aluminum, can lead to habitat destruction and water pollution. Despite these concerns, aluminum's durability and resistance to corrosion can extend the lifespan of buildings, reducing the need for frequent replacements and thus the overall environmental footprint over time.</p>

- Q: If you're familiar with some of my previous questions, you'll know I have a thing for DC-3's, and I'd like to buy one and fix it up at some point in my life. I was looking at pictures on Google for my desktop background and saw several with shiny chrome/aluminum bodies. Well, first of all, is it chrome or polished aluminum? Second, would I be able to buy a DC-3 painted this God-awful forest green and put whatever it is (chrome/aluminum) on said plane? Or is it something that the plane has to be built with originally?

- The polished aluminum that DC3's carried (actually any airplane) is the unfinished aluminum that they were built with. It takes lots and lots of work to remove old paint and then polish to get the shine you want. You can not chrome the aircraft, It has to be polished then kept polished and that isn't easy. PS - a repaint is much easier and protects the raw materials much better. However, I agree that a polished aluminum aircraft is very pretty.

- Q: This question asks for a comparison of the positive and negative aspects of utilizing aluminum sheets in building construction.

- <p>Aluminum sheets in construction offer several advantages, including lightweight properties that reduce structural load, excellent corrosion resistance, and durability which minimizes maintenance needs. They are also energy-efficient, reflecting heat and reducing cooling costs. Additionally, aluminum is recyclable, contributing to sustainability. Disadvantages include higher initial costs compared to some traditional materials and potential for dents or damage from impacts. Aluminum can also be noisy when walked on, and it may require additional insulation for thermal performance, adding to the overall cost.</p>

- Q: Are the aluminum sheets suitable for manufacturing architectural column covers?

- Yes, architectural column covers can be manufactured using aluminum sheets. Aluminum is a material that is both lightweight and durable, offering excellent resistance to corrosion. This makes it an ideal choice for exterior applications like column covers. It is also easily shaped, bent, and fabricated, allowing for the creation of customized designs and sizes. This versatility is beneficial for architectural projects. Furthermore, aluminum sheets can be finished with various coatings, such as powder coating or anodizing, to enhance their visual appeal and provide extra protection against weathering and wear. Overall, aluminum sheets are a suitable option for manufacturing architectural column covers due to their combination of strength, versatility, and aesthetics.

Send your message to us

Aluminum Brazing Sheets - Alloy 1100 Aluminum Sheet for Circuit Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords