Aluminum Sheets Kentucky - 1100-H14 Aluminium Sheet and Plates

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

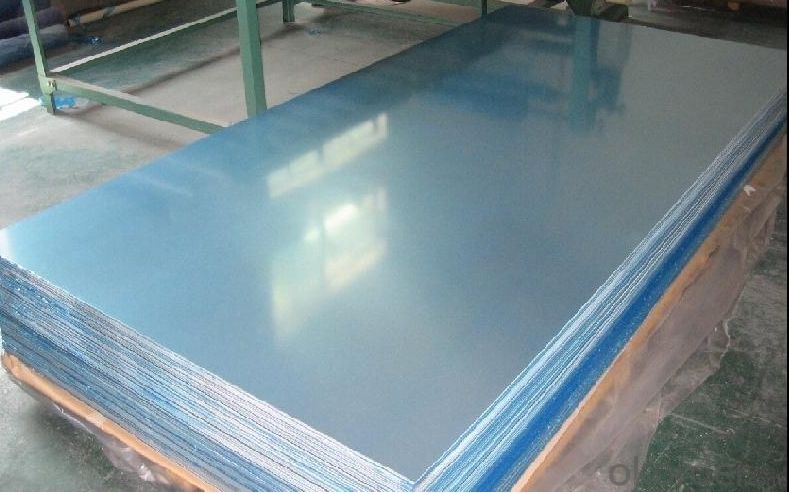

1.Structure of Product Description

Our aluminium sheet can be including cold rolled and hot rolled, etc.

They are widely used in different fields, such as: construction, decoration, etc. The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

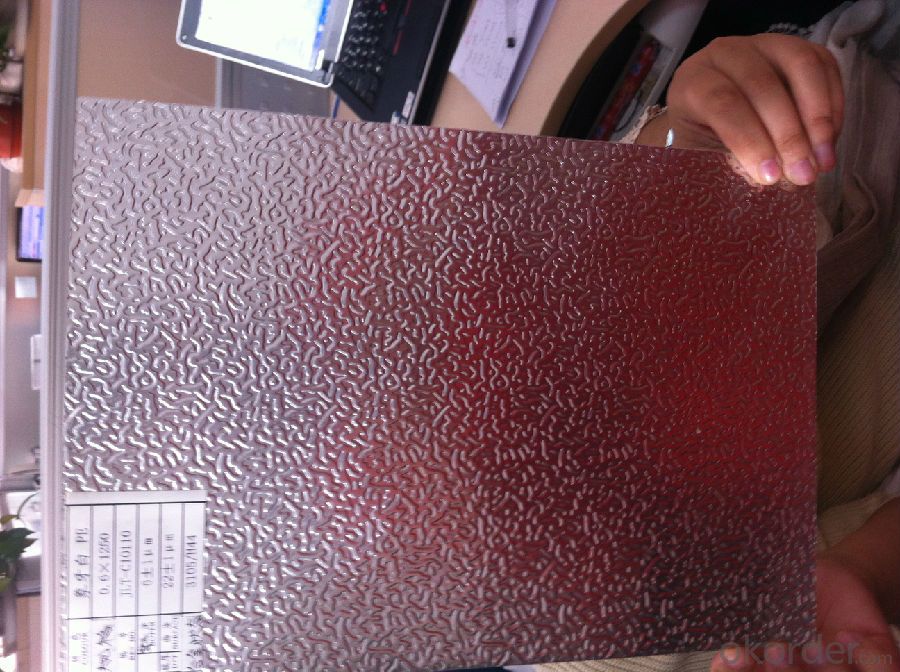

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 600mm to 2500mm, etc.

how many tons will be export in one yar?

---it is around 9000 tons in one year.

what is your mainly products?

---normally our mainly products are as follows:

aluminum sheet, aluminum coil, aluminium chekcered sheet, mirror finish sheet, etc.it is very best-selling recently, based on our best-competitiveprice, etc.

- Q: What are the different methods of surface patterning aluminum sheets?

- Aluminum sheets can be patterned using a variety of methods, each with its own benefits and applications. Some commonly used techniques include: 1. Mechanical Etching: By employing abrasive materials like sandpaper or wire brushes, patterns can be created on the aluminum surface. Different pressures and movements can be applied to achieve desired designs. Mechanical etching is a versatile and cost-effective method suitable for both simple and complex patterns. 2. Chemical Etching: Also known as chemical milling, this method involves using chemicals to selectively remove material from the aluminum surface and form patterns. The aluminum sheet is coated with a resist and then submerged in an etchant solution, which dissolves the exposed areas, leaving behind the desired pattern. Chemical etching allows for precise and intricate designs but requires careful control of the etching process. 3. Laser Engraving: This technique utilizes a high-power laser beam to remove material from the aluminum surface and create patterns. The laser beam is controlled by computer software, enabling precise and detailed designs. Laser engraving is suitable for both small and large-scale production, offering high accuracy and repeatability. 4. Embossing: In this method, the aluminum sheet is pressed between two dies with raised patterns, resulting in a three-dimensional design on the surface. Embossing can be achieved through mechanical or hydraulic presses and is commonly used to add texture and aesthetic appeal to aluminum sheets, such as for decorative purposes or branding. 5. Printing: Various printing techniques can be employed to apply patterns onto aluminum sheets. These include screen printing, which involves forcing ink through a mesh screen onto the aluminum surface, and digital printing, which utilizes inkjet technology for high-resolution patterns. Printing methods allow for a wide range of colors and designs, making them suitable for decorative applications. The choice of surface patterning method depends on factors such as desired pattern complexity, production volume, cost considerations, and the intended end-use of the aluminum sheets. Each method offers distinct advantages and limitations, allowing manufacturers to select the most suitable technique according to their specific requirements.

- Q: A 15.1 g aluminum block is warmed to 53.2 °C and plunged into an insulated beakercontaining 32.6 g of water initially at 24.4 °C. The aluminum and the water are allowed to cometo thermal equilibrium.Assuming that no heat is lost, what is the final temperature of the water and aluminum?

- To solve this problem, you need the heat capacity of water and Al, I know off hand the heat capacity of water but you'll need to look it up for Al. From the problem, you know that the heat given up as the aluminum cools is gained by the water heating up. As there is no phase change, the heat gained (or lost) is mass * heat capacity * temperature change energy gained by water = energy lost by Al. Let Tf be the final temperature of the Al and water. 32.6 g * 4.18 J/gK * (Tf - 24.4C) = 15.1 g * heat capacity of Al * (53.2 C - Tf) Solve for Tf. Because there is almost twice as much water as Al and water has a higher heat capacity than Al, the temperature will be closer to 24.4C than it is to 53.2C

- Q: The only materials i can use is iodine, water, HCl, magnet, and pH paper. How do you identify aluminum with that?

- To start with, are you refering to aluminum as metal, an aluminum compound, or a solution with aluminum present as ions? If it is metaallic aluminum, it won't stick to a magnet, and it will react with HCl, however this isn't sufficient to definately say it is aluminum, it would be better to get a density, melting point, etc.

- Q: im making a presentation and once i read through it it feels like its leading up to something but then goes flat. any ideas. my project ' steel cars compared to aluminium'

- Aluminium is extremely flammable. We use it in thermite welding and as solid rocket fuel. The Emperor Napoleon carried* an aluminium fork while the lower royalty had to make do with gold forks. *In those days people carried their table wear around with them same as we carry our car keys.

- Q: What characteristics distinguish aluminum sheets from other types of sheets?

- <p>Aluminum sheets are lightweight, corrosion-resistant, and have excellent thermal and electrical conductivity. They are commonly used in construction, automotive, and packaging industries. In contrast, other types of sheets, such as steel sheets, are heavier and stronger but less resistant to corrosion. Plastic sheets are lightweight and flexible but have lower strength and thermal conductivity. Copper sheets offer high thermal and electrical conductivity but are more expensive and less resistant to corrosion than aluminum. Each type of sheet has unique properties that make it suitable for specific applications.</p>

- Q: I need help with this question for a report i'm doing, it's about recycling aluminium, please could you give me some reasons why to recycle aluminium and eg.saves energy, and how it does eg. saves energy by...Thanks a lot this will help me loads.P.S this is just a report for my science project.

- This Site Might Help You. RE: Why should we recycle aluminium? I need help with this question for a report i'm doing, it's about recycling aluminium, please could you give me some reasons why to recycle aluminium and eg.saves energy, and how it does eg. saves energy by... Thanks a lot this will help me loads. P.S this is just a report for my science project.

- Q: Are aluminum sheets suitable for automotive body panels?

- Yes, aluminum sheets are suitable for automotive body panels for several reasons. Firstly, aluminum is a lightweight material, which helps improve fuel efficiency and overall vehicle performance. This can result in better acceleration, handling, and braking. Additionally, the use of aluminum body panels can contribute to reducing the overall weight of the vehicle, which is particularly important for electric vehicles, as it can extend their range. Secondly, aluminum has excellent corrosion resistance properties. It naturally forms a protective oxide layer on its surface, which helps prevent rusting and deterioration caused by exposure to various weather conditions. This makes aluminum sheets highly durable and long-lasting, ensuring that automotive body panels maintain their structural integrity over time. Furthermore, aluminum is highly malleable and can be easily formed into complex shapes using various manufacturing techniques such as stamping, extrusion, and hydroforming. This allows for greater design flexibility, enabling automakers to create vehicles with sleek and aerodynamic body styles. Additionally, aluminum can be easily joined through welding or adhesive bonding, making it easier to assemble and repair automotive body panels. Moreover, aluminum is a sustainable material as it is highly recyclable. Recycling aluminum requires significantly less energy compared to primary production, resulting in reduced greenhouse gas emissions. This aligns with the growing emphasis on sustainability and environmental consciousness in the automotive industry. Overall, the use of aluminum sheets in automotive body panels offers numerous advantages such as improved fuel efficiency, corrosion resistance, design flexibility, and sustainability. These factors make aluminum a suitable and increasingly popular choice for automakers aiming to enhance the performance, durability, and environmental friendliness of their vehicles.

- Q: Aluminum plate thickness 3 mm, what is the allowable error in the national standard thickness?

- Length: + 1mmWidth: + 0.5mmThickness: + 0.02mm, that is, 2 filaments

- Q: What are the different methods of surface texturing aluminum sheets?

- There are several methods of surface texturing aluminum sheets, each with its unique advantages and applications. 1. Mechanical Texturing: This method involves the use of mechanical tools or processes to create patterns or textures on the surface of aluminum sheets. Examples include brushing, sanding, or embossing. Mechanical texturing is commonly used to create a matte or brushed finish on aluminum sheets, which enhances their aesthetic appeal and hides surface imperfections. 2. Chemical Texturing: Chemical texturing involves the use of chemicals to etch the surface of aluminum sheets and create unique patterns or textures. Acid etching is a common chemical texturing method that involves immersing the aluminum sheet in an acid solution to selectively dissolve the surface and create a textured surface. Chemical texturing is often used to improve the adhesive properties of aluminum sheets, making them suitable for bonding or coating applications. 3. Anodizing: Anodizing is an electrochemical process that creates a controlled oxide layer on the surface of aluminum sheets. This process can be used to create a variety of surface textures, ranging from a smooth, glossy finish to a rough, matte finish. Anodizing not only provides a textured appearance but also enhances the corrosion resistance and durability of the aluminum sheet. It is commonly used in architectural applications, consumer products, and automotive parts. 4. Laser Texturing: Laser texturing involves the use of laser technology to create precise and intricate patterns or textures on the surface of aluminum sheets. Laser beams can be precisely controlled to remove material or modify the surface in a desired pattern, allowing for highly customizable and detailed textures. Laser texturing is often used in decorative or high-end applications, such as jewelry, signage, or interior design. Each method of surface texturing aluminum sheets offers unique benefits and is suitable for different applications. The choice of texturing method depends on factors such as the desired texture, durability requirements, aesthetic preferences, and intended use of the aluminum sheets.

- Q: Aluminum siding is essentially maintenence-free, extremelydurable, and is a great insulator, even better than brick. Brickleaks air through the mortar between the bricks, especially in olderhouses that need tuckpointing. My question is, do you feel sidingstill has a declasse connotation, or is it getting more acceptableas the years go on?

- No worse than vinyl. The advantage vinyl has over aluminum is its resistance to denting. Siding is a good finish, but if you've already got a brick exterior, you're wasting the hard hours the masons put in to make it. If the brick has deteriorated or is horribly scarred, like having survived a hurricane or tornado, then sure, siding will spiff it up cosmetically as well as adding insulation value. That said, I'd rather take a house with aluminum siding over wood any day...and vinyl over that. If you get the siding in the color you want, as it's the entire thickness of the vinyl, powerwashing the outside won't take the color off as it could with painted wood or (though less likely) the finish on the aluminum...unless you *like* painting :)

Send your message to us

Aluminum Sheets Kentucky - 1100-H14 Aluminium Sheet and Plates

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords