Aluminum Sheets for Trailer Siding - Color Coated Aluminium Sheet for Building Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coated Aluminium Sheet for Building Curtain Wall

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

PAINT THICKNESS | Top:18--25um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

2. Application of Color Coated Aluminium Sheet for Building Curtain Wall

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coated Aluminium Sheet for Building Curtain Wall

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

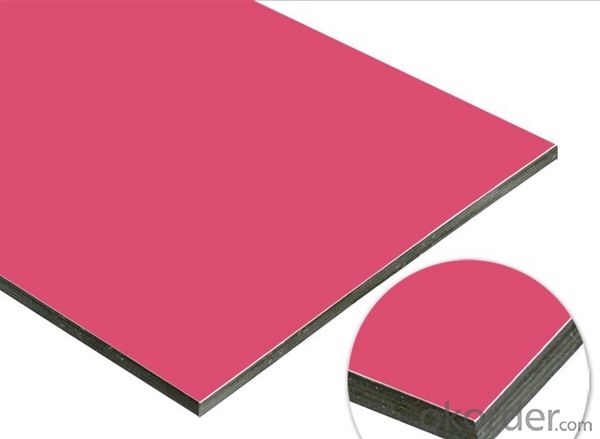

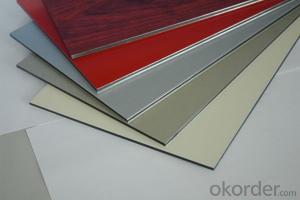

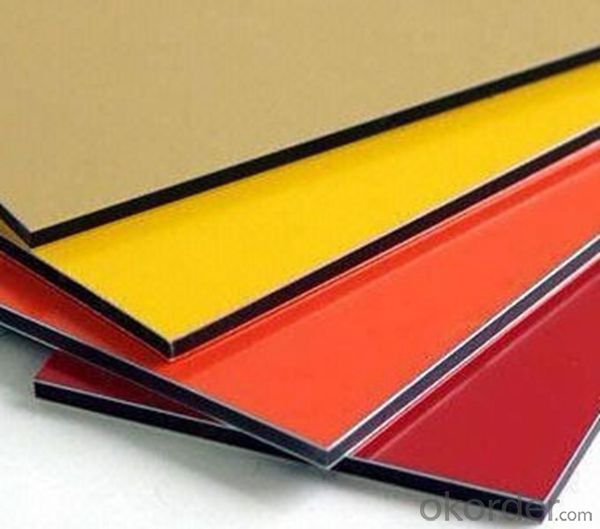

5. Image of Color Coated Aluminium Sheet for Building Curtain Wall

6. Package and shipping of Color Coated Aluminium Sheet for Building Curtain Wall

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is the most effective technique for applying a coating to aluminum sheets?

- <p>The best method for coating aluminum sheets depends on the desired application and properties of the coating. Common methods include anodizing, which provides a protective oxide layer, powder coating for a durable finish, and electroplating for enhanced corrosion resistance. For decorative purposes, methods like painting or vacuum deposition can be used. Each method has its advantages and is chosen based on factors such as cost, durability, and aesthetic requirements.</p>

- Q: Can aluminum sheets be used for curtain walls?

- Yes, aluminum sheets can be used for curtain walls. Aluminum is a popular choice for curtain wall systems due to its lightweight nature, durability, and corrosion resistance. Aluminum sheets can be easily formed into various shapes and sizes, making them suitable for creating the structural frame of curtain walls. Additionally, aluminum can be coated or anodized to enhance its aesthetic appeal and provide additional protection against weather elements. This makes aluminum sheets a versatile and practical material for constructing curtain walls in commercial and residential buildings.

- Q: This question asks for a comparison of aluminum sheets with other common materials used in building insulation, focusing on their properties and performance.

- <p>Aluminum sheets are lightweight and have excellent thermal conductivity, which can be both an advantage and a disadvantage in insulation. They reflect heat well, making them useful in radiant barrier applications, but they are poor insulators as they do not trap heat. In contrast, materials like fiberglass, cellulose, and mineral wool have lower thermal conductivity and are more effective at reducing heat transfer. These materials are better at insulating as they trap air, which is a poor conductor of heat. Foam insulation, such as polyurethane and polystyrene, also offers good thermal resistance due to their closed-cell structure. Overall, aluminum sheets are not typically used as primary insulation but can be effective in specific applications where heat reflection is desired.</p>

- Q: How do I prevent corrosion on aluminum sheets?

- To prevent corrosion on aluminum sheets, there are a few steps you can take: 1. Clean the aluminum sheets regularly: Use a mild detergent or aluminum cleaner to remove any dirt, grime, or chemical residues that may be present on the surface. This will prevent the buildup of corrosive substances. 2. Apply a protective coating: Consider applying a protective coating on the aluminum sheets. There are various types of coatings available, such as clear coats, anodizing, or painting. These coatings act as a barrier between the aluminum and the surrounding environment, preventing corrosion. 3. Avoid contact with corrosive substances: Aluminum can be susceptible to corrosion when it comes into contact with certain chemicals, such as acids, alkalis, or saltwater. Be mindful of the environment in which the aluminum sheets are stored or used and avoid exposure to these corrosive substances. 4. Use proper storage methods: Store aluminum sheets in a dry environment with low humidity levels. Moisture can accelerate the corrosion process, so it's important to keep the sheets dry and protected from excessive moisture. 5. Implement preventive measures: Consider using corrosion inhibitors or anti-corrosion sprays specifically designed for aluminum. These products can provide an extra layer of protection against corrosion, especially in harsh or corrosive environments. By following these preventive measures, you can significantly reduce the risk of corrosion on aluminum sheets and prolong their lifespan.

- Q: What is the typical yield strength of aluminum sheets?

- The typical yield strength of aluminum sheets can vary depending on the grade and thickness of the sheet. However, on average, aluminum sheets have a yield strength ranging from 30 to 100 MPa (megapascals). It is important to note that this is a general range, and specific aluminum alloys may have higher or lower yield strengths. Additionally, the yield strength can also be influenced by factors such as heat treatment and processing conditions.

- Q: How do aluminum sheets perform in terms of chemical resistance?

- Good chemical resistance properties are typically found in aluminum sheets. However, their performance may vary depending on the specific chemical environment and conditions. Aluminum is known for its excellent resistance to corrosion from most acids, alkalis, and organic solvents. It creates a protective oxide layer on its surface, preventing further reaction with numerous chemicals. Nevertheless, aluminum can corrode in certain aggressive environments, such as strong acids like hydrochloric acid or sulfuric acid, as well as alkaline solutions with high pH levels. In these instances, the protective oxide layer can deteriorate, leading to the degradation of the aluminum surface. Furthermore, localized corrosion or pitting can occur on aluminum surfaces when exposed to certain chemicals like mercury and specific salts. Therefore, it is important to consider the specific chemicals and concentrations to which the aluminum sheets will be exposed when evaluating their chemical resistance. Various surface treatments, coatings, or alloys can be applied to enhance the chemical resistance of aluminum sheets. These modifications offer additional protection against specific chemicals or environmental conditions, further improving the overall chemical resistance properties of aluminum sheets. In conclusion, aluminum sheets generally possess good chemical resistance. However, their performance can be influenced by the specific chemical environment and conditions. It is advisable to assess the compatibility of aluminum with the intended chemicals and consider appropriate surface treatments or coatings if necessary.

- Q: Can aluminum sheets be anodized with custom designs?

- Yes, aluminum sheets can be anodized with custom designs. Anodizing is an electrochemical process that enhances the natural oxide layer on the surface of aluminum, making it more durable and corrosion-resistant. During this process, different patterns and designs can be added to the aluminum sheet by masking off certain areas and exposing others to the anodizing solution. This allows for custom designs to be etched or dyed onto the surface, creating unique and personalized finishes. Anodized aluminum sheets with custom designs are commonly used in various industries, including architecture, automotive, and electronics, to achieve aesthetic and functional requirements.

- Q: I'd like to have the aluminum on the etching front white. Do any of the experts know that?

- After anodizing, it turns white. If not, the aluminum plate should be white and spray polyester or fluorocarbon paint,

- Q: I just built a stone wall with illuminated glass features embedded, and to make them shine evenly, I had all sides but the visual one wrapped in industrial thickness aluminium foil. One week later, the foil has disintegrated. I have used type 10 Portland. What is going on?

- I believe your problem is that concrete acts as a fairly strong base (this is especially true of mortar mixes). It is well known that strong base will react with an active metal like aluminium and produce hydrogen gas as a byproduct. The representative reaction is: 2Al+6NaOH==2Na3AlO3+3H2, This reaction is fairly rapid and can even cause an explosive buildup of hydrogen gas in a non-ventillated area.

- Q: I was quoted $5000+ to upgrade my house from 100A electric service to 400A. Part of the reason for the high cost is the cost of copper. What size copper wire is needed for 400A, and how much does it cost per foot? Would it be a lot cheaper to use aluminum wire?

- They can be joined but only through a suitable device marked specifically for aluminum to copper connections. See website below.

Send your message to us

Aluminum Sheets for Trailer Siding - Color Coated Aluminium Sheet for Building Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords