Aluminum PVDF Coated Composite Panels - Good Quality and Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

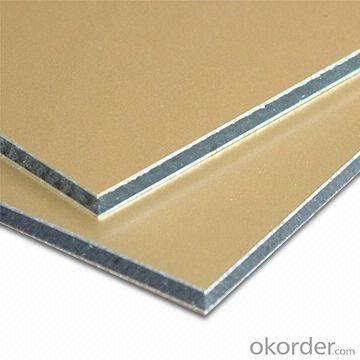

Structure of Aluminium Composite Panels PVDF Description:

PVDF coating aluminium composite panel is composed of a polyethylene core and two aluminium skins. The superb properties of this material boost one’s inspiration and offer architecture a whole new range of solutions, whether your project is a private home, a public building, a corporate headquarter or an office, a trading or industrial complex, or if your organisation wants to create a new image, building Corporate Design, whether for petrol stations, car showrooms, banks or supermarkets.

Main Features of Aluminium Composite Panels PVDF:

A) Light weight,flat surface and high strength

B) Excellent heat insulation ,sound insulation,fire-resistance,acid-resistance,alkali-resistance,weatherproofness and non-resonance

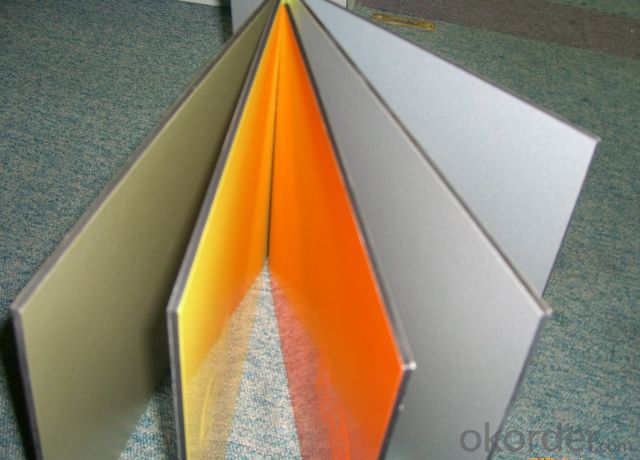

C) Various uniform colors

D) Rbright ,elegan and magnificent,fit for various designs

E) Kynar 5000 PVDF resin feature strong chemical resistance,unique colors can be easily maintained

Images of Aluminium Composite Panels PVDF:

Aluminium Composite Panels Specifications:

Alloy | A1100,A3003,A1050,A8011,A3105,A5005 etc |

Thickness | 0.022mm to 3.0 mm |

Width | Standard width:1240mm; 1200mm |

All width: 30mm - 1600mm | |

Diameter | out dia:1200mm |

Interior dia: 405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE,PVDF,ACRYLIC |

Surface | Embossed, mill finish, coated; aluminum gutter coil |

Color | AS to all RAL color |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ of Aluminium Composite Panels

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 20000㎡.

b. Now which countries do you export your goods?

----Now we export to South East Asia,Africa, North America,South America ect.

- Q: What is the advantage of the aluminum mine in the Yangtze River than other aluminum products?

- What are the advantages of Mengniu and Yili? Brands are pretty much the same!

- Q: What are the pros and cons of utilizing aluminum foil in everyday life?

- <p>Aluminum foil has several advantages, including its affordability, heat conductivity, and ease of use. It's commonly used for food storage, cooking, and insulation. However, it also has disadvantages such as being a single-use item contributing to waste, potential health risks when used with acidic or salty foods, and the environmental impact of its production and disposal. It's lightweight and can be easily torn, which might lead to improper sealing or covering.</p>

- Q: This question asks for a list of typical alloys that are used in the manufacturing process of aluminum.

- <p>Common alloys used in aluminum production include 1000 series (99% pure aluminum), 2000 series (aluminum-copper), 3000 series (aluminum-manganese), 4000 series (aluminum-silicon), 5000 series (aluminum-magnesium), 6000 series (aluminum-magnesium-silicone), and 7000 series (aluminum-zinc). These alloys are chosen for their specific properties, such as strength, corrosion resistance, and workability, which make them suitable for various applications like aerospace, automotive, construction, and consumer goods.</p>

- Q: This question asks for an explanation of the steps involved in producing aluminum.

- <p>The production process of aluminum primarily involves two stages: extraction from bauxite and refining. Initially, bauxite ore, the primary source of aluminum, is mined and then processed to remove impurities. The refined bauxite is then mixed with a hot caustic soda solution in a process called the Bayer Process, which extracts aluminum oxide (alumina). In the second stage, alumina is dissolved in molten cryolite and subjected to an electrolytic reduction process in a Hall-H茅roult cell. This involves passing an electric current through the molten mixture, causing the aluminum oxide to decompose and release pure aluminum, which collects at the bottom of the cell. The aluminum is then tapped off, cooled, and cast into various forms for further processing or use.</p>

- Q: Is it possible to use aluminum as a fuel source?

- <p>Aluminum can be used as a fuel in certain applications, particularly in the form of aluminum powder. It has a high energy density and burns at high temperatures, making it suitable for solid rocket propellants and thermite reactions. However, it is not commonly used as a traditional fuel like gasoline or coal due to its reactivity and the challenges in handling and storage. Aluminum combustion also produces aluminum oxide, which can be harmful to the environment if not managed properly.</p>

- Q: This question asks about the methods and steps involved in processing aluminum.

- <p>Aluminum processing involves several key steps: extraction from bauxite ore, refining, and fabrication. Initially, bauxite is mined and then processed to remove impurities. The Bayer process is commonly used to extract alumina (aluminum oxide) from bauxite by dissolving it in a caustic soda solution. The alumina is then smelted in a reduction furnace using the Hall-H茅roult process, where it is dissolved in molten cryolite and electrolyzed to produce pure aluminum. Finally, the aluminum is shaped and fabricated into various products through methods such as casting, extrusion, or rolling.</p>

- Q: Is it possible to develop allergies from exposure to aluminum found in food packaging materials?

- <p>While aluminum is commonly used in food packaging materials, the risk of allergic reactions to aluminum is generally low for most people. Aluminum is not a known allergen, and exposure through packaging is typically minimal. However, individuals with a rare condition called contact dermatitis may experience skin irritation from aluminum. For the general population, the risk of allergic reactions due to aluminum in food packaging is negligible. It's always important to monitor any unusual reactions and consult a healthcare professional if concerned.</p>

- Q: This question asks for innovative applications of recycled aluminum in various industries or everyday life.

- <p>Recycled aluminum is finding new uses in various sectors due to its sustainability and strength. It's being used in the automotive industry to make lighter vehicles, reducing fuel consumption and emissions. In construction, it's used for building materials like window frames and roofing, known for durability and energy efficiency. Recycled aluminum is also employed in the aerospace industry for aircraft parts due to its lightweight and high strength-to-weight ratio. Additionally, it's used in packaging, reducing waste and conserving resources. In electronics, recycled aluminum is used in the manufacturing of various components, contributing to the circular economy.</p>

- Q: Is aluminum a suitable material for use in electronic components or devices?

- <p>Yes, aluminum is used in electronics, primarily for its excellent thermal conductivity and electrical conductivity. It is commonly used in heat sinks to dissipate heat from electronic components, such as CPUs and power transistors. Additionally, aluminum is utilized in capacitors and as a conductor in wiring due to its low electrical resistance. However, it is not used as widely as copper for electrical conductivity applications due to copper's superior properties.</p>

- Q: Is there a more environmentally friendly method for recycling aluminum?

- <p>Yes, aluminum can be recycled in a more environmentally friendly way. The process of recycling aluminum is already quite efficient, as it requires only 5% of the energy needed to produce new aluminum from raw materials. However, further improvements can be made by optimizing recycling processes, reducing transportation emissions, and increasing the use of recycled aluminum in new products. Additionally, implementing closed-loop recycling systems where aluminum is continuously recycled without loss in quality can minimize waste and environmental impact. Educating consumers about the importance of recycling and improving collection systems can also contribute to more sustainable aluminum recycling practices.</p>

Send your message to us

Aluminum PVDF Coated Composite Panels - Good Quality and Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches