PVDF Aluminium Composite Panel with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

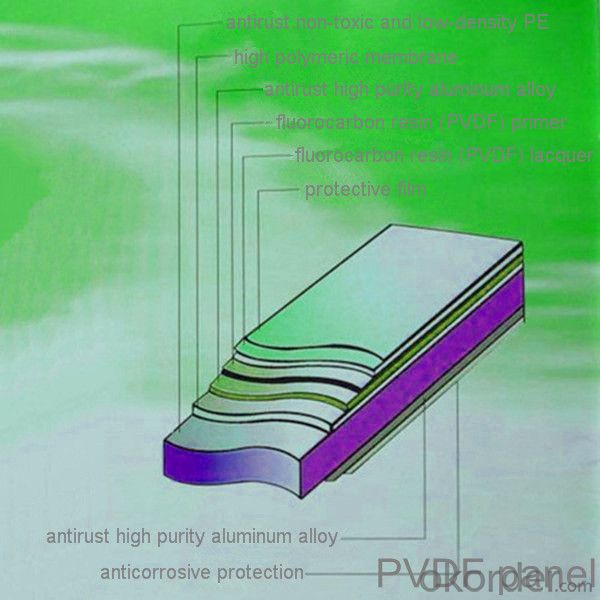

1.Structure of PVDF Aluminium Composite Panel Description:

By adopting PVDF paints from the two toppest paint supplier: American PPG and Sweden Beckers, Megabond PVDF Aluminum Composite Panel is the most ideal material for facade cladding, curtain wall cladding and other outdoor using purpose.

PVDF is short for Polyvinlylidene Fluoride, the color will have no obvious change within 15 to 20 years when it’s applied outdoor. PVDF paint should be 2-layer coating or 3-layer coating, and Painting Thickness ≥25um., Fluorocarbon Powder ≥70%.

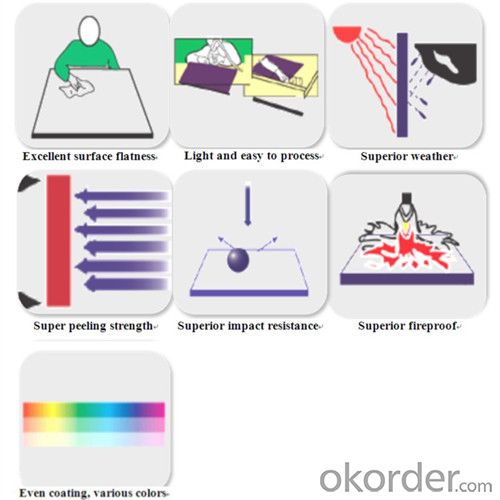

2.Main Features of the PVDF Aluminium Composite Panel :

1) Building exterior curtain wall, purdah wall;

2) Decoration and renovation additions for old buildings;

3) Decorations of interior walls (ceilings, partitions, bathrooms, cabinet, counter,

video wall, shield for doors windows, skirting, kitchens and balconies.)

4) Shop door decorations;

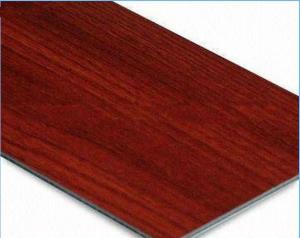

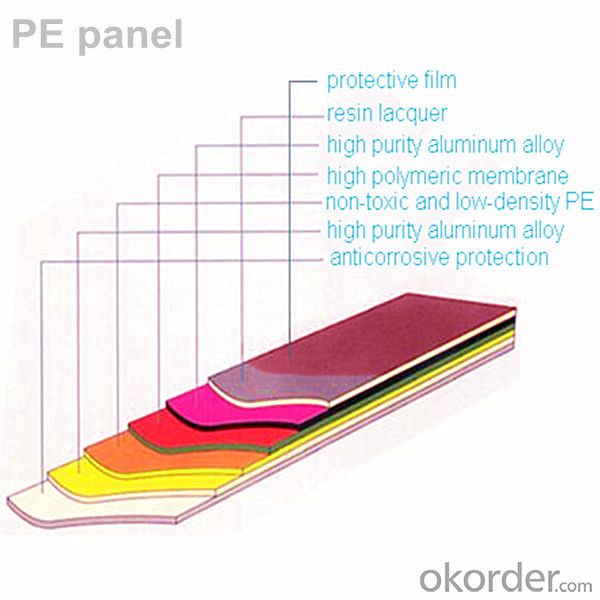

3. PVDF Aluminium Composite Panel Image:

4. PVDF Aluminium Composite Panel Specification

| Aluminum alloy | AA1100 series,AA3003 series |

| Aluminum skin | 0.30mm,0.40mm,0.45mm,0.50mm |

| Thickness | 4mm,5mm,6mm |

| Width | 1220mm,1250mm,1500mm,1575mm |

| Length | up to 6000mm |

| Color | 30 kinds.Special color available upon request |

5.FAQ

1).How to choose the panel thickness for different usages?

Exterior usage: 4mm panel with 0.30mm,0.40mm or 0.50mm aluminum skin, better in PVDF coating.

Interior usage: 3mm panel with 0.10mm,0.15mm or 0.21mm aluminum skin, PE coating is ok.

2). How to check whether this product is in good quality?

A. First is to see whether the surface is smooth enough, no ripples, bubbles and scratches.

B. Second is to check whether the panel thickness and aluminum skin thickness is thick enough.

C. To check the core material, whether it's easy broken.

D. To test the peel strength between aluminum skin and the core .

E. See whether company is normal manufacturer, which have ISO, CE, SGS certificate.

....

3). How to confirm the color for what you want?

You can contact me for our color card.

You can also choose a color from the RAL/Panton color card.

- Q: Can aluminum plate prevent radiation?

- Probably only the lead plate to radiation, did not hear that there are other materials have this performance.

- Q: In the curtain wall applications, aluminum veneer and aluminum plate which is better?

- Combined with the current mainstream of the curtain wall material, aluminum veneer will be better, after all, from the cost, technology, and the effect, recycling and so have a remarkable place.

- Q: What are the chemical composition of aluminum veneer for building decoration

- Aluminum curtain wall with its excellent physical characteristics, rapid processing and assembly, excellent fire performance, advanced surface treatment technology and glittering metallic color, in today's architectural decoration is widely used, especially the aluminum curtain wall and glass curtain wall Perfect combination, so that the building and the surrounding environment more coordinated, more elegant, luxurious.

- Q: Aluminum veneer and aluminum sheathed which fire?

- No fire under the fire!

- Q: What is aluminum plastic plate?

- Aluminum plastic plate, also known as aluminum-plastic composite panels, the middle is plastic, covered with thin aluminum plate and hot pressed together with the composite board

- Q: OKorder Province, the price of aluminum-plastic plate market how? There is no sale of aluminum-plastic plate manufacturers can give a price list of aluminum-plastic plate

- OKorder side seems to have a lot of money in Kunming side of the purchase, you can go there to see the rain dragon, where there is a building city, do not know if you ask me

- Q: High-rise building (18 layers) external wall with the price of aluminum-plastic plate between the number of?

- Aluminum-plastic plate specifications are 1.2X2.4, single-sided 50 yuan / Zhang, double-sided, raw rubber, 10 silk is 80 yuan / Zhang; double-sided, cooked plastic, 10 silk 100 yuan / Zhang; Silk 150 yuan / Zhang, 24 silk 220 yuan / Zhang, there are a lot of specifications are not listed one by one

- Q: OKorder red fruit which point outside the pillars of the package, aluminum-plastic plate to sell?

- Are generally in the cloud like to get goods

- Q: What is aluminum plastic material?

- Aluminum-plastic composite board is a chemically treated coated aluminum sheet for the surface material, with polyethylene plastic as the core material, in the special aluminum-plastic plate production equipment from the processing of composite materials. The unique performance of the aluminum-plastic composite panel itself determines its wide range of uses: it can be used for building facades, curtain wall panels, retrofits of old buildings, interior walls and ceilings, advertising signs, display stands, engineering. Aluminum-plastic composite panels in the country has been widely used, belonging to a new type of building decoration materials.

- Q: Chengdu Deyang made of external walls of aluminum-plastic package material how much money a square

- Our common offer is 350 yuan / square meter or more, the highest is 800 yuan / square meter. Generally in the 450 yuan / square meter more reasonable. Can use real material.

Send your message to us

PVDF Aluminium Composite Panel with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords