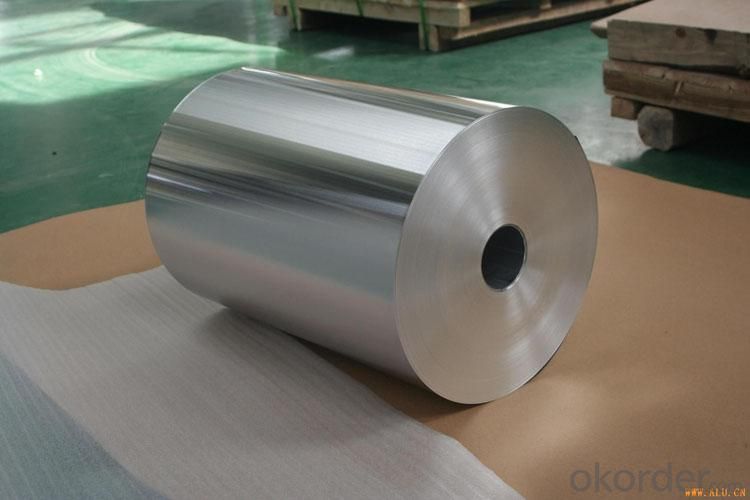

Aluminum Lacquered Lidding Foil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons pc

- Supply Capability:

- 1000 Tons Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick details of Aluminum foil for Lacquered Lidding Foil

|

Application: |

Lid of yogurt package, dairy package |

|

Alloy: |

8006/8011/ 8079 |

|

Temper: |

O |

|

Thickness& Tolerance: |

0.03mm-0.05mm (±5%) |

|

Width& Tolerance: |

200-1650mm (±1mm) |

|

Lacquer: |

HSL for PP/PS |

|

Primer: |

Primer for printing |

|

Standard: |

GB/T3198 / ASTM-B209 / EN546 |

Usage/Application of Aluminum foil for Lacquered Lidding Foil

Used for Lid of yogurt package, dairy package

Packaging & Delivery of Aluminum foil for Lacquered Lidding Foil

Packing: seaworthy wooden box with pallet

Delivery: to be loaded by 1 x 20 feet container

- Q: Explain the impact of adding magnesium to aluminum alloys on their characteristics.

- <p>Adding magnesium to aluminum alloys significantly enhances their strength, especially in the form of heat-treatable alloys known as Al-Mg or 5000 series alloys. Magnesium increases the alloy's resistance to corrosion, improves its formability, and raises its mechanical strength. These alloys are often used in applications requiring high strength-to-weight ratios, such as in the aerospace and automotive industries. The addition of magnesium also improves the alloy's weldability and resistance to stress corrosion cracking. However, it's important to note that excessive magnesium can lead to reduced ductility and increased susceptibility to stress corrosion cracking, so the amount added must be carefully controlled.</p>

- Q: Explain the distinction between pure aluminum and aluminum alloys, focusing on their composition and properties.

- <p>Pure aluminum is composed of aluminum alone, with a high degree of purity, typically over 99%. It is soft, malleable, and has good thermal and electrical conductivity. Aluminum alloys, on the other hand, are made by combining aluminum with other elements such as copper, magnesium, or silicon to enhance their strength, durability, and resistance to corrosion. These alloys are harder than pure aluminum and can be tailored for specific applications, making them more versatile for industrial use.</p>

- Q: Besides other special pots, can other aluminum pots be used?

- Electromagnetic stove pot must be metal pot with magnetic and non-magnetic stainless steel, aluminum pot can not be used.

- Q: What are the methods to prevent aluminum from corroding?

- <p>To prevent aluminum from corroding, several methods can be employed. One effective method is anodizing, which involves applying a protective oxide layer on the aluminum surface to enhance its resistance to corrosion. Another approach is using protective coatings such as paints or enamels that act as a barrier against corrosive elements. Additionally, alloying aluminum with other metals can improve its corrosion resistance. Regular cleaning and maintenance, avoiding contact with corrosive substances, and controlling environmental conditions such as humidity can also help in preventing corrosion.</p>

- Q: What are the various applications and benefits of using aluminum in the automotive industry?

- <p>Aluminum is widely used in automobiles for its lightweight properties, which improve fuel efficiency and reduce emissions. It's used in engine parts, such as pistons and cylinder heads, to decrease weight and increase performance. Aluminum is also used in body panels, wheels, and suspension components, enhancing vehicle handling and reducing unsprung weight. Additionally, aluminum's corrosion resistance makes it ideal for exterior parts, and its recyclability aligns with environmental sustainability efforts in the automotive industry.</p>

- Q: Is it safe to use aluminum for making containers for food and beverages?

- <p>Yes, aluminum can be used to make containers for food and drink. Aluminum is a common material for food packaging due to its lightweight, durability, and resistance to corrosion. It forms a protective oxide layer that prevents the metal from interacting with the food, ensuring safety. However, it's important to note that aluminum containers should not be used for storing acidic foods or beverages for extended periods, as this can lead to leaching of aluminum into the food. Additionally, some studies suggest a potential link between aluminum and neurological disorders, though this is still a subject of debate.</p>

- Q: This question asks about the impact of aluminum on the aging process in living organisms.

- <p>Aluminum's effect on the aging process is a subject of ongoing research and debate. Some studies suggest that aluminum can accumulate in the body over time, potentially contributing to age-related diseases such as Alzheimer's. It is hypothesized that aluminum may interfere with cellular function, disrupt enzyme activity, and cause oxidative stress, which are all factors associated with aging. However, the exact mechanisms and the extent of aluminum's role in aging are not fully understood. It's important to note that the human body naturally has mechanisms to excrete aluminum, and the contribution of aluminum to aging is not conclusively proven. More research is needed to establish a clear link between aluminum exposure and the aging process.</p>

- Q: This question asks to outline the various environmental effects that result from the production of aluminum.

- <p>Aluminum production has several environmental impacts. It is energy-intensive, leading to high greenhouse gas emissions, primarily CO2, contributing to climate change. The process also generates toxic byproducts such as fluorides and cyanides, which can contaminate soil and water. Biodiversity is affected due to habitat destruction from mining activities. Additionally, aluminum production consumes significant amounts of water, which can strain local water resources. The industry also contributes to air pollution through the release of particulate matter and other pollutants. Overall, aluminum production poses a significant environmental challenge that requires sustainable practices and technologies to mitigate its impacts.</p>

- Q: What are the ecological effects and consequences of producing aluminum?

- <p>The environmental impact of aluminum production is significant and multifaceted. It involves high energy consumption, primarily from the electricity needed for the electrolytic process to extract aluminum from bauxite. This contributes to greenhouse gas emissions, particularly if the electricity is generated from fossil fuels. The process also generates hazardous waste, such as red mud, which contains heavy metals and can pollute water sources if not properly managed. Additionally, deforestation and habitat destruction occur due to bauxite mining, affecting biodiversity. Lastly, aluminum production contributes to air pollution with the release of particulates and other pollutants.</p>

- Q: Why is syNeo, unlike most other aluminum salt antiperspirant, designed to prevent perspiration while removing odors and to best fit the skin?

- This has been very good at inhibiting perspiration, and there is no need to use other antiperspirant.

Send your message to us

Aluminum Lacquered Lidding Foil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons pc

- Supply Capability:

- 1000 Tons Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords