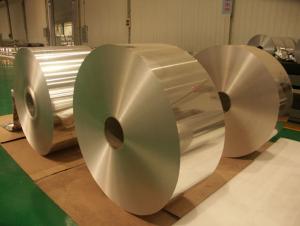

Aluminium Foilstock for Lamination

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 MT / Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Aluminium Foil Stock for Lamination Foil

Alloy: 8079 / 8011 / 1235

Temper: H14 / H16 / H24 / H26

Specifications of Aluminium Foil Stock for Lamination Foil

Thickness & Tolerance: 0.28 mm - 0.3 mm (+/-0.01%)

Width & Tolerance: 1000 - 2020 mm (+/-1 mm)

Core I.D.: 405/505/508 mm

Surface Quality: Good appearance with no-crack and well distribute grain

Build Up: Tight slit edges free from cracks, layer to layer shift not more then 2 mm

Flatness: Mill flatnesscoil having slight edge waviness rather than center buckles shall be acceptable

Rolling Performance: Re-rollable to the final desired gauges

Standard: GB/T3198 / ASTM-B209

Usage/Application of Aluminium Foil Stock for Lamination Foil

To produce aluminium foil for lamination foil application

Packaging & Delivery of Aluminium Foil Stock for Lamination Foil

- Q: This question asks about the interaction between aluminum and electromagnetic radiation, specifically how aluminum influences or is affected by such radiation.

- <p>Aluminum has a high electrical conductivity and is a good reflector of electromagnetic radiation. It reflects a wide range of frequencies, including visible light, ultraviolet, and infrared radiation. Due to its reflective properties, aluminum is used in applications such as reflective coatings for insulation and mirrors. It also has the ability to shield against electromagnetic radiation, making it a common material in the construction of Faraday cages, which are used to block external electromagnetic fields. Aluminum's effect on electromagnetic radiation is primarily through reflection and shielding, rather than absorption or transmission.</p>

- Q: Is it possible to repurpose or reuse old aluminum foil for various uses?

- <p>Yes, old aluminum foil can be repurposed for various uses. It can be recycled, used as a makeshift scrubber for cleaning, or as a reflector for grilling. You can also use it to cover food for storage or as a barrier in gardening to deter pests. However, it's important not to reuse foil that has held acidic or sugary foods, as it can corrode and release aluminum into the food. Always ensure the foil is clean and in good condition before repurposing.</p>

- Q: What other materials can be used as substitutes for aluminum in various applications?

- <p>Alternative materials to aluminum include magnesium, which is lighter and often used in automotive and aerospace applications; titanium, known for its strength and corrosion resistance, though more expensive; copper, utilized for its excellent electrical conductivity; and steel, which is stronger and more durable but heavier. Additionally, composite materials like carbon fiber and fiberglass offer weight savings and high strength, though they can be more complex to manufacture. Each alternative has its own set of advantages and disadvantages depending on the specific application and requirements.</p>

- Q: This question asks about the various applications of aluminum in the construction industry.

- <p>Aluminum is widely used in construction due to its lightweight, high strength, and corrosion resistance. It is commonly used in window frames, door frames, curtain walls, and roofing systems for its durability and energy efficiency. Aluminum is also utilized in structural components such as beams and columns, as well as in the manufacturing of prefabricated buildings. Additionally, it is used in the electrical wiring and conduits within buildings due to its excellent conductivity. Its versatility makes it a popular choice for both residential and commercial construction projects.</p>

- Q: What precautions should be taken when handling or working with aluminum?

- <p>When working with aluminum, several safety measures should be taken: Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a dust mask to prevent inhalation of aluminum dust. Ensure proper ventilation to avoid the buildup of dust or fumes. Use tools and equipment designed for aluminum to prevent sparks or heat buildup, which can cause fires. Store aluminum in a dry place to prevent corrosion. Always follow the manufacturer's guidelines for handling and processing aluminum, and be aware of the specific hazards associated with the aluminum products you are working with.</p>

- Q: Explain the differences between aluminum and other metals concerning their ability to degrade or break down in the environment.

- <p>Aluminum is not biodegradable in the traditional sense, meaning it does not break down into simpler substances through natural processes. It is highly resistant to corrosion and can persist in the environment for a long time. Unlike metals like iron, which rust and degrade over time, aluminum remains largely intact. However, aluminum can react with other elements in the environment, such as oxygen, to form a thin layer of aluminum oxide on its surface, which can alter its properties. Other metals like magnesium and zinc are more biodegradable as they can corrode and break down more readily in certain conditions, contributing to their use in biodegradable materials.</p>

- Q: This question asks about the consequences of corrosion on aluminum, including how it affects the material's properties and performance.

- <p>Corrosion on aluminum can lead to a loss of structural integrity, reduced strength, and increased brittleness. It can cause pitting, which is localized corrosion that leads to the formation of small holes or cavities on the surface. Over time, this can lead to material failure. Corrosion can also alter the appearance of aluminum, causing discoloration and a rough texture. In extreme cases, it can lead to the complete degradation of the aluminum, resulting in the loss of the material's functionality. Proper maintenance, such as applying protective coatings or using corrosion-resistant aluminum alloys, can mitigate these effects.</p>

- Q: This question asks for an explanation of the process involved in the production of aluminum foil.

- <p>Aluminum foil is made through a process that starts with the extraction of aluminum from its ore, bauxite. The bauxite is refined to produce aluminum oxide, which is then reduced to aluminum using the Hall-H茅roult process. The aluminum is then melted and cast into large ingots. These ingots are heated and rolled into thin sheets using large industrial rolling mills. The aluminum is rolled multiple times, each pass reducing its thickness until it reaches the desired foil thickness. The final thin sheets are then cut and packaged as aluminum foil. This process requires precision and control to ensure the foil is uniform and free of defects.</p>

- Q: Is it possible to enhance the efficiency of solar panels by utilizing aluminum?

- <p>Yes, aluminum can be used to improve the efficiency of solar panels. Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity, which can help in dissipating heat and maintaining optimal operating temperatures for solar cells. It is also used in the manufacturing of solar panel frames, providing structural support while reducing the overall weight of the panels. Additionally, some research suggests that using aluminum in the backsheet of solar panels can enhance their durability and efficiency. However, the extent of efficiency improvement depends on various factors, including the specific design and manufacturing process of the solar panels.</p>

- Q: Is it safe to utilize aluminum cookware in a microwave oven, considering potential hazards or damage?

- <p>Using aluminum pots and pans in a microwave oven is not recommended. Aluminum can cause sparks and potentially start a fire, as microwaves can reflect off metal surfaces and damage the microwave. Additionally, aluminum may not distribute heat evenly, leading to uneven cooking. It's safer to use microwave-safe cookware, such as glass or ceramic dishes, which are designed to withstand microwave heating without risk.</p>

Send your message to us

Aluminium Foilstock for Lamination

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 MT / Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords