PVDF Aluminum Composite Panel for Building Decorative

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Composite Panel(ACP/ACM) is Aluminum Composite material consisting of two aluminum cover sheets sandwiching a nontoxic low desity polyethylene core producted from a continuous extrusion process,when the ACM is used for external cladding of buildings&internal,it is usually called Aluminum Composite Panel,shortened as ACP

Application:Office Buildings,Shopping Centers,Industrial Buildings,Airports,Hotels,Bus center,Hospitals,Schools,Supermarkets,Resisdential Buildings

Description PVDF Aluminum Composite Panel details data given below

Width(mm) | 900mm | 1220mm | 1250mm | 1500mm | 2000mm | ||||

Length(mm) | 2440mm (standard length) | Or flexible | Any length can be done | ||||||

Panel thickness(mm) |

3mm

| 4mm | 5mm | 6mm | (4mm outdoor, 3mmindoor) | ||||

Aluminum thickness(mm) | 0.21mm, 0.25mm, 0.30mm, 0.35mm, 0.40mm, 0.45mm, 0.5mm | ||||||||

Coating | PVDF | BRUSHED | |||||||

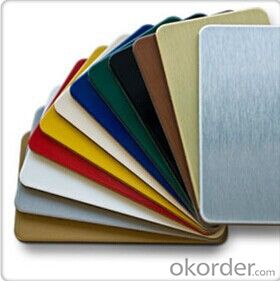

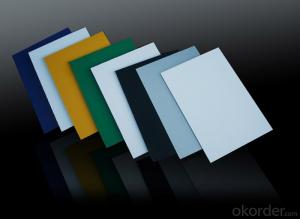

Color | metallic color solid color brush color marble timber color spectra sparking | RAL COLOR CAN BE DONE | |||||||

Weigth | 5-6.5kg/square meter based on 4mm thickness | 3-4.5kg/square meter based on 3mm thickness

| |||||||

Aluminum composite products display

Testing of Aluminum Composite panel

loading of Aluminum Composite panel

A. In bluk---can load more panels, but need manual unloading.

B. In wood pallets----load less panels than bulk load, but convenient in unloading.

C. Wood boxes----usually for LCL load, to protect panels from damage on the way.

1. How to choose the panel thickness for different usages?

Exterior usage: 4mm panel with 0.30mm,0.40mm or 0.50mm aluminum skin, better in PVDF coating.

Interior usage: 3mm panel with 0.10mm,0.15mm or 0.21mm aluminum skin, PE coating is ok.

2. How to check whether this product is in good quality?

A. First is to see whether the surface is smooth enough, no ripples, bubbles and scratches.

B. Second is to check whether the panel thickness and aluminum skin thickness is thick enough.

C. To check the core material, whether it's easy broken.

D. To test the peel strength between aluminum skin and the core .

E. See whether company is normal manufacturer, which have ISO, CE, SGS certificate.

3. How to confirm the color for what you want?

You can contact me for our color card.

You can also choose a color from the RAL/Panton color card

4. More questions, please contact me....

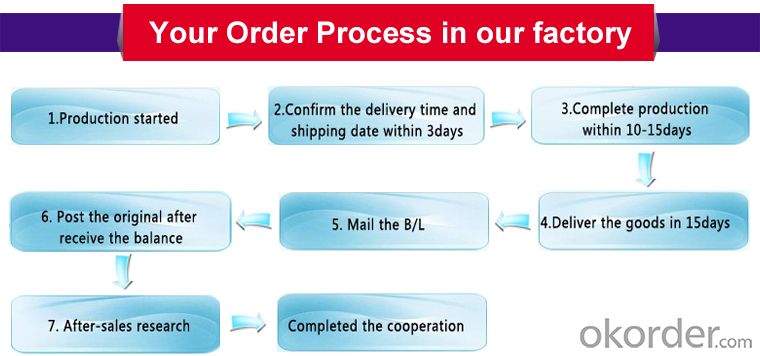

Our sevice of Aluminum Composite Panel

Our TWO Advantages:

No.1 located in Free tarde zone, save taxes, governmnet support, reduce cost.

No.2 Raw material produced by ourselves, reduce cost.

Linyi Jinhu Color Coating Aluminum Industry Co.,Ltd., located in Linyi Free Trade Zone, is the largest aluminum composite panel (ACP) manufacturer with 12 world advanced production lines and annual output of 18 milion square meters, including Interior and Exterior ACP,Fireproof ACP and NANO self-cleaning ACP.

It has a team of senior professional technicians, experienced managers and excellent marketing personnel, own the most advanced Automatic hot pressing ACP production line, high speed coating production line and corresponding supporting facilities in China, which guarantee the high quality and competitive advantage of our products.

Wellcome you visit US

- Q: China aluminum-plastic plate door decoration materials, where to buy a good point? Have prawn help?

- To Kunming cloud like building materials to buy, they are a set of aluminum-plastic plate, aluminum veneer production and wholesale as one of the large curtain wall decoration materials business, the introduction of the quality of aluminum-plastic plate is very good.

- Q: Aluminum plate, aluminum plate, aluminum square plate What is the difference

- Aluminum plate is made of aluminum, thick, suitable for large area, outdoor ceiling; aluminum plate with aluminum plate, are thin material, suitable for interior decoration ceiling!

- Q: What is the difference between stretching aluminum and hot-rolled aluminum? What is the concept of stretching aluminum?

- There is also a pre-stretched aluminum plate is relatively hard aluminum alloy (there are several grades), is in the production process to increase the stretch of this process, in order to eliminate the aluminum plate stress and strengthen the flatness of it.

- Q: Aluminum-plastic composite panels and insulation materials have some requirements, such as the layout to 1150mmx2200mm can be reinforced, reinforced strength can meet the requirements?

- We have customers have done 4 meters wide

- Q: I would like to open an aluminum-plastic plate of the store, who knows Zhejiang side there is no SHJIX OKorder auspicious manufacturers?

- If you want to agent in the high-end brands, then you can choose Huatian aluminum aluminum plate. Sinopec and KFC are the first use of our door

- Q: Astella aluminum plate 3 plywood price how much ah?

- Atari factory in Foshan Nanhai Luo Village, you can call to ask.

- Q: China where auspicious aluminum-plastic plate manufacturers? I have a lot of aluminum plastic panels.

- In China's words there is no auspicious aluminum-plastic plate manufacturers

- Q: From the aluminum plate on the separation of aluminum, can sell how much money? What factory to ,, Thank you

- Aluminum ingot manufacturers want.

- Q: Whether the aluminum plate is non-combustible material

- Can provide non-combustible grade aluminum composite plate material, but can not say that aluminum-plastic plate is non-combustible material.

- Q: Aluminum plate how much money

- Double-sided good about 210 one

Send your message to us

PVDF Aluminum Composite Panel for Building Decorative

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords