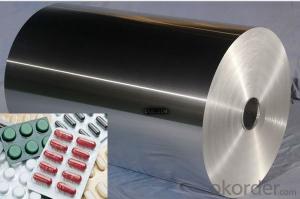

Aluminum Pharmaceutical Foil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 MT m.t.

- Supply Capability:

- 7000MT/MONTH m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick details of Pharmaceutical Foil

Alloy: 8011/8006/8079

Temper: H18/O

Specifications of Pharmaceutical Foil

Thickness & Tolerance: 0.02mm-0.09mm (±6%)

Width & Tolerance: 200mm-1650mm (±1mm)

Mechanical Properties: Tensile Strength(U.T.S)≥160Mpa, Elongation≥1%

Standard: GB/T3198 / ASTM-B209 / EN546

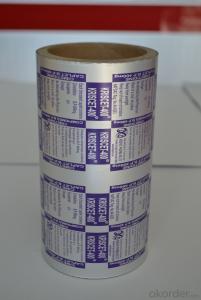

Usage/Application of Pharmaceutical Foil

For for PTP foil, cord-forming foil, alu-alu foil

Packaging & Delivery of Pharmaceutical Foil

Packing: seaworthy wooden box with pallet

Delivery: to be loaded by 1 x 20 feet container

- Q: Is it possible to utilize aluminum as a material for manufacturing solar cells?

- <p>Aluminum is not typically used to make solar cells due to its properties. Solar cells are usually made from materials like silicon, which is a semiconductor and can efficiently convert sunlight into electricity. Aluminum, being a good conductor, is used in the manufacturing process of solar cells for its electrical conductivity, but not as the active material that generates electricity. It is used in the form of aluminum paste in the back surface field of solar cells to create a conductive layer and in the frame to provide structural support. However, for the photovoltaic conversion process itself, other materials are more suitable.</p>

- Q: Explain the distinction between aluminum as a pure element and its alloys.

- <p>Aluminum is a lightweight, silvery-white metal found in the Earth's crust. It is a pure element with the symbol Al and atomic number 13. Aluminum alloys, on the other hand, are mixtures of aluminum with other elements such as copper, magnesium, manganese, and silicon. These alloys are created to enhance certain properties like strength, durability, and resistance to corrosion. While pure aluminum is soft and malleable, its alloys are stronger and more versatile, making them suitable for a wide range of applications from aerospace to construction.</p>

- Q: Is it safe and common to use aluminum for the production of containers for food and beverages?

- <p>Yes, aluminum is commonly used to make containers for food and beverages. It is lightweight, durable, and provides excellent resistance to corrosion. Aluminum cans are widely used for beverages like soda and beer, and aluminum foil is often used for food packaging. However, it's important to note that the interior of aluminum cans is usually lined with a protective coating to prevent direct contact with the food or drink, which can help to mitigate any potential health concerns related to aluminum exposure.</p>

- Q: Is it possible to utilize aluminum in the manufacturing of tools and equipment?

- <p>Yes, aluminum can be used to make tools and equipment. It is valued for its lightweight, corrosion resistance, and high strength-to-weight ratio. Aluminum is commonly used in various applications such as aircraft manufacturing, automotive parts, and consumer electronics. It is also used in the construction of certain types of tools, particularly those that require lightness and durability without the need for extreme strength. However, for applications requiring high strength or resistance to high temperatures, other materials might be more suitable.</p>

- Q: This question asks if there are any health risks related to cooking with pure aluminum pots and pans.

- <p>There are potential health risks associated with using pure aluminum pots and pans for cooking. Aluminum can leach into food, especially in acidic environments, which may lead to increased aluminum intake. High levels of aluminum in the body have been linked to neurological disorders, including Alzheimer's disease, although the connection is not definitively proven. Additionally, aluminum can interfere with the absorption of certain minerals, such as calcium and iron. For these reasons, it is generally recommended to use cookware made from materials that do not leach, such as stainless steel, cast iron, or non-stick coatings, to minimize exposure to aluminum.</p>

- Q: This question asks for a list of typical flaws or imperfections that can occur in aluminum products.

- <p>Common defects in aluminum products include porosity, which refers to small holes or voids within the material; surface defects such as scratches, dents, and discoloration; mechanical defects like warping or deformation; and metallurgical defects such as inclusions or impurities. Additionally, aluminum products can suffer from corrosion, which can lead to pitting or general surface degradation, and stress corrosion cracking, which occurs under certain environmental conditions and stress. Each of these defects can impact the structural integrity, appearance, or performance of aluminum products.</p>

- Q: Angell doors and windows as a door brand, compared to other aluminum alloy doors and windows what are the advantages?

- Patterns, products, services have advantages, you can go to their official website to see.

- Q: What are the environmental impacts of aluminum production and use?

- <p>Aluminum has significant environmental impacts, primarily due to its production process. The extraction of bauxite ore, the main source of aluminum, involves deforestation and habitat destruction. The refining process releases greenhouse gases, particularly carbon dioxide, contributing to climate change. Additionally, aluminum production generates toxic byproducts like red mud, which can contaminate water and soil. Despite these issues, aluminum is also recyclable, and its lightweight nature can reduce energy consumption in transportation, mitigating some environmental impacts. However, improper disposal of aluminum waste can still lead to pollution.</p>

- Q: This question asks for a comparison of the benefits and drawbacks of using aluminum foil in the culinary process.

- <p>Aluminum foil offers several advantages in cooking, such as easy clean-up, even heat distribution, and the ability to create a seal for steaming or baking. It's also versatile, being suitable for both roasting and wrapping food for baking. However, there are disadvantages, including potential health concerns due to the leaching of aluminum into food, especially at high temperatures. Additionally, foil can tear easily, and it's not suitable for non-stick surfaces or use under broilers. Environmentally, it's not biodegradable and contributes to waste, which is a significant disadvantage.</p>

- Q: Is aluminum a suitable material for use in electronic components or devices?

- <p>Yes, aluminum is used in electronics, primarily for its excellent thermal conductivity and electrical conductivity. It is commonly used in heat sinks to dissipate heat from electronic components, such as CPUs and power transistors. Additionally, aluminum is utilized in capacitors and as a conductor in wiring due to its low electrical resistance. However, it is not used as widely as copper for electrical conductivity applications due to copper's superior properties.</p>

Send your message to us

Aluminum Pharmaceutical Foil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 MT m.t.

- Supply Capability:

- 7000MT/MONTH m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords