Aluminum Composite Panel Wall Cladding ACP - Good Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

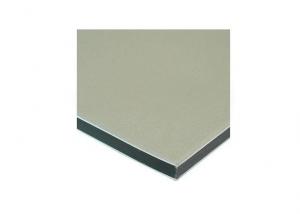

Structure of ACP Description:

Aluminum Composite Panel is a composite material made of aluminum and non-combustible mineral filled core. Though the core material does contain a small amount of combustible polyethylene, the main ingredient of the non-combustible mineral filled core does not permit the proliferation of flame and restricts smoke. It is a fire-safe material that passes mandatory requirements for exterior and interior application.It is an ideal material for external claddings, roof of pedestrian passage and other architectural applications.

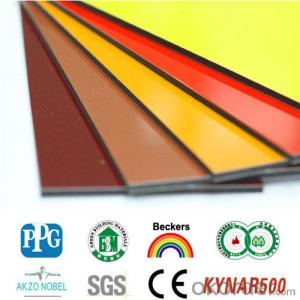

Main Features of ACP:

1) Super werther resistance

2) Light weight easy to process

3) Excellent fire resistance

4) Excellent impact strength

5) Uniform and colorful coating

6) Easy maintenance...and so on

7) Within 15 work days after receiving the first deposite payment .

Images of ACP:

ACP Specifications:

Standard size | 1220*2440*3mm and 1220*2440*4mm |

Accepted Width | Max:1580mm |

Accepted Length | Max:6000mm |

Accepted Thickness | 2mm,3mm,4mm,5mmm,6mm |

Aluminum alloy thickness | 0.10mm0.15mm0.18mm0.21mm0.25mm0.3mm0.35mm0.40mm0.45mm0.50mm |

Weight | 5 kg/m2 base on 4*0.4mm |

Nonstandard | sizes are available according your requirement |

FAQ of ACP:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 20000㎡.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: What are the distinctions between aluminum foil and aluminum sheet in terms of thickness, usage, and properties?

- <p>Aluminum foil and aluminum sheet are both made from aluminum but differ in thickness and usage. Aluminum foil is very thin, typically ranging from 0.0005 to 0.1 inches, and is used for food packaging, cooking, and insulation. It is lightweight, flexible, and has excellent barrier properties against light, air, and moisture. Aluminum sheet, on the other hand, is thicker, usually from 0.2 to 2 inches, and is used in construction, automotive, and aerospace industries due to its strength and durability. It is less flexible than foil but offers greater rigidity and can withstand higher temperatures and pressures.</p>

- Q: This question asks for a list of typical aluminum alloys that are widely used in various industries.

- <p>Common types of aluminum alloys include 1000 series, which are nearly pure aluminum; 2000 series, known for their strength due to copper content; 3000 series, which are alloyed with manganese for good formability; 5000 series, featuring magnesium for improved strength and corrosion resistance; 6000 series, which are popular for their strength and heat treatability; and 7000 series, recognized for their highest strength among aluminum alloys, often used in aerospace and automotive applications. Each series offers unique properties that make them suitable for specific applications.</p>

- Q: How can we improve the efficiency and effectiveness of aluminum recycling?

- <p>Yes, there are several ways to recycle aluminum more efficiently and effectively. First, increase consumer awareness about the benefits of recycling aluminum and the importance of proper sorting. Second, invest in advanced recycling technologies that can process aluminum more quickly and with less waste. Third, collaborate with manufacturers to design products that are easier to recycle and made from more recycled content. Lastly, improve collection systems to ensure a higher percentage of aluminum waste is captured and recycled. These steps can significantly boost aluminum recycling rates and sustainability.</p>

- Q: This question asks about the environmental effects caused by the extraction and processing of aluminum.

- <p>The environmental impacts of mining and processing aluminum are significant. Mining can lead to deforestation and habitat destruction, affecting biodiversity. The process of bauxite extraction releases large amounts of greenhouse gases, contributing to climate change. Additionally, the production of aluminum is energy-intensive, often relying on fossil fuels, which further exacerbates environmental issues. The release of toxic chemicals and heavy metals during processing can contaminate soil and water, posing risks to both ecosystems and human health. Moreover, the waste generated, such as red mud, can cause severe environmental damage if not properly managed. Overall, the aluminum industry has a substantial environmental footprint that requires sustainable practices to mitigate its effects.</p>

- Q: This question asks for examples of industrial processes that incorporate the use of aluminum.

- <p>Aluminum is widely used in various industrial processes due to its lightweight, corrosion resistance, and high strength-to-weight ratio. Some key industrial processes that utilize aluminum include the automotive industry for manufacturing car parts, the aerospace industry for aircraft construction, the construction industry for building materials, the packaging industry for food and beverage cans, and the electronics industry for components in devices. Aluminum is also used in the manufacturing of machinery, electrical equipment, and transportation equipment. Its versatility makes it a crucial material in many industrial applications.</p>

- Q: This question asks about the impact of aluminum on human health when it is ingested through food packaged in aluminum containers.

- <p>Aluminum is a common element found in the environment, and it is naturally present in small amounts in many foods. When food is packaged in aluminum, there is a possibility of trace amounts of aluminum leaching into the food, particularly in acidic foods. While the human body can handle small amounts of aluminum without harm, excessive intake over a long period may lead to potential health concerns. Aluminum has been associated with neurological disorders, although the evidence is not conclusive. It's important to note that the risk is generally low, as the body does not absorb a significant amount of aluminum from food or packaging. However, it is always recommended to follow food safety guidelines and use packaging materials that are deemed safe for food contact.</p>

- Q: Is it safe to use pure aluminum for baking or roasting food in a traditional oven or grill?

- <p>While pure aluminum is a common material in cookware, it's not recommended for direct use in baking or roasting food in a traditional oven or grill. Aluminum can react with acidic foods, potentially leaching aluminum into the food. Additionally, aluminum foil can burn and create a hazardous situation. For baking or roasting, it's safer to use materials specifically designed for these purposes, such as parchment paper, silicone baking mats, or oven-safe dishes.</p>

- Q: This question asks for an explanation of the process involved in the production of aluminum foil.

- <p>Aluminum foil is made through a process that starts with the extraction of aluminum from its ore, bauxite. The bauxite is refined to produce aluminum oxide, which is then reduced to aluminum using the Hall-H茅roult process. The aluminum is then melted and cast into large ingots. These ingots are heated and rolled into thin sheets using large industrial rolling mills. The aluminum is rolled multiple times, each pass reducing its thickness until it reaches the desired foil thickness. The final thin sheets are then cut and packaged as aluminum foil. This process requires precision and control to ensure the foil is uniform and free of defects.</p>

- Q: This question asks for the specific temperature at which aluminum oxide transitions from a solid to a liquid state.

- <p>The melting point of aluminum oxide (Al2O3) is approximately 2072掳C (3767.6掳F). It is a high melting point due to the strong ionic bonds between aluminum and oxygen atoms in the crystal structure. This high melting point makes aluminum oxide a common material in high-temperature applications such as refractory materials and abrasives.</p>

- Q: This question asks for a comparison of the positive and negative aspects of using aluminum as a material.

- <p>Aluminum has several advantages, including its lightweight nature, making it ideal for transportation and construction. It is also highly recyclable, with the recycling process requiring less energy compared to many other materials. Additionally, aluminum is corrosion-resistant, which extends the lifespan of products. On the downside, aluminum is less strong than some other metals, which can limit its use in certain applications. It also has a high thermal conductivity, which can be a disadvantage in situations where insulation is needed. Moreover, aluminum production is energy-intensive, contributing to environmental concerns.</p>

Send your message to us

Aluminum Composite Panel Wall Cladding ACP - Good Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords