Quality Aluminum Coil - PVDF Coated Aluminum Sheet for HVAC Equipments

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PVDF Coated Aluminium Sheet For HAVC Equipment

Specifications

Grade

| 1000 Series: 1050 1060 1070 1100 1200 1235 etc. 3000 Series: 3003 3004 3005 3104 3105 3A21 etc. 5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 etc. 6000 Series: 6061 6063 6082 6A02 etc. 8000 Series: 8006 8011 8079 etc. |

Thickness | 0.05~10mm |

Width | <1600mm |

Color | Metallic, Solid, RAL or by customer requirements |

Coating paint: | PVDF(Polyvinylidene Fluoride), PE(Polyester ) |

Coating thickness | as per customer’s request |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | Polyester18~25micron(EN ISO-2360:1995) PVDF25 ~35micron(EN ISO-2360:1995) |

Coating hardness | 2H |

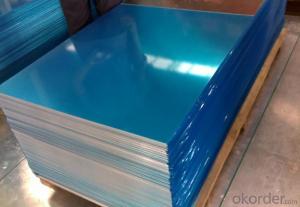

Protective film | PVC film, Colorless transparent or White-black |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

Temper | H16, H18, H24, H26, H26 |

Certification | ISO9001:2000, CE, SGS |

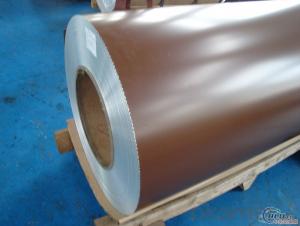

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

Payment | L/C ,T/T |

Application

1) Construction material further processing

2) Solar cell frame, solar battery frame

3) Glass curtain wall frame

4) Interior decoration

5) Elevator decoration

6) Signs, nameplate, bags making.

7) Automobile parts material

8) Office and Household appliances: HVAC equipments

9) The consumer electronics: mobile phones, digital cameras, MP3 .etc.

Coating varieties

Polyester Coatings (PE)

PE (polyester) coatings exhibit an excellent combination of hardness, flexibility, flow, appearance, and superior resistance to dirt retention in indoor and outdoor applications. These coatings are highly resistant to abrasion, metal marking, staining, and marring, and require minimal maintenance. Glazetech uses polyester paints which provide excellent colour and gloss retention properties.

Polyvinylidene Fluoride Coatings (PVDF)

PVDF (polyvinylidene fluoride) is a chemical resistant thick film barrier coating commonly used in architectural applications where both excellent appearance and substrate protection must be maintained over a long period of time. This coating is unaffected by most chemicals and solvents and has excellent wear and abrasion resistance. PVDF also has a high dielectric strength, excellent resistance to weathering and the ability to self extinguish.

- Q: Are aluminum coils suitable for architectural facades?

- Yes, aluminum coils are suitable for architectural facades. They are lightweight, durable, corrosion resistant, and can be easily formed into various shapes and sizes. Additionally, aluminum coils offer a wide range of finishes and colors, making them a versatile choice for architectural facades.

- Q: What are the typical standards and specifications for packaging aluminum coils?

- <p>The standard specification for aluminum coil packaging varies depending on the industry and region, but generally includes the following: The coil is typically wrapped in a protective film to prevent damage and corrosion. It is often strapped with steel or plastic bands to secure the coil during transportation. The packaging may also include wooden pallets or crates for stability. The dimensions and weight of the packaging are tailored to the coil's size and thickness. Compliance with international standards such as ASTM, ISO, or specific industry standards is crucial. It's important to note that exact specifications can differ based on customer requirements and the end-use application of the aluminum coil.</p>

- Q: Why the end of the aluminum coil will have a yellow spot?

- Without coolant processing one, to see if there is no stain, so you can engage in removal of cooling liquid is not interference. Blank surface should have a layer of alumina film processing, heat, such conditions should make the cooling liquid and the alkaline layer friction reaction

- Q: What kind of sensor is appropriate for aluminum coil thickness measurement?

- Optical sensor.

- Q: Can aluminum coils be used in the manufacturing of beverage cans?

- Indeed, beverage cans can be manufactured using aluminum coils. The utilization of aluminum in beverage can production is widespread owing to its multitude of benefits. Typically, aluminum coils are rolled into slender sheets, subsequently sliced, molded, and coated to achieve the final can structure. These coils offer a lightweight, sturdy, and resistant-to-corrosion material that is suitable for the storage and preservation of beverages. Moreover, aluminum is highly recyclable, rendering it an environmentally conscious option for the production of beverage cans.

- Q: This question asks for the current prices of aluminum coil in various regions around the world.

- <p>The price of aluminum coil can vary significantly based on factors such as market demand, supply, transportation costs, and regional economic conditions. Prices are typically quoted per metric ton and are influenced by the London Metal Exchange (LME) and regional metal exchanges. For the most accurate and up-to-date prices, it's best to consult with local metal suppliers or check online commodity trading platforms. Prices can change daily, so real-time data is essential for making informed decisions.</p>

- Q: Are aluminum coils suitable for insulation jacketing?

- Yes, aluminum coils are suitable for insulation jacketing. Aluminum is a popular choice for jacketing material due to its excellent thermal properties, durability, and corrosion resistance. It is widely used in various industries, including HVAC, oil and gas, and petrochemical, for insulating pipe systems and equipment. Aluminum coils provide a protective covering around insulation materials, preventing moisture ingress and maintaining thermal efficiency. Additionally, their lightweight nature makes them easy to install and transport. Overall, aluminum coils are a reliable and effective solution for insulation jacketing applications.

- Q: How are aluminum coils packaged for transportation?

- Aluminum coils are typically packaged for transportation by first being tightly wound and then securely strapped with steel bands. They are often placed on pallets and covered with protective materials such as plastic or cardboard to prevent damage during transit. Additionally, the coils may be loaded into containers or onto flatbed trucks, ensuring proper handling and stability throughout the transportation process.

- Q: Can aluminum coils withstand extreme temperatures?

- Aluminum coils have gained a reputation for their remarkable capability to endure extreme temperatures. With a melting point of 660.32°C (1220.58°F), aluminum proves to be an ideal material for tasks demanding heat resistance. HVAC systems, for instance, frequently employ aluminum coils that are exposed to both high and low temperatures. Similarly, automotive radiators rely on aluminum coils to withstand elevated operating temperatures. Moreover, the outstanding thermal conductivity of aluminum enables efficient heat transfer away from the coil, further bolstering its ability to withstand extreme temperatures. All in all, aluminum coils stand as a dependable and long-lasting option for applications that necessitate resistance to severe temperature conditions.

- Q: What are the common safety precautions when working with aluminum coils?

- Some common safety precautions when working with aluminum coils include wearing personal protective equipment such as gloves, safety glasses, and appropriate clothing to protect against cuts and burns. It is important to handle the coils with care to prevent injury, as they can be heavy and have sharp edges. Additionally, workers should be cautious when operating machinery or tools around the coils to avoid accidents. Proper ventilation should be ensured in the work area to prevent the buildup of fumes or dust. Lastly, workers should be trained on proper lifting techniques and be aware of the potential hazards associated with working with aluminum coils.

Send your message to us

Quality Aluminum Coil - PVDF Coated Aluminum Sheet for HVAC Equipments

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords