Number 4 Brushed Aluminum Sheets - Aluminium Coils with PVDF Coating 22-40 Microns

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

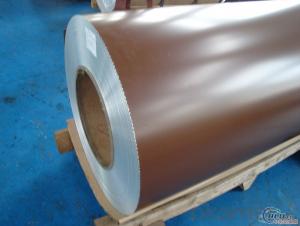

1.Structure of Aluminium Coils with PVDF Coating 22-40 microns

Aluminium Coils with PVDF Coating 22-40 microns are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Aluminium Coils with PVDF Coating 22-40 microns

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image of Aluminium Coils with PVDF Coating 22-40 microns

4. Product Specification of Aluminium Coils with PVDF Coating 22-40 microns

| Alloy | Temper | Thickness | Width | Coating Thickness |

| AA3003 | H14 | 0.2-3MM | 1000-1800MM | 20-25 MICRONS |

5.FAQ of Aluminium Coils with PVDF Coating 22-40 microns

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Describe the steps involved in installing aluminum sheets on a roof.

- <p>Installing aluminum sheets on a roof involves several key steps: 1) Inspect the roof structure to ensure it can support the new material. 2) Remove any existing roofing material. 3) Install roof underlayment to protect against moisture. 4) Position the first aluminum sheet at the lowest point of the roof, aligning it with the eaves. 5) Secure the sheet using clips or screws, ensuring a watertight seal. 6) Continue installing sheets up the roof, overlapping each by at least 2 inches for a secure fit. 7) Cut and fit sheets around vents, pipes, and other roof protrusions. 8) Install flashing and trim to finish edges and seal the roof. 9) Check for proper alignment and secure all fasteners. 10) Clean up debris and inspect the installation for any gaps or leaks.</p>

- Q: What are the potential health risks associated with handling aluminum sheets?

- <p>Working with aluminum sheets can pose certain health concerns, primarily due to inhalation of aluminum dust or fumes. Long-term exposure may lead to respiratory issues and potentially neurological problems. Aluminum dust can cause irritation to the eyes, nose, and throat. In some cases, it may contribute to the development of Alzheimer's disease, although this link is still debated. It's important to follow safety guidelines, such as using proper ventilation and wearing protective gear like masks and gloves, to minimize these risks.</p>

- Q: Can aluminum sheets be used for protective enclosures?

- Yes, aluminum sheets can be used for protective enclosures. Aluminum is a versatile and lightweight material that offers excellent durability and corrosion resistance. It can be easily fabricated into various shapes and sizes, making it suitable for constructing protective enclosures for a wide range of applications. Aluminum enclosures are commonly used in industries such as electronics, telecommunications, aerospace, and automotive. They provide protection against environmental elements, such as moisture, dust, and electromagnetic interference. Additionally, aluminum enclosures can be further enhanced with coatings or insulation materials to meet specific requirements for thermal insulation, fire resistance, or electrical conductivity. Overall, aluminum sheets are a reliable choice for protective enclosures due to their strength, versatility, and ability to withstand harsh conditions.

- Q: Are aluminum sheets suitable for water storage applications?

- Yes, aluminum sheets are suitable for water storage applications. Aluminum is a lightweight and durable material that is highly resistant to corrosion and rust. It is also impermeable to light, air, and water, making it an excellent choice for storing water. Additionally, aluminum sheets can be easily formed into various shapes and sizes, allowing for customizable water storage solutions.

- Q: Are aluminum sheets suitable for food processing applications?

- Yes, aluminum sheets are suitable for food processing applications. Aluminum is known for its excellent thermal conductivity and corrosion resistance, making it ideal for food industry processes such as cooking, baking, and packaging. Additionally, aluminum is a lightweight and cost-effective material that can be easily formed into various shapes and sizes, making it convenient for food processing equipment and utensils.

- Q: Can aluminum sheets be used for air ducts?

- Yes, aluminum sheets can be used for air ducts. Aluminum is a commonly used material for air ducts due to its lightweight and durable properties. It is resistant to corrosion, which makes it a suitable choice for HVAC systems. Aluminum sheets are often used to fabricate air ducts as they can be easily bent and shaped to fit the required dimensions. Additionally, aluminum has good thermal conductivity, allowing for efficient heat transfer within the ducts. Overall, using aluminum sheets for air ducts is a practical and effective choice.

- Q: How to press multilayer aluminum sheets (aluminum sheet's thickness: 0.2mm) together and keep them inseperate after pressing?

- resistance welding usually overlays two pieces together and presses them, heating them to melting state through current, you can try multiple sheets.

- Q: How do you prevent oxidation of aluminum sheets?

- To avoid oxidation of aluminum sheets, several techniques can be utilized. One commonly used method is to apply a protective coating or finish on the surface of the aluminum sheets. This coating acts as a barrier between the aluminum and the external environment, preventing the metal from reacting with oxygen and forming an oxide layer. There are various types of coatings available for this purpose, such as anodizing, painting, and powder coating. Anodizing involves creating a controlled oxide layer on the aluminum surface through electrolysis. This oxide layer is highly resistant to corrosion and provides excellent protection against oxidation. Painting and powder coating, on the other hand, involve applying a layer of paint or powdered polymer to the aluminum surface. These coatings create a physical barrier that shields the metal from oxygen and moisture. Another effective approach to prevent oxidation is by using aluminum alloys that have enhanced corrosion resistance. These alloys are specifically designed to have a higher resistance to oxidation and can withstand exposure to harsh environments without forming a significant oxide layer. In addition to coatings and alloy selection, proper storage and handling practices play a crucial role in preventing oxidation. It is important to store aluminum sheets in a clean, dry, and well-ventilated area to minimize exposure to moisture and corrosive elements. Contact with acidic or alkaline substances should be avoided, as they can accelerate the oxidation process. Regular cleaning and maintenance of aluminum sheets also help prevent oxidation by removing any contaminants that could promote corrosion. In summary, preventing oxidation of aluminum sheets involves a combination of protective coatings, appropriate alloy selection, and proper storage and handling practices. By implementing these measures, the lifespan and durability of aluminum sheets can be significantly improved.

- Q: Are aluminum sheets suitable for HVAC applications?

- Yes, aluminum sheets are suitable for HVAC applications. Aluminum is a lightweight, durable, and corrosion-resistant material, making it ideal for use in heating, ventilation, and air conditioning systems. It offers excellent thermal conductivity, allowing for efficient heat transfer, and can be easily formed and fabricated to meet specific requirements in HVAC installations. Additionally, aluminum is also environmentally friendly as it can be recycled, making it a sustainable choice for HVAC applications.

- Q: Can aluminum sheets be painted after installation?

- Yes, aluminum sheets can be painted after installation. Aluminum is a highly versatile and durable material that can be painted to enhance its appearance or match the surrounding environment. However, it is important to properly prepare the surface before painting to ensure adhesion and longevity of the paint. This typically involves cleaning the surface, removing any dirt or debris, and applying a suitable primer to promote better paint adhesion. Once the surface is prepared, any type of paint can be applied to the aluminum sheet, such as acrylic, oil-based, or epoxy paint. It is recommended to consult with a professional painter or follow the manufacturer's instructions for the specific paint product to achieve the best results.

Send your message to us

Number 4 Brushed Aluminum Sheets - Aluminium Coils with PVDF Coating 22-40 Microns

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords