Aluminum Corrugated Sheets for Cookware and Lighting Cover

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Description of Aluminium Circle for Cookware, Lighting Cover

Alloy: 1050, 1070, 1100, 3003, etc

Thickness: 0.5mm~4mm

Temper: O, H14

Diagonal: 100mm - 1200mm

2. Application of Aluminium Circle for Cookware, Lighting Cover

Aluminium Circle is widely used for kitchen wares including fried pans, non-sticky pans, cooking pots, hard anodize cook ware, pressure cooker and house hold utensils etc.

3. Feature of Aluminium Circle for Cookware, Lighting Cover

Aluminium Circle has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

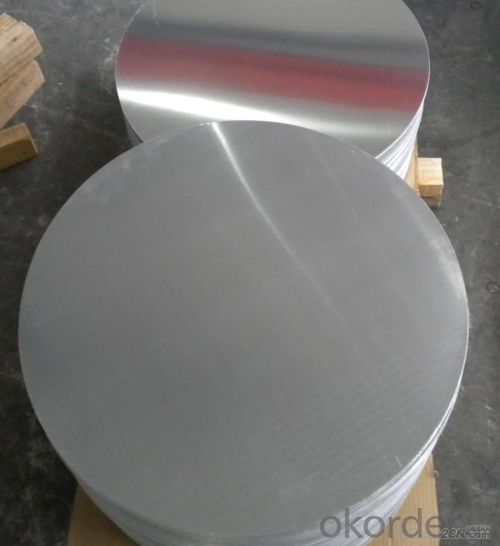

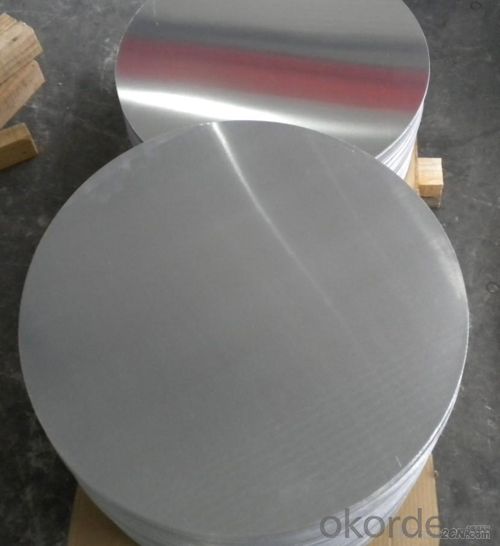

5. Image of Aluminium Circle for Cookware, Lighting Cover

6. Package and shipping of Aluminium Circle for Cookware, Lighting Cover

eye to Sky

eye to wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

- Q: General characteristics of pure aluminium plate of pure aluminium plate

- Comparison of pure aluminium sheets:1, grade: 1A85, 1A90, 1A93, 1A97, 1A99;Product type: plates, belts, foils, tubes;Main characteristics: Industrial high-purity aluminum;Applications: mainly used in the production of various electrolytic capacitor foil, acid fast container, etc., products have plates, belts, foils and so on.2, grade: 1060, 1050A, 1035;Product type: foil, wire;Main features: industrial pure aluminum has the characteristics of high plasticity, corrosion resistance, electrical conductivity and good thermal conductivity, but the strength is low, it can not be strengthened by heat treatment, cutting is not good. Acceptable contact welding and gas welding;Scope of application: use the advantages of making some structures with specific properties, such as aluminum foil gasket and capacitor, electronic tube isolation network, wire and cable protective sleeve, net, wire core and aircraft parts and trim ventilation system.3, brand: 1100;Product type: Sheet & strip;Main features: for ordinary industrial pure aluminum aluminum content of 99%, can not be strengthened by heat treatment; low strength, but has good ductility, formability, weldability and corrosion resistance; anodic oxidation can improve corrosion resistance, and beautiful surface;Scope of application: mainly produces sheet metal and strip. Suitable for making all kinds of deep stamping products, and is widely used in various fields from cooking utensils to industrial equipment.

- Q: Can aluminum sheets be used for protective enclosures?

- Aluminum sheets have the ability to be utilized for protective enclosures. This material, known for its versatility and lightweight nature, offers exceptional durability and resistance to corrosion. It can easily be transformed into various shapes and sizes, making it suitable for constructing protective enclosures across a wide range of applications. Industries such as electronics, telecommunications, aerospace, and automotive commonly employ aluminum enclosures, which safeguard against environmental factors like moisture, dust, and electromagnetic interference. Moreover, these enclosures can be further improved with the addition of coatings or insulation materials to meet specific requirements for thermal insulation, fire resistance, or electrical conductivity. All in all, aluminum sheets are a dependable option for protective enclosures due to their strength, adaptability, and capacity to endure challenging conditions.

- Q: What are the safety considerations when handling and working with aluminum sheets?

- When handling and working with aluminum sheets, there are several safety considerations that should be taken into account. Firstly, it is important to wear appropriate personal protective equipment (PPE). This includes safety glasses or goggles to protect the eyes from any potential flying debris or metal shards. Additionally, gloves should be worn to protect the hands from sharp edges or cuts. Secondly, it is crucial to handle aluminum sheets with care, as they can be quite sharp. When lifting or moving the sheets, it is recommended to use gloves and other tools to minimize the risk of injury. Additionally, it is important to be mindful of the weight of the sheets to avoid strains or back injuries. Another safety consideration is the potential for fire hazards. Aluminum is a highly flammable material, especially in the form of fine dust or shavings. Therefore, it is important to keep the work area clean and free from any loose aluminum debris. It is also advisable to have appropriate fire extinguishing equipment nearby and to be aware of the location of emergency exits. Furthermore, when cutting or shaping aluminum sheets, it is important to use proper techniques and tools. Using the appropriate saws or shears can help minimize the risk of injury. It is also important to secure the sheets properly to prevent them from moving or falling during the cutting process. Lastly, it is important to be aware of any potential health hazards associated with aluminum. Aluminum dust or fumes can be harmful if inhaled, so it is important to work in a well-ventilated area or use respiratory protection if necessary. In summary, the safety considerations when handling and working with aluminum sheets include wearing appropriate PPE, handling the sheets with care, minimizing fire hazards, using proper cutting techniques and tools, and being aware of potential health hazards. By following these precautions, the risks associated with working with aluminum sheets can be minimized, ensuring a safe working environment.

- Q: How does the grain structure of aluminum sheet affect its properties?

- The properties of aluminum sheet are greatly influenced by its grain structure. The arrangement of individual aluminum crystals, or grains, within the sheet is what determines this structure. The size, shape, and orientation of these grains can have an impact on the mechanical and physical properties of the aluminum sheet. For example, the sheet's strength, ductility, hardness, and corrosion resistance can all be affected by the grain structure. When it comes to strength, a fine-grained aluminum sheet tends to be stronger than one with coarse grains. This is because smaller grains result in more grain boundaries, which act as obstacles to the movement of dislocations and make the material more resistant to deformation. On the other hand, a coarse-grained structure has fewer grain boundaries, which leads to reduced strength. Additionally, the ductility of the aluminum sheet is influenced by its grain structure. Sheets with finer grains typically exhibit better ductility because the numerous grain boundaries hinder the motion of dislocations and prevent cracks from spreading. In contrast, coarser grains tend to promote crack propagation, resulting in reduced ductility. The hardness of the aluminum sheet is also affected by its grain structure. In general, a fine-grained structure contributes to higher hardness due to the increased density of dislocations and the strengthening effect of grain boundaries. Conversely, a coarse-grained structure leads to reduced hardness as there are fewer obstacles to dislocation motion. Furthermore, the grain structure plays a role in the corrosion resistance of the sheet. Fine-grained aluminum sheets tend to have better corrosion resistance compared to coarse-grained ones. This is because the presence of more grain boundaries in fine-grained structures impedes the movement of corrosive agents, thus reducing the likelihood of corrosion. In conclusion, the grain structure of aluminum sheet has a significant impact on its properties. Fine-grained structures generally enhance strength, ductility, hardness, and corrosion resistance, while coarse-grained structures tend to have the opposite effects. Therefore, it is crucial to control and optimize the grain structure during the manufacturing process in order to achieve the desired properties of aluminum sheet for different applications.

- Q: Which are better? I currently have steel (kinda ugly) rims on my Chevy Blazer right now, and my roommate has some aluminum alloy rims that will fit that he wants to sell me. He hates my steel rims so much that he's willing to sell me the alloy ones for $100.Should I take it? Or just stick with my steel ones?

- Aluminum rims are a whole lot better on the mechanical stand point, they are lighter, usually stronger (depending on the alloy) and they allow for better heat disapation. Lighter rims will save gas money (nothing you will notice, maybe an extra mile/tank, if that). Depending on the alloy used in the aluminum rims, they are usually stronger and can take more froce abuse, just as long as they don't get scuffed up, ect. With the better heat disapation. When the brakes heat up, the heat is sent out ever direction, mostly through metal. Aluminum (alloy) is a great conductor of heat. So when the brakes heat up, the aluminum rims will absord much of this heat, and the outside air will be able to cool the rim faster then the brakes themselves, but the brakes will stay cooler this way. Brakes that are running cooler, will last longer then brakes running hot. You will have less of a chance of brake fade a condition where the brakes get to a point of being to hot, they don't function at all, or its hard to stop the vehicle. It will also extend the brakes over all life, in some cases up to 40-50%. I had stock steel rims in my truck, small rims for a small truck, and whenever I was doing highway driving, i would get brake fade under high speed braking. When I switched to aluminum rims, I have not had brake fade since, I don't know about the life on the pads, as I switched the rims, before I wore a set down. I picked up a set of 4 5spoke rims from an Explorer and put them on my ranger, I paid $80 for the 4 and they look in pretty good shape, little corrosion. A down side to aluminum rims is corrosion, they corrode easier, and can cuase discolouration of the rim itself, or can cause leaky tires if it corrodes around the bead seat, which it usually does. Its a fair trade off however.

- Q: 8mm which type of aluminum plate is suitable for bending?

- What is your bending angle?If only bending is required, the quality of the aluminum sheet is of little concern.First of all, the state is the most important, the state is divided into hard, semi hard, soft (usually soft called O state)(1) the bending effect of the whole hard is not too far (the aluminum plate is H18, H19, H38 and so on are all hard)(2) the aluminum sheet in the semi hard state can be basically bent (H24, that is, semi hard)(3) the bending of the O state is certainly not a problem, but as a result of being too soft, there is little bending in this stateSecond, you have to choose pure aluminum or alloy aluminum?Pure aluminum hardness is not very good, with 1100, 1050, 1060 and so on can be recommended 1100 H26Alloy aluminum hardness is better, can use 3003, 3005, 5052 and other semi hard state can be.

- Q: What are the potential safety issues that may arise from the use of aluminum sheets?

- <p>Aluminum sheets are generally safe to use in most applications. However, there are a few safety concerns to consider. First, aluminum can be a skin irritant for some individuals, so it's important to wear protective gloves when handling. Second, aluminum dust, when inhaled, can cause respiratory issues. Proper ventilation should be maintained during cutting or grinding operations. Lastly, aluminum can conduct electricity, so it should not be used in electrical applications without proper insulation. Always follow safety guidelines and use protective equipment when working with aluminum sheets to minimize these risks.</p>

- Q: Can aluminum sheets be used in aerospace industry?

- Yes, aluminum sheets can be used in the aerospace industry. Aluminum is a commonly used material due to its lightweight properties, high strength-to-weight ratio, and excellent corrosion resistance. It is used in various components of aircraft such as wings, fuselage, and structural parts.

- Q: This question asks about the ability of aluminum sheets to withstand weather conditions without deteriorating.

- <p>Aluminum sheets have excellent weathering resistance. They are highly resistant to corrosion and oxidation, which makes them suitable for outdoor applications. Aluminum forms a protective oxide layer when exposed to air, which prevents further corrosion. This property allows aluminum sheets to maintain their appearance and structural integrity over time, even in harsh weather conditions. Additionally, aluminum can be coated or anodized to further enhance its resistance to weathering.</p>

- Q: What is the corrosion resistance of aluminum sheets?

- Aluminum sheets have excellent corrosion resistance. Aluminum naturally forms a protective oxide layer on its surface when exposed to oxygen, which acts as a barrier against corrosion. This oxide layer is very stable and prevents further oxidation of the metal, making aluminum highly resistant to corrosion in most environments. Additionally, aluminum sheets can be further enhanced with surface treatments or coatings to increase their corrosion resistance even more. This makes aluminum sheets a popular choice for various applications where corrosion resistance is crucial, such as in the construction industry, automotive manufacturing, and marine applications.

Send your message to us

Aluminum Corrugated Sheets for Cookware and Lighting Cover

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords