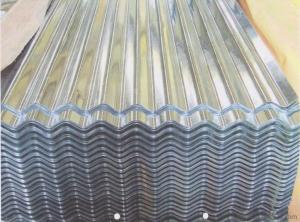

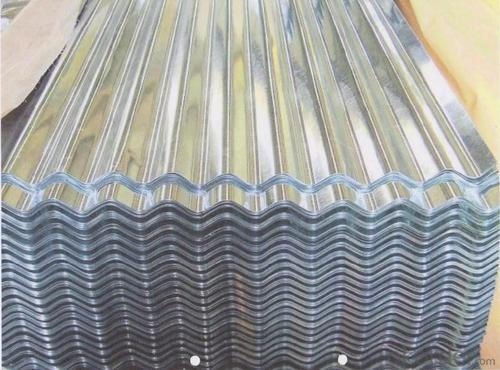

Aluminum Corrugated Sheet for Any Application

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium alloys with a wide range of properties are used in engineering structures. Alloy systems are classified by a number system (ANSI) or by names indicating their main alloying constituents (DIN and ISO).

The strength and durability of aluminium alloys vary widely, not only as a result of the components of the specific alloy, but also as a result of heat treatments and manufacturing processes. A lack of knowledge of these aspects has from time to time led to improperly designed structures and gained aluminium a bad reputation.

One important structural limitation of aluminium alloys is their fatigue strength. Unlike steels, aluminium alloys have no well-defined fatigue limit, meaning that fatigue failure eventually occurs, under even very small cyclic loadings. This implies that engineers must assess these loads and design for a fixed life rather than an infinite life.

Another important property of aluminium alloys is their sensitivity to heat. Workshop procedures involving heating are complicated by the fact that aluminium, unlike steel, melts without first glowing red. Forming operations where a blow torch is used therefore require some expertise, since no visual signs reveal how close the material is to melting. Aluminium alloys, like all structural alloys, also are subject to internal stresses following heating operations such as welding and casting. The problem with aluminium alloys in this regard is their low melting point, which make them more susceptible to distortions from thermally induced stress relief. Controlled stress relief can be done during manufacturing by heat-treating the parts in an oven, followed by gradual cooling—in effect annealing the stresses.

The low melting point of aluminium alloys has not precluded their use in rocketry; even for use in constructing combustion chambers where gases can reach 3500 K. The Agena upper stage engine used a regeneratively cooled aluminium design for some parts of the nozzle, including the thermally critical throat region.

Another alloy of some value is aluminium bronze (Cu-Al alloy).

Aluminium foil acts as a total barrier to light and oxygen (which cause fats to oxidise or become rancid), odours and flavours, moistness, and germs, it is used broadly in food and pharmaceutical packaging. The purpose of aluminium is to make long-life packs (aseptic processing|aseptic packaging) for drinks and dairy goods, which allows storing without refrigeration. Aluminium foil containers and trays are used to bake pies and to pack takeaway meals, ready snacks and long life pet foods.

Aluminium foil is widely sold into the consumer market, often in rolls of 500 mm (20 in) width and several metres in length.It is used for wrapping food in order to preserve it, for example, when storing leftover food in a refrigerator (where it serves the additional purpose of preventing odour exchange), when taking sandwiches on a journey, or when selling some kinds of take-away or fast food. Tex-Mex restaurants in the United States, for example, typically provide take-away burritos wrapped in aluminium foil.

Aluminium foils thicker than 25 μm (1 mil) are impermeable to oxygen and water. Foils thinner than this become slightly permeable due to minute pinholes caused by the production process.

- Q: I would have contacted you by email but your preferences aren't set to allow it.The Performance Corsa did indeed have a lugged aluminum frameIf you look closely each joint has a pop rivet that held the thing together as the epoxy hardenedThis was one of the UEC factory first forays into aluminumThe lugs and tubes were post treated prior to assembly.Those pop rivets never did give me a warm fuzzy feeling even when the bikes were newI still vote for recycling the frame into beer cans (or whatever they make out of aluminum frames).

- One step ahead of youI just couldn't get comfortable riding it Despite all the answers to my question saying it was fine I decided to trust my gutNow my old bridgestone gets another chance at life sporting numerous upgrades to its stock equipmentI saw those rivets and that was one of the reason I decided not to use itI could even see the glue bonding the seat stays to the seat tubeI'm not familiar with aluminum frames of any age so I don't know if this is normal Thank for the heads up though I really appreciate it

- Q: What characteristics of aluminum strips make them ideal for specific uses?

- <p>Aluminum strips are suitable for certain applications due to their lightweight nature, high strength-to-weight ratio, and excellent corrosion resistance. They are also known for their good thermal and electrical conductivity, making them ideal for heat sinks and electrical components. Additionally, aluminum strips are easily machinable and can be formed into various shapes, which is beneficial for manufacturing. Their non-magnetic properties are advantageous in applications where magnetic interference is a concern. Lastly, aluminum's recyclability and cost-effectiveness make it an environmentally friendly and economical choice for many industrial applications.</p>

- Q: my dad lives in Alaska, and he has money in the freezer wraped in aluminum foil He's had it there for 11 yearsWill that hurt the money?

- If the money is 11 years old, it's possible he could have some money that's worth something more than face valueIf he has any money that are star notes and low serial numbers, they could be valuableRemember that money changed over at about 1999 to the new style, so he has the old style money from approx1995 seriesHere's what kind of serial you are looking for should you guys go through it: 00002691 (star at the end of the serial number) or 00666600 (unique serial number)The stars with low serial are the most valuableWater damage is an issue with the notes! That will decrease the value, so you better figure out the best way to thaw the notes without damaging themRip them, bend the corners, fold them down the center.you are ticking off valueOh and I didn't see that anyone said that money is not paper.it's actually mostly cotton, so it's not like it's going to ruin the money.

- Q: 0.6mm insulation aluminum coil price insulation aluminum coil where to buy the most assured?

- If the surface of the aluminum color, it is directly on the Internet search color coated aluminum roll can be. Best site inspection, and now more factories, quality uneven

- Q: I made a cheesecake in a pan I've used numerous times, and the bottom of the oven got quot;greasy,quot; evidently from the buttery graham cracker crustThe kitchen smelled like burned grease! It was a disaster!

- If the pan is prone to leaking, after testing it by filling the pan with water before using, then wrap the outside (bottom and sides) of the springform pan with two layers of aluminum foil to prevent any leaking.

- Q: How do aluminum coils contribute to sustainable and green building practices?

- Aluminum coils play a crucial role in sustainable and green building practices due to their numerous environmental benefits. Here's how aluminum coils contribute to these practices: 1. Energy efficiency: Aluminum coils are lightweight and have excellent thermal conductivity, making them ideal for insulation purposes. When used as a part of the building's envelope, aluminum coils help reduce heat transfer, resulting in increased energy efficiency. This, in turn, reduces the need for excessive heating or cooling, leading to lower energy consumption and greenhouse gas emissions. 2. Longevity and durability: Aluminum is highly resistant to corrosion and has a longer lifespan compared to other materials. This durability reduces the need for frequent replacements, which can have a significant environmental impact. By using aluminum coils in construction, we can reduce waste and conserve resources. 3. Recyclability: Aluminum is one of the most recyclable materials available, with a high recycling rate. When aluminum coils reach the end of their life cycle, they can be easily recycled and turned into new products without any loss in quality. By choosing aluminum coils, we support a closed-loop recycling system, reducing the demand for virgin materials and minimizing waste. 4. Reduced carbon footprint: Aluminum production requires significantly less energy compared to other metals like steel or copper. This lower energy consumption results in a reduced carbon footprint during the manufacturing process. Additionally, using recycled aluminum in coil production requires even less energy, making it an even more sustainable choice. 5. Reflectivity: Aluminum has high reflectivity, allowing it to reflect sunlight and heat away from the building. This property helps reduce cooling loads, especially in hot climates, thereby reducing the energy needed for air conditioning. By incorporating aluminum coils in roofing or cladding, buildings can minimize their impact on local microclimates and reduce the urban heat island effect. Overall, aluminum coils contribute to sustainable and green building practices by promoting energy efficiency, durability, recyclability, and reducing the carbon footprint. By choosing aluminum as a construction material, we can create greener buildings that conserve resources, reduce waste, and minimize environmental impact.

- Q: Indicate which of the following is an element, compound, heterogeneous mixture, or solution:aocean water bcalciumcvitamin Cddry iceegrain alcoholfafter-shaveghamburgerhaluminum foilimilkjiron nail

- This is not a good start to your chemistry class if you are stuck with the easy questionsHow about reading the chapter?

- Q: I bought my wife aluminum siding for her anniversary presentWill she be impressed? The package is huge.?

- When are men going to realize that bigger is not betterI hope it was at least wrapped in a nice big ribbonThere was a time in my marriage when I actually appreciated gifts like thisI remember getting 2 x 12 foot rough planking for fencingI was thrilledOr the time I received several tons of gravel for our drivewayI was being an appreciative wife and those gifts kept me in shapeStill didn't do any goodHe found greener pastures anywaysSo girls, go for the good stuffNice vacations, bling bling (if that is your cup of tea, not mine) sexy nighties perhaps? She might be more grateful that you realize.

- Q: I was thinking of throwing them on the grill first to make them crisp then wrapping them in foil and throw in crockpot for few hours to get that fall over the bone tendernessfeedback?

- Some of my son's friends got together and made T shirts with iron on letters, they all thought of something funny to say and made lots of shirtsThese were 19 year old girls.

- Q: I found and purchased an antique car collection for my father for ChristmasIt has small, individual cars grooved into 1-inch silver chunksIt needs to be cleaned before I give it to himBut I'm afraid I'll damage itHave any solutions? Thanks in advance!

- You should become an authorYes, you should be worried about your imaginary friendHe could be suffering from imnotrealandthisisatrollingquestionphobi.

Send your message to us

Aluminum Corrugated Sheet for Any Application

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords