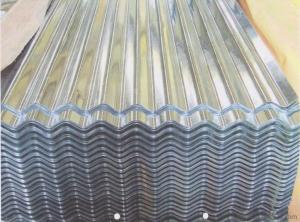

Aluminum Corrugated Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium alloys with a wide range of properties are used in engineering structures. Alloy systems are classified by a number system (ANSI) or by names indicating their main alloying constituents (DIN and ISO).

The strength and durability of aluminium alloys vary widely, not only as a result of the components of the specific alloy, but also as a result of heat treatments and manufacturing processes. A lack of knowledge of these aspects has from time to time led to improperly designed structures and gained aluminium a bad reputation.

One important structural limitation of aluminium alloys is their fatigue strength. Unlike steels, aluminium alloys have no well-defined fatigue limit, meaning that fatigue failure eventually occurs, under even very small cyclic loadings. This implies that engineers must assess these loads and design for a fixed life rather than an infinite life.

Another important property of aluminium alloys is their sensitivity to heat. Workshop procedures involving heating are complicated by the fact that aluminium, unlike steel, melts without first glowing red. Forming operations where a blow torch is used therefore require some expertise, since no visual signs reveal how close the material is to melting. Aluminium alloys, like all structural alloys, also are subject to internal stresses following heating operations such as welding and casting. The problem with aluminium alloys in this regard is their low melting point, which make them more susceptible to distortions from thermally induced stress relief. Controlled stress relief can be done during manufacturing by heat-treating the parts in an oven, followed by gradual cooling—in effect annealing the stresses.

The low melting point of aluminium alloys has not precluded their use in rocketry; even for use in constructing combustion chambers where gases can reach 3500 K. The Agena upper stage engine used a regeneratively cooled aluminium design for some parts of the nozzle, including the thermally critical throat region.

Another alloy of some value is aluminium bronze (Cu-Al alloy).

Aluminium foil acts as a total barrier to light and oxygen (which cause fats to oxidise or become rancid), odours and flavours, moistness, and germs, it is used broadly in food and pharmaceutical packaging. The purpose of aluminium is to make long-life packs (aseptic processing|aseptic packaging) for drinks and dairy goods, which allows storing without refrigeration. Aluminium foil containers and trays are used to bake pies and to pack takeaway meals, ready snacks and long life pet foods.

Aluminium foil is widely sold into the consumer market, often in rolls of 500 mm (20 in) width and several metres in length.It is used for wrapping food in order to preserve it, for example, when storing leftover food in a refrigerator (where it serves the additional purpose of preventing odour exchange), when taking sandwiches on a journey, or when selling some kinds of take-away or fast food. Tex-Mex restaurants in the United States, for example, typically provide take-away burritos wrapped in aluminium foil.

Aluminium foils thicker than 25 μm (1 mil) are impermeable to oxygen and water. Foils thinner than this become slightly permeable due to minute pinholes caused by the production process.

- Q: Can aluminum coils be used in the production of aluminum foam panels?

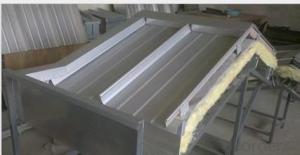

- Yes, aluminum coils can be used in the production of aluminum foam panels. Aluminum foam panels are typically made by injecting a foaming agent into molten aluminum, which causes the aluminum to expand and form a foam structure. This foam is then solidified and can be further processed into panels. Aluminum coils are commonly used in various industries, including construction, automotive, and packaging, due to their excellent properties such as lightweight, high strength, corrosion resistance, and thermal conductivity. These properties make aluminum coils suitable for use in the production of aluminum foam panels. To produce aluminum foam panels, the aluminum coil can be processed into a flat sheet or strip, which is then cut into the desired size and shape for the panels. The flat aluminum sheet or strip can be easily handled and processed during the foam production process. The foam-forming agent can be introduced into the molten aluminum, and the expanding aluminum foam can be poured onto the flat sheet or strip to form the panels. The use of aluminum coils in the production of aluminum foam panels allows for efficient manufacturing processes, as the coils can be easily rolled, shaped, and cut to meet specific design requirements. Additionally, the use of aluminum coils ensures that the foam panels maintain the desirable properties of aluminum, such as strength, durability, and light weight. Overall, aluminum coils can be effectively used in the production of aluminum foam panels, providing a versatile and cost-effective solution for various applications, including insulation, sound absorption, and structural components.

- Q: i need to put _ through a printer.?

- The foil question is interesting but impossibleThe surface has to be porous and absorb either ink or particulate toner (transferred through magnetics and heat)However, I do know that craft stores, like Michaels, sells foil sheet that are coated with something that allows them to be written onNever seen one that could be printed on, but I'd bet it would be possibleNow, for trying to shove wood through a printerNOYou need a surface with less textureThe uneven grain and fiber striations would interfere with the action of the print headMy recommendation is get yourself some transfer paper and print on thatThen do a rub on or heat transfer to the vennerGood luck.

- Q: How does the alloy composition affect the mechanical properties of aluminum sheet?

- The alloy composition of aluminum sheet plays a significant role in determining its mechanical properties. The inclusion of different elements in the alloy can influence its strength, hardness, ductility, and other characteristics. For instance, adding small amounts of copper or manganese can enhance the strength of aluminum, while magnesium can improve its corrosion resistance. Additionally, the size and distribution of alloying elements within the sheet can also impact its mechanical properties. Therefore, careful selection of alloy composition is crucial to achieve the desired mechanical performance of aluminum sheet.

- Q: How do you install cold air intake on a 97 Honda Civic DX?All I have is a black tube for my intake, I think.Adam

- Soundproofing Material

- Q: I have a pioneer DEH-P4800MP radio unit, it has a front panel that swings down and the panel obviously has all my controls and buttons on itTheres contacters that touch inside the flap and the actual inside front of the radio to send the signal from the buttons I push into the actual circuit boards inside the unit, the contacters are really touchy and barely ever make contact unless I lick my finger and put spit on them to get it to work until it driesTheres about 6 copper contact spots that touch, my question, is if it would fix it to put aluminum foil inside to cover all the contact spots, or do you think that would short something out because it would then make the all of the normally seperate contacters be going through the same current?

- Oktrust me this worksIt may not work on ur acrylic nails thoughits worth a try! ok so take ur clear coat and paint a think amount on the nailthen wait like 2 seconds and wipe offThe chemicals in the clear nail polish works as a removerIt works with real nails really well so i would try it on the acrylic nailsGood Luck!

- Q: What's the difference between a non-stick and hard anodized pans?

- Diet and exercise are necessary to lose and maintain weight loss, but diet is not just about counting calories and avoiding certain foodsIt is also about what foods that you add to your dietI found an inspiring web page that you might want to check out,

- Q: I have some black clip in extensions and I was wondering if I just brought some brown hair die and applies it will it become brownI am trying to get it to about 1b off black

- If you are a DIYer, many home centers will loan you an insulation blower for little to nothing if you buy the insulation from them.

- Q: What knives do you need for cutting aluminum 2A12 bars?

- Common machine tools using high-speed steel cutting tools are more common.

- Q: Easter eggs need freezing otherwise they loose shapeWhat could be done otherwise

- wellYou could fill a baking pan with iceput aluminum foil over thatThen the chocolate.

Send your message to us

Aluminum Corrugated Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords