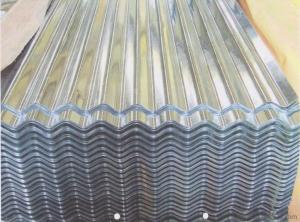

Teal Sheets Aluminum for Corrugated

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium alloys with a wide range of properties are used in engineering structures. Alloy systems are classified by a number system (ANSI) or by names indicating their main alloying constituents (DIN and ISO).

The strength and durability of aluminium alloys vary widely, not only as a result of the components of the specific alloy, but also as a result of heat treatments and manufacturing processes. A lack of knowledge of these aspects has from time to time led to improperly designed structures and gained aluminium a bad reputation.

One important structural limitation of aluminium alloys is their fatigue strength. Unlike steels, aluminium alloys have no well-defined fatigue limit, meaning that fatigue failure eventually occurs, under even very small cyclic loadings. This implies that engineers must assess these loads and design for a fixed life rather than an infinite life.

Another important property of aluminium alloys is their sensitivity to heat. Workshop procedures involving heating are complicated by the fact that aluminium, unlike steel, melts without first glowing red. Forming operations where a blow torch is used therefore require some expertise, since no visual signs reveal how close the material is to melting. Aluminium alloys, like all structural alloys, also are subject to internal stresses following heating operations such as welding and casting. The problem with aluminium alloys in this regard is their low melting point, which make them more susceptible to distortions from thermally induced stress relief. Controlled stress relief can be done during manufacturing by heat-treating the parts in an oven, followed by gradual cooling—in effect annealing the stresses.

The low melting point of aluminium alloys has not precluded their use in rocketry; even for use in constructing combustion chambers where gases can reach 3500 K. The Agena upper stage engine used a regeneratively cooled aluminium design for some parts of the nozzle, including the thermally critical throat region.

Another alloy of some value is aluminium bronze (Cu-Al alloy).

Aluminium foil acts as a total barrier to light and oxygen (which cause fats to oxidise or become rancid), odours and flavours, moistness, and germs, it is used broadly in food and pharmaceutical packaging. The purpose of aluminium is to make long-life packs (aseptic processing|aseptic packaging) for drinks and dairy goods, which allows storing without refrigeration. Aluminium foil containers and trays are used to bake pies and to pack takeaway meals, ready snacks and long life pet foods.

Aluminium foil is widely sold into the consumer market, often in rolls of 500 mm (20 in) width and several metres in length.It is used for wrapping food in order to preserve it, for example, when storing leftover food in a refrigerator (where it serves the additional purpose of preventing odour exchange), when taking sandwiches on a journey, or when selling some kinds of take-away or fast food. Tex-Mex restaurants in the United States, for example, typically provide take-away burritos wrapped in aluminium foil.

Aluminium foils thicker than 25 μm (1 mil) are impermeable to oxygen and water. Foils thinner than this become slightly permeable due to minute pinholes caused by the production process.

- Q: Hi everyone, I have this problem that I'm somewhat confused about. The problem is:An alloy of aluminum and magensium was treated with sodium hydroxide solution, in which only aluminum reacts to give hydrogen gas:2Al + 2NaOH + 6H20 --gt; 2NaAl(OH)4 + 3H2If a sample of alloy weighing 1.118 g gave 0.1068 g of hydrogen, what is the percentage aluminum in the alloy?How do I account for the magnesium and what stoichiometric relationships would I need to set-up? This is very confusing, but I appreciate the slightest of help on this!Thank you.

- You don't need to worry about the magnesium at all, because it doesn't enter into the reaction. You have a balanced equation for aluminium and hydrogen, and the data given are sufficient: From the equation, you know that 2 moles of aluminium produce 3 moles of H2. 0.1068 g of H2 were produced, so divide this by molecular mass of H2 (2.016) to determine the moles of H2 produced. You know that 3 moles of H2 would have been produced from 2 moles of Al. Therefore, multiply the moles of H2 by 2/3, to determine the moles of Al that were present. Now multiply this number by the atomic mass of Al, to determine the grams of Al. Now divide this number if grams by 1.118 and multiply by 100 to determine % Al present in the alloy.

- Q: What are the dimensions of 101 aluminum sheets?

- The dimensions of 101 aluminum sheets can vary depending on the specific requirements and specifications of the sheets.

- Q: I'm working on a costume that's entirely made of cardboard (it's a giant robot), and I was wondering What's the best way to1 turn Soda cans into aluminum sheeting2: attach the aluminum everywhere on the robot3. Attach the aluminum to the aluminumThank you in advance.

- You are going to hate this answer: because the answer is: It depends. Without further details of what you are trying to accomplish its hard to know. 1: For instance if you are just trying to get small sheets of aluminum...cut off the top and bottom with scissors and one straight line down the middle. But if you are looking for something more accurate you may need to use a press or just buy sheets 2: Again, without knowing details its hard to say...perhaps you should use ducktap and layer the aluminium onto the cardboard like scale armor 3: you could use glue I guess....or do a weak weld...or if you scaled the aluminum then you wouldn't ahve to connect the aluminum to itself only to the cardboard. But it all depends on how quality you want the project to look...and what you want the end product to look like. But since you are talking about cardboard and cans I'm guessing scaling the aluminum with duck tape should work for you.

- Q: Are aluminum sheets suitable for aerospace structural components?

- Yes, aluminum sheets are suitable for aerospace structural components. Aluminum is a lightweight and durable material that has been widely used in the aerospace industry for many years. It possesses excellent strength-to-weight ratio, making it highly desirable for various applications in aircraft manufacturing. Aluminum sheets offer several advantages for aerospace structural components. Firstly, they are lightweight, which helps reduce the overall weight of the aircraft. This is crucial for improving fuel efficiency, increasing payload capacity, and enhancing the performance of the aircraft. Additionally, the lightweight nature of aluminum sheets allows for easier handling and assembly during the manufacturing process. Secondly, aluminum has excellent corrosion resistance properties. This is crucial for aerospace applications as the components are exposed to various environmental conditions, such as high humidity, extreme temperatures, and exposure to chemicals. The corrosion resistance of aluminum ensures the longevity and durability of the structural components, reducing the need for frequent maintenance and replacement. Furthermore, aluminum is a highly malleable material, allowing for easy shaping and forming into complex structures. It can be easily bent, cut, and fabricated to meet specific design requirements, making it versatile for various aerospace applications. The ability to form complex shapes with aluminum sheets enables engineers to design efficient and streamlined structures, optimizing aerodynamics and minimizing drag. Another advantage of aluminum sheets is their excellent thermal conductivity. This property allows for efficient heat dissipation, which is crucial in aerospace applications where components may be exposed to high temperatures generated during flight or engine operation. The thermal conductivity of aluminum helps prevent overheating and ensures the structural integrity of the components. In conclusion, aluminum sheets are highly suitable for aerospace structural components due to their lightweight, corrosion resistance, malleability, and thermal conductivity properties. These characteristics make aluminum an ideal material for various applications in the aerospace industry, contributing to the overall performance, efficiency, and safety of aircraft.

- Q: Can aluminum sheet be used for architectural applications?

- Yes, aluminum sheet can be used for architectural applications. It is a versatile material that offers durability, lightweight properties, and corrosion resistance, making it suitable for various architectural projects such as facades, roofing, window frames, and decorative elements. Additionally, aluminum can be easily formed, fabricated, and finished to meet specific design requirements, making it a popular choice in the construction industry.

- Q: And isn't aluminum extremely bad for ones health?

- it's okorder

- Q: Are aluminum sheets suitable for architectural applications?

- Yes, aluminum sheets are suitable for architectural applications. Aluminum is a versatile material that offers numerous advantages for architectural projects. It is lightweight, yet strong, making it easy to handle and install. Its corrosion-resistant properties make it well-suited for outdoor applications where it is exposed to the elements. Aluminum sheets can be easily formed into various shapes and sizes, allowing for creative and innovative architectural designs. They can be used for cladding, roofing, facades, and interior applications such as ceilings, partitions, and decorative elements. Additionally, aluminum sheets are available in a wide range of finishes, including anodized, painted, or coated, providing architects with the freedom to choose the desired aesthetic for their projects. These finishes can enhance the durability and color retention of the material, ensuring long-term performance and minimal maintenance requirements. Moreover, aluminum is a sustainable material as it is fully recyclable and has a low carbon footprint compared to other metals. This aligns with the increasing focus on environmentally-friendly construction practices in the architectural industry. In summary, aluminum sheets are highly suitable for architectural applications due to their lightweight, strength, corrosion resistance, versatility, range of finishes, and sustainable attributes. Architects can confidently choose aluminum sheets to create visually appealing and durable structures.

- Q: Which is good, aluminum curtain wall?

- Aluminum veneer manufacturers preferred Beijing Jinsheng Aluminium Industry Co. Ltd., it is very important to choose a single aluminum plate manufacturers, Beijing Jinsheng Aluminium Industry Co. Ltd is a professional manufacturer of aluminum veneer, advanced CNC equipment, first-class fluorocarbon spraying line, is your trusted manufacturer of aluminum veneer, aluminum veneer of large manufacturers, advanced technology, advanced technology and to undertake all types of single aluminum plate engineering, quality assurance, price concessions.

- Q: Can aluminum sheets be used for elevator interiors?

- Yes, aluminum sheets can be used for elevator interiors. Aluminum is a popular material choice for elevator interiors due to its various advantageous properties. It is lightweight, durable, and resistant to corrosion, making it suitable for long-term use in elevator applications. Aluminum sheets can be easily fabricated and shaped to fit the dimensions and design requirements of elevator interiors. Additionally, aluminum can be finished with different types of coatings or finishes, such as anodizing or powder coating, to enhance its appearance and provide additional protection. Overall, aluminum sheets are a viable option for elevator interiors and are commonly used in the industry.

- Q: What is the thickness range available for aluminum sheets?

- The thickness range available for aluminum sheets typically varies from 0.006 inches (0.15mm) to 0.25 inches (6.35mm), depending on the specific requirements and application.

Send your message to us

Teal Sheets Aluminum for Corrugated

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords