1/2 Inch Wide Aluminum Strips for Aluminium Metal Roofing Sheet for Steel Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

He conducted a similar experiment in 1827 by mixing anhydrous aluminium chloride with potassium and yielded aluminium.[63] Wöhler is generally credited with isolating aluminium (Latin alumen, alum). Further, Pierre Berthierdiscovered aluminium in bauxite ore.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

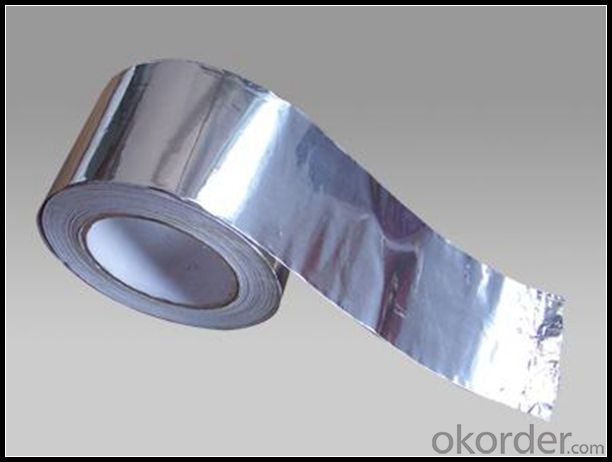

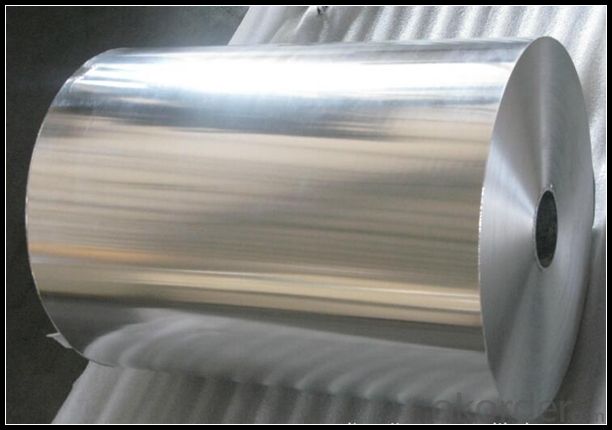

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: Is it possible to join aluminum strips together through welding?

- <p>Yes, aluminum strips can be welded. Welding aluminum requires specific techniques and equipment due to its high thermal conductivity and reactivity. Common methods include gas tungsten arc welding (GTAW), also known as TIG welding, and gas metal arc welding (GMAW), or MIG welding. These processes involve using a filler material and an inert shielding gas to prevent oxidation. Proper preparation, such as cleaning the aluminum surface and controlling the heat input, is crucial for a successful weld.</p>

- Q: How to use batteries, magnets, cans of aluminum belt to make a rotating aluminum belt device, please explain

- On the left is an aluminum can top. It is on a vertical shaft and can rotate freely. On the right is a used water pen holder, the same on the vertical shaft, you can freely rotate.

- Q: Is it possible to utilize aluminum strips in a construction project focused on sustainability and environmental responsibility?

- <p>Yes, you can use aluminum strips for a green building project. Aluminum is a versatile and sustainable material due to its recyclability and low energy consumption in production. It also has a high strength-to-weight ratio, which can contribute to the energy efficiency of a building. However, it's important to consider the source of the aluminum and ensure it is produced with minimal environmental impact. Using recycled aluminum can further enhance the green credentials of your project.</p>

- Q: This question asks about potential dangers associated with using aluminum strips in a residential setting.

- <p>Using aluminum strips in a home can pose several safety issues. Firstly, aluminum is a good conductor of electricity, so if it comes into contact with live electrical wires, it can cause short circuits or even electrocution. Secondly, aluminum strips can be sharp and may cause cuts or injuries if handled improperly. Additionally, aluminum dust can be harmful if inhaled, potentially causing respiratory issues. Lastly, in the event of a fire, aluminum can melt and release toxic fumes, posing a significant health risk. It's crucial to handle aluminum strips with care and ensure they are used in a safe manner, away from electrical sources and in a well-ventilated area.</p>

- Q: This question asks for an overview of the various types of aluminum strips that are available in the market.

- <p>Aluminum strips are available in various types based on their thickness, width, alloy composition, and surface finish. Common types include: 1) Plain aluminum strips, which are general-purpose and used in packaging and construction. 2) Embossed aluminum strips, used for decorative purposes or to enhance grip. 3) Anodized aluminum strips, which offer improved corrosion resistance and are used in automotive and aerospace applications. 4) Heat-treated aluminum strips, which have enhanced strength and are used in structural components. 5) Coated aluminum strips, which have a protective or decorative layer applied, used in food packaging and electronics. 6) Foil strips, which are very thin and used in food packaging, pharmaceuticals, and thermal insulation. Each type has specific applications and properties that make it suitable for particular industries and uses.</p>

- Q: What types of aluminum strips are better suited for specific uses?

- <p>Yes, different types of aluminum strips are more suitable for specific applications based on their properties. For instance, 1100 series aluminum strips are pure and have excellent formability, making them ideal for deep drawing applications. 3003 series strips are commonly used for chemical equipment, shipbuilding, and aircraft structures due to their good corrosion resistance and weldability. 5052 series strips are known for their high strength and are often used in marine applications and transportation vehicles. 6061 series strips are popular for structural applications requiring strength and good corrosion resistance, such as in the construction and automotive industries. The choice of aluminum strip depends on the specific requirements of the application, including strength, formability, corrosion resistance, and environmental factors.</p>

- Q: Is it possible to utilize recycled aluminum in a project as an alternative to new raw materials?

- <p>Yes, you can use recycled aluminum in your project instead of new raw materials. Recycled aluminum is not only more environmentally friendly but also often more cost-effective. It requires significantly less energy to produce compared to new aluminum, reducing carbon emissions. Additionally, using recycled aluminum can help conserve natural resources and reduce waste in landfills. However, it's important to consider the quality and purity of the recycled material to ensure it meets the specifications required for your project.</p>

- Q: What are the regular maintenance tasks required for aluminum strips?

- <p>Regular maintenance tasks for aluminum strips primarily involve cleaning and inspection. It's essential to remove dirt and debris to prevent corrosion and maintain the strip's integrity. Periodic visual inspections should be conducted to check for any signs of wear, damage, or corrosion. If the aluminum strip is part of a mechanical system, lubrication may be necessary to reduce friction and wear. Additionally, ensuring that the strip is securely fastened and not under undue stress is crucial. For outdoor applications, regular checks for environmental damage are advised. In some cases, protective coatings or treatments may be applied to extend the strip's lifespan.</p>

- Q: Is it possible to use aluminum strips as a material for exterior wall cladding?

- <p>Yes, aluminum strips can be used for exterior cladding. They are known for their durability, resistance to corrosion, and low maintenance requirements. Aluminum cladding is lightweight, which makes it easier to install compared to heavier materials. It also offers excellent weather resistance and can be painted or finished in various ways to enhance the appearance of a building. Additionally, aluminum is a sustainable choice as it can be recycled, contributing to environmental sustainability.</p>

- Q: The user is asking if it's possible to use aluminum strips in the construction of solar panels.

- <p>While aluminum is a common material used in the construction of solar panels, particularly for framing and mounting, it is not used to create the actual solar cells. Solar cells are typically made from silicon, which is capable of converting sunlight into electricity. Aluminum strips can be used in the assembly and support structure of solar panels, but they do not contribute to the photovoltaic effect that generates electricity. Therefore, you cannot use aluminum strips to make the active solar cell component of solar panels.</p>

Send your message to us

1/2 Inch Wide Aluminum Strips for Aluminium Metal Roofing Sheet for Steel Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords