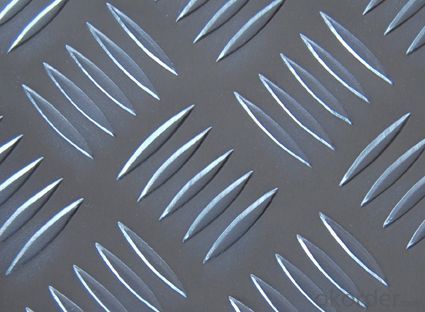

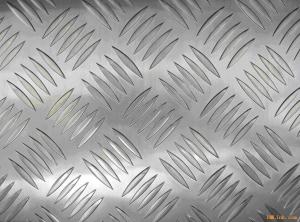

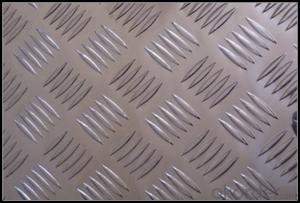

Aluminum Sheets for Sale 06 - Al Sheet Five Bars

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible light and an excellent reflector (asmuch as 98%) of medium and far infrared radiation. The yield strengthof pure aluminium is 7–11 MPa, while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffness of steel.It is easily machined, cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spellingdifferences) are alloysin which aluminium(Al) is the predominant metal. The typical alloying elements are copper, magnesium,manganese,silicon,tin and zinc. There are twoprincipal classifications, namely casting alloys and wrought alloys, both of which are furthersubdivided into the categories heat-treatableand non-heat-treatable. About 85% of aluminium is used for wrought products,for example rolled plate, foils and extrusions.Cast aluminium alloys yield cost-effective products due to the low meltingpoint, although they generally have lower tensile strengthsthan wrought alloys. The most important cast aluminium alloy system is Al–Si,where the high levels of silicon (4.0–13%) contribute to give good castingcharacteristics. Aluminium alloys are widely used in engineering structures andcomponents where light weight or corrosion resistance is required

Secification:

Finishing:Mill Finish, Painted, One Side Bright, Brushed and Coil Anodizing available onrequest

Alloy: AA1050, 1060, 1100, AA3003, 3005, 3015, 5052, 5754,5083,8011, etc

Temper:H14/16/18/22/24/32,HO etc.

Thickness: 0.2mm—100mm

Width: 100mm—2300mm(Can be slitted)

Standard:GB/T 3880-2006 ASTM B-209

Features:

1. Excellent quality of products

2. Quick delivery

3. Best service to clients

4. BV,SGS avalible

5. No buckle o waveness

6. Tension leveling

7. Certificate of Origin

8. Form A,E

Packaging Detail: Carton ,Wooden pallet with plastic protection packing,standard seaworthy packing or as your request.

ProductionCapacity:

AnnualProduction capacity of 600,000 tons.

Products areexported to United States, Canada, U.A.E, Brazil, Mexico,Thailand, Vietnam,Nigeria etc, over 100 countries andregions all over the world.

Coveredfactories with full production line

CNBM aluminumproduction base is comprised of 18 aluminumannealers, 10 coil and foilmills, 4 continuous production lines, 2hot rolling production line and 3prepainted lines.

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shanghai port

4. Delivery time?

30 day after client’s deposit

- Q: This question asks for methods to verify the quality of aluminum sheets before purchasing them.

- <p>To ensure the quality of aluminum sheets, first, check for certifications such as ISO or ASTM standards. Inspect the surface for any defects like scratches, dents, or unevenness. The color should be uniform and the edges should be smooth. Request a sample and perform a bend test to check for flexibility and strength. Ensure the thickness is consistent as specified. Look for a reputable supplier with good customer reviews. Lastly, consider the price; if it's too low, it might indicate compromised quality.</p>

- Q: What is the coefficient of thermal expansion of aluminum sheets?

- The coefficient of thermal expansion of aluminum sheets varies depending on the specific alloy used. However, on average, aluminum has a coefficient of thermal expansion of approximately 22 x 10^-6 per degree Celsius (22 x 10^-6/°C). This means that for every degree increase in temperature, the aluminum sheet will expand by 22 x 10^-6 times its original size. It is important to note that this value may slightly differ for different grades and alloys of aluminum.

- Q: What specific conditions or criteria need to be met when installing aluminum windows to ensure they are properly fitted and functional?

- <p>When installing aluminum windows, there are several special requirements to consider: ensuring the frames are level and square, using the correct size and type of fasteners, applying a proper sealant to prevent air and water infiltration, and adhering to local building codes. Additionally, it's crucial to check for thermal insulation properties, especially in areas with extreme weather conditions. The installation should also allow for proper drainage to prevent water damage. Professional installation is often recommended to meet these requirements and ensure the windows function correctly and last longer.</p>

- Q: Can aluminum sheet be used for architectural applications?

- Aluminum sheet is indeed suitable for architectural purposes, thanks to its impressive strength, durability, and resistance to corrosion. It is widely utilized in the construction field for various architectural applications such as cladding, roofing, and facades. Architects and designers can select aluminum sheets in different thicknesses to meet their specific aesthetic and functional requirements. These sheets can be easily shaped, bent, and formed to create distinctive architectural elements like panels, screens, louvers, and decorative features. Moreover, aluminum sheets can be coated or finished to enhance their appearance and protect them from environmental factors. Techniques such as anodizing, powder coating, or painting can be employed to improve the material's resilience against weathering, UV radiation, and pollution. Due to its lightweight nature, aluminum is favored for architectural applications as it reduces the overall weight of the structure and facilitates convenient installation. Additionally, aluminum is an environmentally friendly option for architectural projects as it can be recycled infinitely, thus promoting sustainability. To summarize, aluminum sheets are a highly viable and popular choice for architectural purposes because of their strength, versatility, durability, and aesthetic appeal.

- Q: You are probably think wtf. Lol, so I just got a Mac and I HATE its keyboard! Also, I have been looking at Fallout 3, and I think its looks amazing! Here is my question: Should I get the new aluminum keyboard for my Mac or Fallout 3? I have $60 to spend and I have found a place to get one or the other for under $60. I could also get on Ebay and get BOTH! Which one/option should I do?

- Have you used the Apple Aluminum keyboard before? Most people either love it or hate it. The low-profile keys feel a lot different than a traditional keyboard. Personally, I like it and can type faster on the AL, but I know a lot of people that got rid of it and got a different keyboard. You don't NEED to use an Apple keyboard on your Mac - you can use any USB keyboard you want. So you COULD get a cheaper alternate keyboard and still get Fallout as well. Windows keyboards don't have the same quick pick button across the top as an Apple keyboard, but you can custom configure your keyboard commands in System Profile-Keyboard Mouse-Keyboard Shortcuts (under the Apple logo at the top-left of your screen) and set whatever keys or key combos to do those missing commands. But I don't think Fallout 3 is out for Mac, is it? I couldn't find a version with a quick Google search.........a Windows version won't run on your Mac unless you have Windows installed with either Boot Camp (included in OS X 10 Leopard) or with a virtual PC like VMWare Fusion or Parallels. Unless you are running Windows on your Mac (like I am) don't waste your money on a PC game you won't be able to play. Enjoy your new Mac!

- Q: 1. Esrp for aluminum is -1.66V. Why is Al not reactive when dipped in cold water?2. Explain why the reaction between water and Al becomes more reactive when Al has been treated first with Mercury chloride.3. Aluminum hydroxide dissolve in both acid and base. What do you call this type of behavior?4. Describe the function of aluminum hydroxide in the testile industry.5. Aluminum sol. which contains [Al(H2O)6]3+ ions have the tendency to hydrolyze. Why? Recommend a method to prevent hydrolysis of aluminum ions.6. In the preparation of alum, sulphuric acid is added to the aluminum hydroxide sol. Why?

- Al is not reactive because it is so reactive - it gets coated with oxide immediately on exposure, the oxide layer is strong and quite inert except to strong acids.

- Q: The diameter of a hole drilled through aluminum at 22°C is 7.50 mm. Find the diameter and the area of the hole at 89°C.

- If i was once you, i might depart a small 1cm gap on the high and cover it with mesh - these round ones don't appear to allow a lot air flow in any respect in my viv and i have three... I have a tendency to simply leave the glass open a bit of at both aspect. You'll have got to use a great mesh although to stop bugs escaping via it. BTW - i think you will have to make it slightly deeper... 1.5 at least in case you are maintaining reps a good way to grow to 12inch plus.

- Q: I am looking at buying a used 1983-84 Eldorado but have read some things about the reliability of the aluminum engine. Any thoughts? Thanks.

- 1984 Cadillac Eldorado

- Q: What are the safety concerns to be aware of when handling aluminum sheets?

- <p>When working with aluminum sheets, there are a few safety concerns to consider. First, aluminum dust can be a respiratory hazard, so it's important to use proper ventilation and personal protective equipment like masks. Second, sharp edges can cause cuts; always handle aluminum sheets with gloves and proper tools. Additionally, aluminum is a good conductor of electricity, so avoid contact with live electrical wires. Lastly, when cutting or shaping aluminum, eye protection is crucial due to the risk of flying debris. Always follow safety guidelines specific to your workplace and the tools you are using.</p>

- Q: The furnace above is only hot enough to melt lead, but isn't hot enough to melt aluminum. I'm not looking for a blowtorch, or something too expensive or could melt gold, but just something that i can buy and is like the one above but isn't that expensive and can melt aluminum. Thanks!

- Aluminum melts below 1300F These gold and silver melters like the one in the link go to 2000F or more and should work for aluminum. I guess more small melters of metals want to melt gold and silver than aluminum.

Send your message to us

Aluminum Sheets for Sale 06 - Al Sheet Five Bars

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords