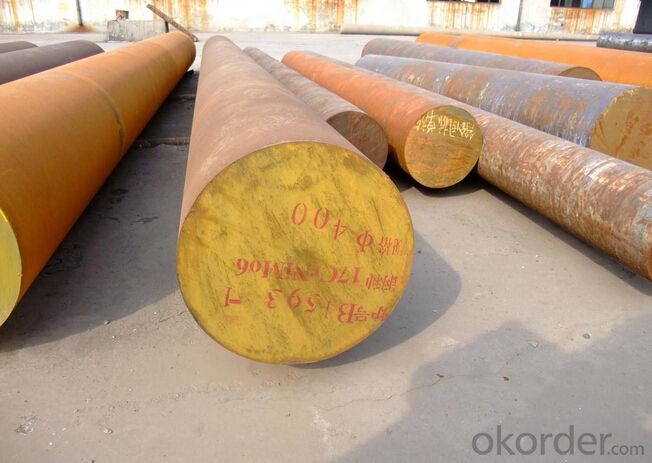

Alloy Steel 5crnimov/1.2714 Tool Steel Special Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Chemical Composition%(GB)

| C | Si | Mn | Ni | Cr | Mo |

| 0.49-0.54 | 0.2-0.3 | 0.95-1.05 | 1.95-2.10 | 0.95-1.10 | 0.45-0.55 |

Characterstics

| 1.High toughness and strength | |||||||

| 2.Higher abrasion resistance | |||||||

| 3.Remaining hardness of HB300 at 500℃ | |||||||

| 4.Insensitive to tempering brittleness due to addition of Mo |

Applications: Suitable for large and medium sized forging dies with thickness of 250-350mm for automobiles,tractors,transmission gears,front axle beams and rear axles of automobiles,and forging dies for engineering machine components

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

4, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

We provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: How does special steel perform in cryogenic ductility?

- Special steel exhibits excellent performance in terms of cryogenic ductility. Cryogenic ductility refers to a material's ability to retain its strength and flexibility even at extremely low temperatures. Special steels are engineered specifically to endure harsh conditions, including cryogenic temperatures, making them suitable for applications such as LNG storage tanks, aerospace components, and superconductors. The composition of special steel is one of the key reasons for its exceptional cryogenic ductility. Generally, special steels are alloyed with elements like nickel, chromium, and molybdenum, which enhance their mechanical properties and resistance to low temperatures. These alloying elements provide the steel with increased strength, toughness, and resistance to brittle fracture, even in extremely cold environments. Moreover, special steels go through rigorous testing and quality control measures to ensure their performance in cryogenic conditions. This involves testing for parameters such as impact toughness, fracture toughness, and notch toughness, which are critical in assessing a material's ability to withstand brittle failure at low temperatures. Additionally, the manufacturing processes employed for special steel contribute to its excellent cryogenic ductility. Methods like vacuum induction melting and controlled cooling are often utilized to produce special steels. These techniques aid in eliminating impurities and improving the material's microstructure. This refined microstructure enhances the steel's ductility, enabling it to retain its mechanical properties even in cryogenic temperatures. In conclusion, special steel exhibits exceptional performance in terms of cryogenic ductility due to its meticulously designed composition, stringent testing, and advanced manufacturing processes. These factors make it a dependable and preferred choice for various industries that require materials capable of withstanding extreme cold conditions while maintaining strength and flexibility.

- Q: How does special steel contribute to the durability of products?

- Special steel contributes to the durability of products due to its unique properties and composition. It is designed to have increased strength, hardness, and resistance to wear and corrosion, making it suitable for demanding applications. Special steel enhances the structural integrity and longevity of products, ensuring they can withstand heavy loads, extreme temperatures, and harsh environments without compromising performance or safety.

- Q: What are the main applications of special steel in the power distribution industry?

- Special steel is widely used in the power distribution industry for various applications. One of the main applications is in the construction of transmission towers and electrical pylons. Special steel is preferred for these structures due to its high strength, durability, and resistance to corrosion. It ensures the safe and reliable transmission of electricity over long distances. Special steel is also used in the manufacturing of electrical transformers and generators. The steel's magnetic properties make it suitable for creating efficient and reliable power generation and distribution equipment. Additionally, special steel is used in the production of electrical connectors and conductors, which are essential for ensuring the efficient flow of electricity through power distribution systems. Overall, the main applications of special steel in the power distribution industry include transmission towers, electrical pylons, transformers, generators, and electrical connectors. These applications play a crucial role in maintaining a robust and reliable power grid, ensuring uninterrupted electricity supply to consumers.

- Q: How does special steel perform in electrical conductivity applications?

- Special steel, which is also known as stainless steel, offers exceptional electrical conductivity properties in a wide range of applications. It finds extensive use in electrical engineering and electronics owing to its high resistance against corrosion and low electrical resistance. By incorporating specific alloys like chromium and nickel, its conductivity is further enhanced, making it the ideal option for efficient electricity conduction. Within electrical conductivity applications, special steel demonstrates low resistivity, enabling the seamless flow of electrical current with minimal energy loss. Its low resistance plays a vital role in minimizing heat generation, which is crucial for preventing overheating and ensuring the efficient functioning of electrical components. Special steel also possesses outstanding magnetic properties, making it a suitable choice for applications that demand both electrical conductivity and magnetic strength. This attribute proves particularly beneficial in the production of transformers, motors, and generators. Furthermore, special steel boasts exceptional durability and the ability to withstand harsh environmental conditions, making it well-suited for outdoor applications. Its corrosion resistance prevents the formation of rust, ensuring a long lifespan and consistent performance even in challenging environments. In conclusion, special steel is an excellent material for electrical conductivity applications due to its low electrical resistance, high corrosion resistance, and exceptional durability. Its unique properties make it the preferred choice in various industries that rely on efficient and dependable electrical conductivity.

- Q: How does special steel perform in high-velocity impact conditions?

- Special steel is specifically designed to provide exceptional performance in high-velocity impact conditions. Its unique composition and metallurgical properties make it highly resistant to deformation and failure when subjected to extreme forces. One of the key characteristics of special steel is its high strength, which allows it to withstand the tremendous forces experienced in high-velocity impact situations. This strength is a result of careful alloying and heat treatment processes that enhance the material's ability to absorb and distribute energy. As a result, special steel can effectively resist deformation and maintain its structural integrity even under severe impact loads. Additionally, special steel possesses excellent toughness, enabling it to absorb large amounts of energy before fracturing. This property is crucial in high-velocity impact conditions, where the material needs to withstand sudden and intense forces. The high toughness of special steel allows it to absorb and dissipate the impact energy, preventing catastrophic failure and ensuring the continued performance of the component or structure. Moreover, special steel often exhibits excellent wear and abrasion resistance, which is beneficial in high-velocity impact scenarios that involve sliding or rubbing contact. This resistance to wear ensures that the material retains its integrity and functionality even under prolonged and repetitive impact conditions, reducing the risk of premature failure. In summary, special steel performs exceptionally well in high-velocity impact conditions due to its high strength, excellent toughness, and superior wear resistance. Its ability to withstand extreme forces and absorb impact energy effectively makes it a preferred choice for applications where durability and reliability are paramount.

- Q: Can special steel be used for making surgical instruments?

- Yes, special steel can be used for making surgical instruments. Special steel, also known as surgical steel or medical-grade steel, is specifically designed to meet the high standards required for medical and surgical applications. It is highly resistant to corrosion, has excellent strength and durability, and can withstand repeated sterilization processes without losing its properties. Surgical instruments made from special steel are known for their precision, reliability, and ability to maintain a sharp cutting edge. These instruments are essential in various surgical procedures, including but not limited to, cutting, dissecting, manipulating, and suturing tissues. The use of special steel ensures that surgical instruments are safe, hygienic, and suitable for use in medical environments.

- Q: What are the main applications of special steel in the semiconductor industry?

- Special steel is widely used in the semiconductor industry for various applications. One of the main applications is in the production of wafer fabrication equipment, such as vacuum chambers, deposition tools, and etching systems. The high strength, corrosion resistance, and thermal stability of special steel make it suitable for these critical components that operate under extreme conditions. Additionally, it is also used in the manufacturing of precision molds and dies required for semiconductor packaging processes. Overall, special steel plays a vital role in ensuring the reliability, performance, and quality of semiconductor manufacturing processes.

- Q: Is special steel suitable for electrical and electronic applications?

- Yes, special steel is suitable for electrical and electronic applications. Special steel is often used in electrical and electronic applications due to its excellent conductivity, high strength, and resistance to corrosion and wear. It is commonly utilized in the manufacturing of electrical connectors, circuit breakers, transformers, and various other components in the electrical and electronic industry.

- Q: How does special steel perform in terms of electrical conductivity?

- Special steel generally has low electrical conductivity compared to other metals such as copper or aluminum. This is due to the high carbon content and other alloying elements present in special steel, which impede the flow of electric current. However, certain types of special steel, such as stainless steel, can exhibit better electrical conductivity when compared to regular carbon steel.

- Q: How does special steel perform in heat treatment applications?

- Special steel performs well in heat treatment applications due to its unique composition and properties. It has a high carbon content, which allows it to be hardened and tempered to achieve desired hardness, strength, and wear resistance. The controlled heating and cooling processes during heat treatment enable the transformation of its microstructure, enhancing its mechanical properties. Special steel also exhibits excellent heat resistance, maintaining its strength and toughness even at elevated temperatures. Overall, special steel is highly suitable for heat treatment applications, providing superior performance and durability.

Send your message to us

Alloy Steel 5crnimov/1.2714 Tool Steel Special Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords