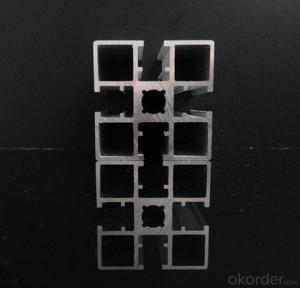

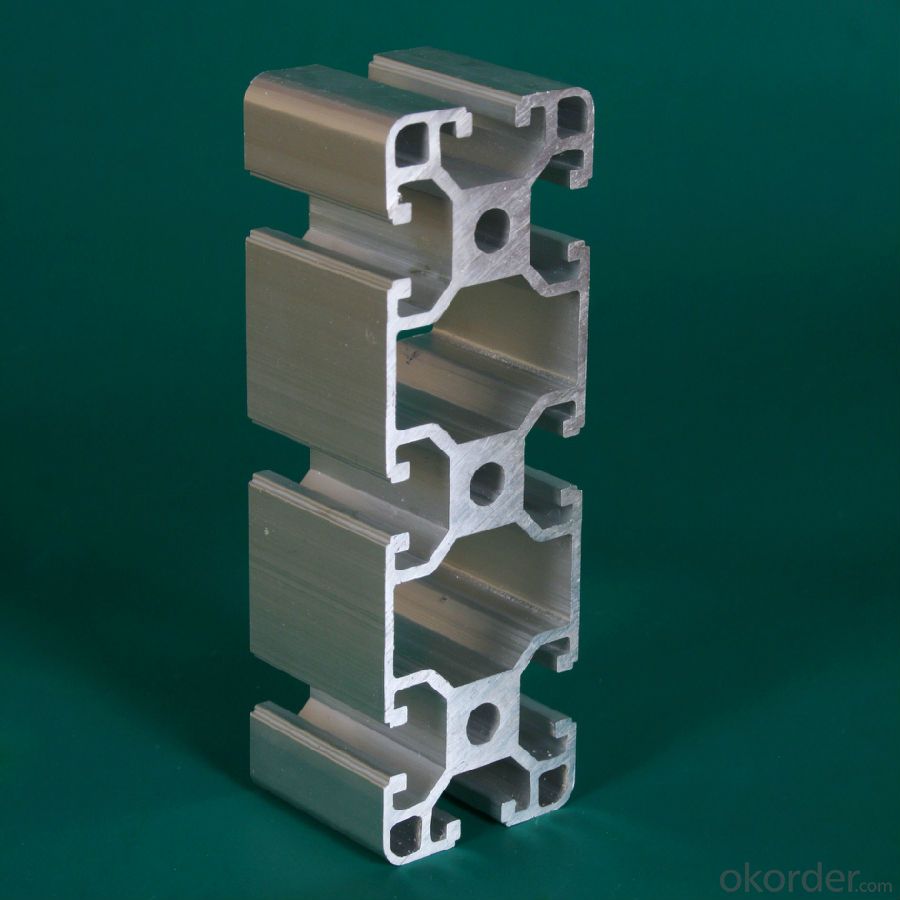

Aluminum Track Profiles - Alloy 6005 Aluminium Extrusion Profiles for Industrial Application

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Product Name | Alloy 6005 Aluminium Extrusion Profiles For Industrial Application |

Alloy | Al 6063 T5 /T6 or 6061 T4/T6 or as customers' need |

Surface | Aluminum profiles of mill finish, powder coating, anodizing, polishing, sand blasting, electrophoresis and wood color. |

Profile shape | According to drawings or re-design as requested or market needs. |

Price | Based on Aluminum Ingot Price + Process fee |

Payment term | T/C T/T 30% deposit and 70% pay against copy of B/L |

Certificate | ISO9001 ISO14001 |

Warranty | 1. GB5237-2008 equal to EN12020-1.2(2001); 2. Within 15 years without powder peeling off; |

Product Advantages

1. Plenty of surface treatments for your choice, for example oxidation, electrophoresis and static powder coating, etc.

2. Strict control for surface finish, very little scratch.

3. Accurate mold as well as accurate size.

4. Standard alloy composition

5. Both ends of the profiles are very plain and with no burr.

FAQ

1. What is your main product?

We can supply the aluminium complete system, including aluminum billets, aluminum profile for windows and doors, aluminum for curtain wall, alumimun framwork, and kinds of aluminum windows and doors.

2. What’s your price?

The price is based on buyer's specific requirement, so please provide below information to help us quote exact price to you.

3. What is your payment term?

30% - 50% down payment, the balance payment against, and L/C is available.

- Q: This question asks for a method to determine whether the building materials include aluminum profiles.

- <p>To determine if your current building uses aluminum profiles, you can start by examining the visible structural components such as window frames, door frames, and support beams. Look for the characteristic silvery color and smooth finish of aluminum. You can also check the building's documentation or blueprints, if available, for material specifications. Consulting with the building's architect or engineer can provide definitive information. In some cases, a non-destructive testing method like ultrasonic testing might be used to identify materials without damaging the structure.</p>

- Q: Are aluminum profiles suitable for use in roofing systems in areas with high wind conditions?

- <p>Yes, aluminum profiles can be used for roofing systems in windy regions. Aluminum is a lightweight and durable material that can withstand high winds. It is often used in the construction of roofing systems because of its strength and resistance to corrosion. Additionally, aluminum profiles can be designed to meet specific wind load requirements, making them suitable for areas prone to strong winds. However, the design and installation of the roofing system must be done correctly to ensure it can handle the wind forces.</p>

- Q: Can aluminum profiles be used for outdoor applications?

- Outdoor applications can indeed utilize aluminum profiles. Aluminum, known for its versatility and durability, is resistant to corrosion, making it a suitable material for outdoor environments. Its exceptional weather resistance allows it to endure exposure to sunlight, rain, and temperature fluctuations without degradation. In various fields like construction, architecture, transportation, and outdoor furniture, aluminum profiles are frequently employed due to their strength, stability, and longevity, making them a favored option for outdoor projects. Moreover, protective coatings or anodizing can be applied to aluminum profiles to enhance their resistance to the elements commonly found outdoors.

- Q: Are aluminum profiles suitable for use in sustainable or eco-friendly construction projects?

- <p>Yes, aluminum profiles can be used for green building projects. They are valued for their recyclability, which contributes to sustainability. Aluminum is lightweight, strong, and requires less energy to produce and transport compared to other materials like steel. Additionally, aluminum's durability can lead to a longer lifespan, reducing the need for frequent replacements and thus minimizing waste. Moreover, aluminum can be used in energy-efficient designs, such as in window frames that provide better insulation, further enhancing the green credentials of a building.</p>

- Q: Can aluminum profiles be used in lighting fixture manufacturing?

- Yes, aluminum profiles can be used in lighting fixture manufacturing. Aluminum is a commonly used material in the lighting industry due to its various beneficial properties. It is lightweight, durable, and corrosion-resistant, making it ideal for outdoor and indoor lighting fixtures. Aluminum profiles can be easily shaped and manipulated to create various designs and forms, allowing for creative and innovative lighting solutions. Additionally, aluminum profiles can be coated or anodized to enhance their aesthetic appeal and provide additional protection against wear and tear. Overall, aluminum profiles are a popular choice in lighting fixture manufacturing due to their versatility, functionality, and aesthetic appeal.

- Q: Can aluminum profiles be used for transportation applications?

- Yes, aluminum profiles can be used for transportation applications. Aluminum is a lightweight and durable material that offers high strength-to-weight ratio, corrosion resistance, and versatility. These qualities make it suitable for various transportation applications such as aircraft, automobiles, trains, ships, and even bicycles. Aluminum profiles are commonly used in the construction of vehicle bodies, frames, panels, and other structural components, helping to reduce weight and enhance fuel efficiency.

- Q: Explain the various uses of aluminum profiles in architectural design.

- <p>Aluminum profiles have a wide range of applications in architectural design due to their strength, durability, and versatility. They are commonly used for curtain walls, which provide a sleek and modern appearance while offering thermal insulation. Aluminum profiles are also used in window and door frames for their lightweight and strong properties, enhancing security and energy efficiency. They are integral in the construction of sun shading systems and louvers, which help control light and heat in buildings. Additionally, aluminum profiles are used in structural components like beams and columns, as well as in decorative elements such as facades and balustrades, offering both functional and aesthetic benefits.</p>

- Q: Can aluminum profiles be used in the construction industry?

- The construction industry can utilize aluminum profiles, which possess qualities such as being lightweight, durable, and resistant to corrosion. These attributes make them suitable for a wide range of construction applications. Aluminum profiles are commonly employed in the production of windows, doors, curtain walls, and structural framing systems. They offer an excellent strength-to-weight ratio, enabling the creation of large and intricate structures without excessive weight. Furthermore, they are easily molded into various shapes and sizes, providing flexibility in design and construction. The thermal conductivity of aluminum profiles is also advantageous, as it allows for efficient insulation and energy conservation. All in all, due to their versatility, durability, and aesthetic appeal, aluminum profiles are a favored choice in the construction industry.

- Q: What is the nitriding process of aluminum extrusion die?

- Nitriding process:The main process parameters of gas nitrocarburizing are nitriding temperature, nitriding time, and nitriding atmosphere.The gas soft nitriding temperature is usually 560-570 DEG C, because the nitrided layer has the highest hardness at this temperature. The nitriding time is usually 3-4 hours, because the hardness of the compound layer reaches the maximum at 2-3 hours after penetration, while the depth of the nitrided layer increases slowly with time. The nitriding atmosphere is determined by the rate of ammonia decomposition and the rate of dripping of the carbonaceous penetrant.

- Q: Are aluminum profiles suitable for use in furniture fittings and accessories?

- Yes, aluminum profiles are indeed suitable for use in furniture fittings and accessories. Aluminum is a versatile material that offers several advantages for furniture applications. Firstly, aluminum profiles are lightweight, making them easy to handle and install. This is particularly beneficial for furniture fittings and accessories that may require frequent adjustments or movements. Additionally, aluminum profiles are highly durable and resistant to corrosion, ensuring a long lifespan for furniture fittings and accessories. This makes them suitable for both indoor and outdoor furniture, as they can withstand various environmental conditions without deteriorating. Aluminum is also highly customizable, allowing for a wide range of design options. It can be easily shaped, cut, and welded into various forms and sizes, enabling furniture designers to create unique and aesthetically pleasing fittings and accessories. Moreover, aluminum profiles are low-maintenance and easy to clean, making them ideal for furniture applications. They can be easily wiped down or washed without the risk of damage or degradation. Furthermore, aluminum is a sustainable and environmentally friendly material. It is 100% recyclable, meaning that it can be reused indefinitely without losing its properties. Using aluminum profiles in furniture fittings and accessories contributes to a more sustainable and eco-friendly design approach. Overall, the combination of lightweight, durability, customization options, low-maintenance, and sustainability makes aluminum profiles a suitable choice for use in furniture fittings and accessories. They offer numerous benefits and can enhance the functionality, aesthetics, and longevity of furniture pieces.

Send your message to us

Aluminum Track Profiles - Alloy 6005 Aluminium Extrusion Profiles for Industrial Application

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords