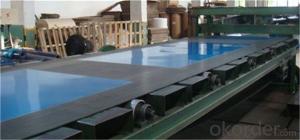

Alloy 1050 1060 1070 1100 Insulation Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Name | High Quality 3mm Thick Mill Finish Alloy 1050 1060 1070 1100 Insulation Aluminum Sheet Price Per Square Meter |

Material | Aluminum |

Other Material | 1060, 1050, 1070, 1100 |

Standard | ASTM, SUS, DIN etc |

Surface | Hairline ,oxidation ,mirror ,embossed ,etc |

Thickness | 0.15mm-2.0mm ,2.0mm-6mm ,6mm-25mm |

Width | 500mm,1000mm,220mm, 250mm,1500mm,or be custmer required |

Length | 1000mm,2000mm,2440mm,3000mm,3048mm,6000mm, or as customer required |

Application | 1. Lighting Accessories, Solar reflector plate ,Architectural appearance 2. Interior decoration: ceiling, metope, furniture, cabinets and so on 3. Elevator, Track , Ship, Medical equipment etc 4. Automotive interior and exterior decoration 5. Household appliances, refrigerator, microwave oven, audio equipment, etc. 6. Aerospace and military aspects, such as China'scurrent large aircraft, spacecraft series, satellite, etc. 7.Machinery parts processing, mold manufacturing 8.Chemical/insulation pipeline coating |

Payment Term | L/C , D/A , D/P , T/T , West Union , Money Gram , other |

Price Term | FOB, CIF, CFR , CNF etc |

Package | Export standard package:bundled wooden box or be required; |

Delievery Time | 1~ 2 days for sample; 15 ~ 40 days for production |

Loading Port | TianJing |

Supply Ability | 50000 t per month |

Why we choose Okorder.com?

Okorder.com is a professional and reliable online E-market place

Providing a variety of products with reasonable prices

High quality goods provided by factory suppliers

Shipping to over 200 countries.

One-stop sourcing

Dubai Logistic Complex

Okorder Quality Control?

We hold a very strict quality control system to check every connector of our products for your safety.

Okorder services for you

1.7*24 hours Hotline & Email Service

2. Your inquiry related to our products or prices will be replied in 24hrs.

3. Well-trained and experienced staffs to answer all your enquires in fluent English

4. OEM&ODM, any your customized demand we can help you to design and put into product.

5. Distributor ship are offered for your unique design and some our current models

- Q: I'm 17 and it has been very hard finding a deodorant that makes me stop sweating. I told my dad I wanted to get Ban or Mitchum cause the percentage of Aluminum is very high. He said the Aluminum in deodorant has links to alzheimers, is that true? Also my sister said I could just scrub with soap morning and night, use regular deodorant without antipersperant and that would make me stop sweating too. But since i'm a teenager and my hormones are still weird would that be strong enough to stop sweat?

- aluminum oxide in antipersperant does lead to alzheimer's, yes. but antiperspirant is not deodorant, and deodorant does not contain aluminum. sweating is a natural bodily function. if you need to sweat, sweat. it's odor that should bother people.

- Q: What are the different methods of surface patterning aluminum sheets?

- Aluminum sheets can be patterned using a variety of methods, each with its own benefits and applications. Some commonly used techniques include: 1. Mechanical Etching: By employing abrasive materials like sandpaper or wire brushes, patterns can be created on the aluminum surface. Different pressures and movements can be applied to achieve desired designs. Mechanical etching is a versatile and cost-effective method suitable for both simple and complex patterns. 2. Chemical Etching: Also known as chemical milling, this method involves using chemicals to selectively remove material from the aluminum surface and form patterns. The aluminum sheet is coated with a resist and then submerged in an etchant solution, which dissolves the exposed areas, leaving behind the desired pattern. Chemical etching allows for precise and intricate designs but requires careful control of the etching process. 3. Laser Engraving: This technique utilizes a high-power laser beam to remove material from the aluminum surface and create patterns. The laser beam is controlled by computer software, enabling precise and detailed designs. Laser engraving is suitable for both small and large-scale production, offering high accuracy and repeatability. 4. Embossing: In this method, the aluminum sheet is pressed between two dies with raised patterns, resulting in a three-dimensional design on the surface. Embossing can be achieved through mechanical or hydraulic presses and is commonly used to add texture and aesthetic appeal to aluminum sheets, such as for decorative purposes or branding. 5. Printing: Various printing techniques can be employed to apply patterns onto aluminum sheets. These include screen printing, which involves forcing ink through a mesh screen onto the aluminum surface, and digital printing, which utilizes inkjet technology for high-resolution patterns. Printing methods allow for a wide range of colors and designs, making them suitable for decorative applications. The choice of surface patterning method depends on factors such as desired pattern complexity, production volume, cost considerations, and the intended end-use of the aluminum sheets. Each method offers distinct advantages and limitations, allowing manufacturers to select the most suitable technique according to their specific requirements.

- Q: What are the dimensions and thickness options for aluminum sheets?

- Depending on specific requirements and applications, the dimensions and thickness options for aluminum sheets can vary. There is a wide range of sizes and thicknesses available to cater to different needs. Concerning dimensions, aluminum sheets come in various widths and lengths, typically ranging from 36 inches to 72 inches in width and 96 inches to 144 inches in length. However, these dimensions may vary depending on the supplier and the specific product. The thickness options for aluminum sheets also differ. Thickness is usually measured in gauge, where lower gauge numbers indicate thicker sheets. Aluminum sheets can be obtained in various gauges, ranging from 0.006 inches (very thin) to 0.5 inches (thicker) or even thicker for specialized applications. It is important to note that the specific dimensions and thickness options may vary depending on the supplier and the grade of aluminum being used. It is always advisable to consult with a supplier or manufacturer to obtain precise information about the available dimensions and thickness options for aluminum sheets.

- Q: This question asks for a comparison between aluminum sheets and other roofing materials, highlighting their differences.

- <p>Aluminum sheets differ from other roofing materials such as asphalt shingles, clay tiles, and metal roofs in several ways. They are lightweight, durable, and resistant to corrosion, making them ideal for coastal areas. Aluminum sheets offer a sleek, modern aesthetic and can be easily recycled, contributing to their environmental friendliness. Unlike asphalt shingles, which have a shorter lifespan, aluminum sheets are long-lasting and can withstand extreme weather conditions. They also don't require the same level of maintenance as clay tiles, which can crack over time. While metal roofs can be similar to aluminum in terms of durability, aluminum sheets are typically more cost-effective and offer a wider range of colors and finishes.</p>

- Q: does aluminum sheet has a function of magnetism isolating?

- copper sheet is better.

- Q: Can aluminum sheets be used in marine environments?

- Yes, aluminum sheets can be used in marine environments. Aluminum is a commonly used material in marine applications due to its excellent corrosion resistance. It forms a protective oxide layer on its surface, which prevents further corrosion in the presence of saltwater or other corrosive elements found in marine environments. Aluminum sheets are lightweight, yet strong, making them ideal for a variety of marine structures such as boat hulls, decks, and superstructures. Additionally, aluminum is highly durable and has a long lifespan, further enhancing its suitability for marine applications.

- Q: Are 101 aluminum sheets suitable for automotive body panels?

- Yes, 101 aluminum sheets are suitable for automotive body panels.

- Q: Can aluminum sheet be used for architectural façade systems?

- Yes, aluminum sheet can be used for architectural façade systems. Aluminum is a versatile material that offers durability, lightweight properties, and ease of installation, making it suitable for constructing attractive and functional façades in various architectural designs.

- Q: What are the different types of surface treatments available for powder-coated aluminum sheets?

- Some different types of surface treatments available for powder-coated aluminum sheets include anodizing, chemical etching, mechanical polishing, and electroplating. Each treatment offers unique benefits and can enhance the appearance, durability, and corrosion resistance of the aluminum sheets.

- Q: Are the aluminum sheets available in different grades?

- Indeed, there are various grades of aluminum sheets obtainable. Aluminum is widely utilized in different sectors owing to its lightweight, resistance to corrosion, and impressive strength-to-weight ratio. To cater to diverse applications, distinct grades of aluminum sheets have been tailored. Among the frequently encountered grades are 1100, 3003, 5052, 6061, and 7075. Each grade possesses distinctive qualities and attributes, encompassing strength, formability, weldability, and machinability. The selection of a grade relies on factors like the intended purpose, environmental circumstances, and desired characteristics of the end product.

Send your message to us

Alloy 1050 1060 1070 1100 Insulation Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords