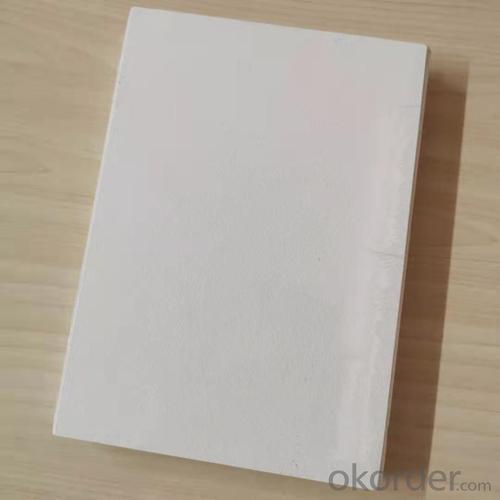

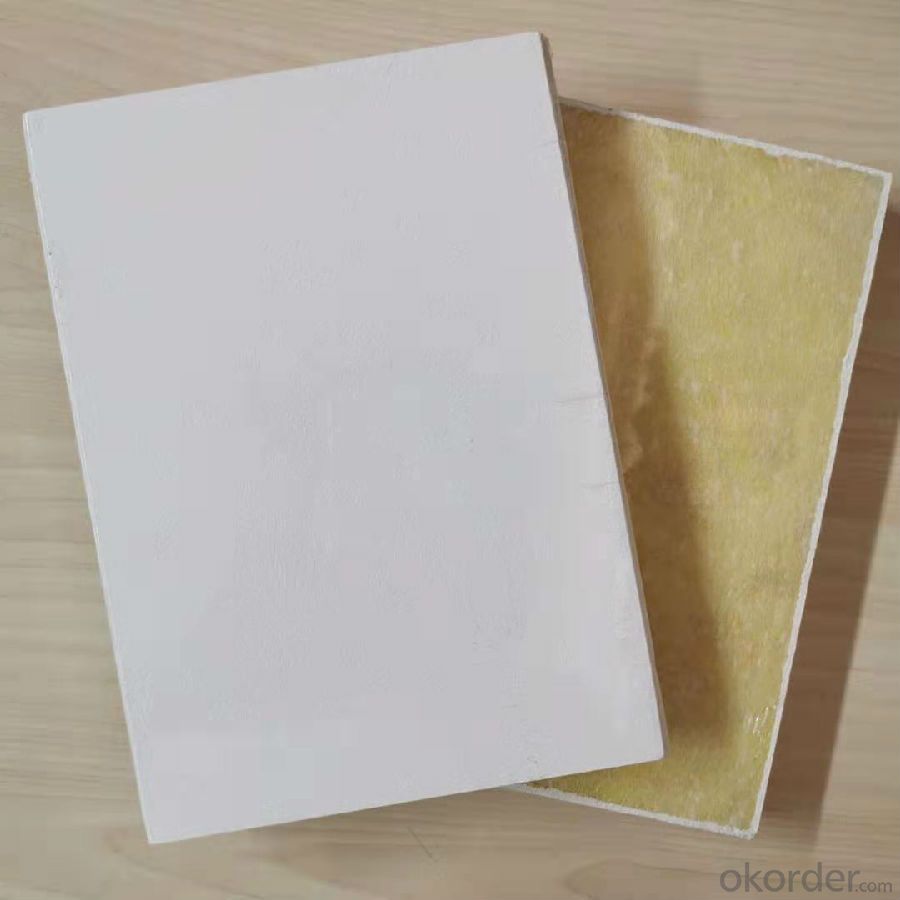

Glass Wool Ceiling Acoustic Suspended Ceiling Decorative Ceiling Tile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description

Fiberglass Acoustic Ceiling Tiles are great for use in both residential and commercial applications. It is an effective and affordable way to build sound absorbing acoustical ceilings with excellent sound absorption properties. They are effective in eliminating unwanted ceiling boundary reflections and controlling excessive room reverberation. They are widely applied in offices, restaurants, recording studios, theaters, cinemas, schools, garages, conference room, dance halls, etc.

Features

1. Excellent sound insulation.

2. Non-combustible, fire-proof.

3. Light weight and no sagging, wraapping or delaminationg.

4. Green eco-friendly building materials.

Application

It's recommended that this panels be installed to the opposite two walls to cntrol the echo of the surroundings.

The panels are widly used in hotels, meeting rooms, auditoriums, music rooms, libraried, etc, where have special requiest for sound absorption.

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 4 weeks after receiving of downpayment

Picture

- Q: My bathroom because of a variety of pipelines have been well, if the installation of tiles, then all the re-waste and then get, very troublesome! I would like to ask you there is no one can brush directly on the bathroom wall paint, asked to take a shower when the cold water will not fall in the above, hot water rushed in the above will not have any reaction. Have a friend please know please! Thank you!

- Bathroom waterproof two kinds of paint (1) synthetic polymer polyurethane waterproof coating (corner, etc. need to add polyester cloth, glass cloth, etc.) (2) polymer modified asphalt SBS waterproof coating (need to add carcass reinforcement polyester cloth, glass cloth, etc.).

- Q: Want to buy their own materials decoration, need to pay attention to what?

- Wire: the outer layer of thick insulation, fold a few, do not brittle white. Burn part of the skin, look inside the copper core thickness. Pay attention to distinguish between ordinary electrical appliances and high-power appliances with different lines. As for the brand each region has its own preferences, ask friends how much more neighbors to decorate.

- Q: What is the role of chemically tinned magnesium chloride?

- In the chemical industry is an important inorganic raw materials for the production of magnesium carbonate, magnesium hydroxide, magnesium oxide and other magnesium products, but also for the antifreeze and other raw materials. 2, in the metallurgical industry for the production of metal magnesium, liquid chlorine and high purity magnesia and so on. 3, in the building materials industry is the production of light building materials such as fiberglass, decorative panels, sanitary ware, ceilings, floor tiles, magnesium oxide cement, ventilation pipes, anti-theft covers, fire doors and windows, fire board, partition board, production of artificial marble High - rise building materials important raw materials. In the magnesite products can do high-quality magnesium tile, high-quality fire board, magnesium box, magnesium decoration plate, light wall panels, abrasive, stoves, fireworks and other additives. 4, in other areas can do food additives, protein coagulant, snow melting agent, refrigerant, dust, refractories and so on. With the brine (magnesium chloride aqueous solution) point of the tofu than the stone point of the tofu, soft and delicious 5. Metallurgical industry: used to manufacture refractory and puzzle arm of the adhesive, and is the manufacture of flux and smelting metal magnesium Of raw materials. 6. Machinery industry: life, with lime soil can be made of mechanical crates, triangular mats and furniture, etc., is "soil material" good material. 7. Transportation industry: for the road ice melting agent, ice fast, less corrosive to the vehicle, higher than the effect of sodium chloride. 8. Medicine: made of magnesium chloride "halogen dry" can be used for medicinal purposes. 9. Agriculture: available for magnesium fertilizer, potassium and magnesium fertilizer and cotton defoliants.

- Q: Waterproof acceptance how to accept kitchen and toilet waterproof is done?

- That white is off the water test is like to give you a basin, so you see it leak leak, is not broken, you have to go inside the basin with water inspection, but should pay attention to the length of the test, some things are not all of a sudden Can be seen, such as the house of leakage

- Q: How to decorate the living room

- Color and light - the layout of color and lighting is the main means of reflecting the artistic aesthetic and personality of the master. Color, should be the overall tone to be unified, do not use too much color, or will make the whole space is very messy. Note that the color decoration with soft decoration, which will produce your unexpected effect. Daytime living room to natural light-based, as far as possible to the natural light into the room; evening to artificial lighting, including decorative chandelier lighting, ceiling lamps, embedded lights and walls, such as mixed lighting, but to ensure that the room is bright Is still the first choice of lamps and lanterns, and then through the light to increase the level of space, contrast atmosphere.

- Q: What is the space body?

- In the humid environment, can also be used single or double perforated plate for the sound absorption layer (to increase the absorption of low frequency, perforation rate is generally less than 5%), instead of porous materials. ④ hanging pieces. Such as metal lugs, hooks, bolts and so on. When used, the surface are placed in the sound field, is conducive to give full play to the sound absorption of the material. The effective sound absorption area of ??a single sound absorber is much larger than the geometric projection area, so if the projection area is calculated, the sound absorption coefficient can be greater than one. The characteristic is usually expressed by the effective sound absorption, which depends not only on the nature of the body itself but also on the interval between the absorbers but not in a linear proportion. So the best design should be the use of the least sound absorber unit, get as much as possible sound absorption effect. It is generally believed that if the plate-like sound absorber is used, the total area is 30% -40% of the flat top area of ??the room, the sound absorption efficiency can reach the best value and the economic effect is the best. Space absorber is mainly used to reduce the reverberation time in the hall and factory workshop and the sound level of the reverberation field. It has many advantages such as flexible design, simple installation, convenient installation and beautiful appearance. But it should also be noted that only in the original indoor sound absorption is very small, reverberation field is very strong circumstances, and the noise reduction effect is usually not more than 10dB, generally between 3-8dB, the best will not exceed 15dB The

- Q: What are the decorative materials?

- Wallpaper, wall tiles, paint, paint, decorative panels, wall carpets, wood plywood, MDF, fire board wire water pipe cement and other hardware

- Q: How good is the Burton Hotel in Dubai?

- The only seven-star hotel in the world - Dubai, United Arab Emirates

- Q: I read that fiberglass insulation that has a backing sheet should have the backing sheet toward the heated space. The insulation in the basement ceiling has the backing sheet toward the inside of the basement not the bottom of the floor above. Does this trap moisture and cause a lot of harm or does it just make the insulation less effective? Do I need to take it all down and start with new insulation? Should I just add a new layer over the top what is there?

- you have the insulation installed correctly, the paper should be inside your room as you have described, they are referring to outside walls, it can now be sheet rocked or covered with some suitable covering. I have seen insulation without a paper barrier installed and there is no difference in the R- factor. Blown in insulation has no barrier, the paper is only on it for ease of handling and the company logo. don't worry at all and carry on.

- Q: Not sure how to spell something that sounds like "ah-spec-tice" please tell me where I can get into on aspectice.

- asbestos? Probably not, unless your house is really old. You probably have fiberglass insulation. Some old ceiling tiles maybe had asbestos, but not in recent years.

Send your message to us

Glass Wool Ceiling Acoustic Suspended Ceiling Decorative Ceiling Tile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords