5052 125 Mill Finish Aluminum Sheet 5xxx Series Alloy for Automotive Body

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminum Sheet 5XXX Series Alloy for Automotive Body

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Mill Finish Aluminum Sheet 5XXX Series Alloy for Automotive Body

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminum Sheet 5XXX Series Alloy for Automotive Body

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

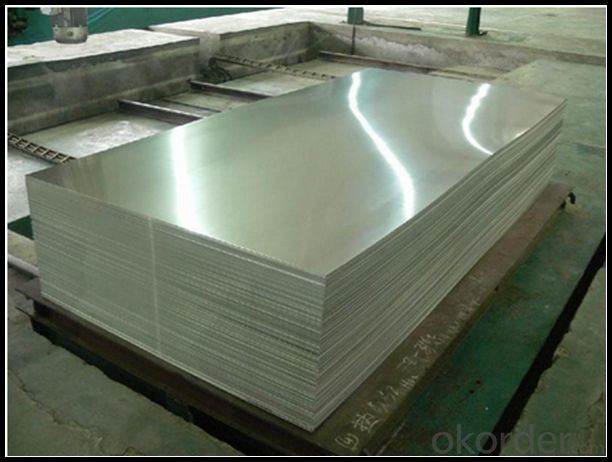

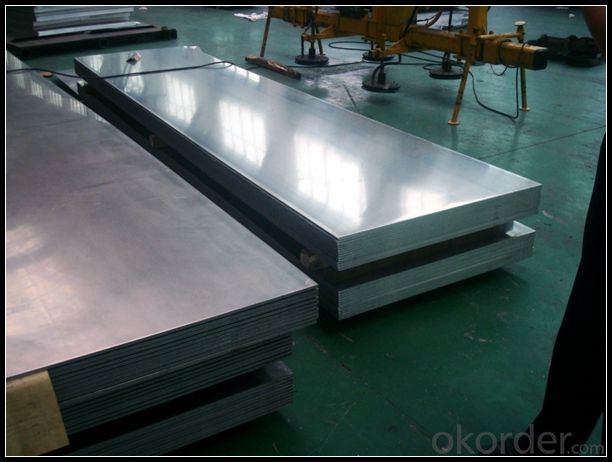

5. Image of Mill Finish Aluminum Sheet 5XXX Series Alloy for Automotive Body

6. Package and shipping of Embossed Aluminum Sheet AA1100 for Automotive Body

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum sheets suitable for use in food processing or packaging industries?

- Yes, aluminum sheets are suitable for use in food processing or packaging industries. Aluminum is a widely used material in the food industry due to its excellent properties such as being lightweight, corrosion-resistant, and having good thermal conductivity. It is also impermeable to moisture, oxygen, and light, which helps to preserve the quality and freshness of food products. Additionally, aluminum sheets can be easily formed into various shapes and sizes, making them versatile for different packaging requirements.

- Q: What are the different types of patterns available for aluminum sheets?

- Aluminum sheets come in a wide range of patterns, each with its own unique visual and functional appeal. Here are some popular patterns that you can find: 1. Diamond Pattern: This pattern features raised diamonds created by intersecting parallel lines at 60-degree angles. It offers excellent slip resistance and is commonly used for flooring, stairs, and walkways. 2. Stucco Pattern: The stucco pattern mimics the texture of traditional stucco plaster, with a pebble-like surface. It provides enhanced durability and is often used decoratively on walls, ceilings, and interior panels. 3. Hammered Pattern: The hammered pattern creates a rustic and artistic appearance with its dimpled texture. It is frequently used for decorative purposes, such as wall cladding or furniture accents. 4. Perforated Pattern: Perforated aluminum sheets have small holes that offer great ventilation and visibility. They are commonly used in architectural applications like facades, sunscreens, and noise barriers. 5. Embossed Pattern: The embossed pattern adds depth and visual interest with raised designs or patterns on the sheet's surface. It is ideal for decorative purposes, signage, and branding applications. 6. Brushed Pattern: The brushed pattern creates a sleek and modern look by giving the aluminum sheet a uniform directional grain. It is often used for architectural accents, kitchen backsplashes, and appliances. 7. Ribbed Pattern: The ribbed pattern features parallel raised ridges or lines on the sheet's surface, offering improved strength and rigidity. It is suitable for applications that require structural support or reinforcement. These examples showcase the variety of patterns available for aluminum sheets. When selecting the right pattern for a specific application, it is essential to consider the specific requirements and desired aesthetic.

- Q: What is the typical price range for aluminum sheets?

- The typical price range for aluminum sheets can vary depending on factors such as size, thickness, and quality. However, generally speaking, aluminum sheets can range anywhere from $0.25 to $3 per square foot.

- Q: Can the aluminum sheets be used for manufacturing electrical connectors?

- Yes, aluminum sheets can be used for manufacturing electrical connectors. Aluminum is a good conductor of electricity and is commonly used in the production of electrical connectors due to its lightweight, corrosion resistance, and cost-effectiveness.

- Q: Are aluminum sheets resistant to impact and vibration?

- Yes, aluminum sheets are generally resistant to impact and vibration. Aluminum is known for its high strength-to-weight ratio, making it a durable and lightweight material. It has good mechanical properties, including excellent resistance to impact and vibration. Aluminum sheets are often used in applications that require protection against impact and vibrations, such as automotive parts, aircraft structures, and building facades. Additionally, aluminum can be alloyed with other elements to enhance its impact resistance and reduce vibrations. Overall, aluminum sheets are a reliable choice for withstanding impact and vibration forces.

- Q: Are 101 aluminum sheets suitable for radiator manufacturing?

- Indeed, 101 aluminum sheets prove to be fitting for the production of radiators. This particular aluminum alloy, known as 101 aluminum, boasts a pure composition that lends itself to exceptional thermal conductivity, making it a prime choice for radiator utilization. Moreover, its remarkable resistance to corrosion proves pivotal in radiator applications that frequently entail contact with water and other fluids. Furthermore, the lightweight nature and ease of manipulation of 101 aluminum sheets facilitate efficient processes for radiator manufacturing. In summary, the desired properties and characteristics essential for the creation of radiators are duly satisfied by 101 aluminum sheets.

- Q: Are aluminum sheets suitable for lightweight structures?

- Indeed, aluminum sheets prove to be a fitting choice when it comes to lightweight structures. Renowned for its low density and impressive strength-to-weight ratio, aluminum emerges as an optimal material for applications requiring reduced weight. Industries such as aerospace, automotive, and construction frequently rely on aluminum sheets due to their exceptional corrosion resistance, durability, and malleability. These properties facilitate effortless fabrication and installation. Moreover, the versatility of aluminum sheets extends to their effortless joining through diverse welding and adhesive methods, thereby bolstering their aptness for lightweight structures.

- Q: What is the typical lead time for ordering aluminum sheets?

- The typical lead time for ordering aluminum sheets can vary depending on various factors such as the supplier, the quantity of sheets ordered, and the current demand for aluminum. However, in general, lead times for ordering aluminum sheets can range from a few days to several weeks. For standard-sized aluminum sheets that are readily available in stock, the lead time is usually shorter, typically ranging from a few days to a week. This is because suppliers often have these common sizes in their inventory and can ship them out quickly. On the other hand, if you require custom-sized aluminum sheets or a large quantity that is not readily available, the lead time may be longer. In such cases, the supplier may need to source the aluminum, cut it to the desired size, and process any necessary treatments or finishes. This process can take several weeks, especially if the supplier has a high volume of orders or if the aluminum needs to be imported. It is important to communicate with the supplier to determine the specific lead time for your order. They will be able to provide you with an estimated timeframe based on their current production capacity, stock availability, and any other factors that may impact the lead time.

- Q: Are aluminum sheets suitable for decorative screens?

- Yes, aluminum sheets are suitable for decorative screens. They are lightweight, durable, and can be easily customized into various shapes and designs. Additionally, aluminum's corrosion resistance makes it suitable for both indoor and outdoor applications, making it a popular choice for decorative screens.

- Q: There are about 200 holes on the aluminum plate to be machined. There are 100 M12 thread holes, and the rest are 15MM through holes. The tolerance is +0.02. Seeking detailed processing technology, is the first hole or first processing plane, how to control the amount of deformation of the plate, if the milling process can not guarantee flatness, on the grinder, then the 2 surfaces to stay 2MM margin? Are there any 15MM through holes that can be used to maintain tolerances, or do they need to be boring?. Great God advice, the best detail. Aluminum so much done before, no experience, if it does it scrapped.

- The thickness of 2 to 1. fly in place stress to ensure the flatness of the fitter leveling 0.13 more than the Xicheng pay attention to the protection of the appearance of 4 to ensure the flatness of the fabricated fitter. - this thing must not need to be so high, 100 M12 threaded holes, you still press the map to ensure that ah? Such a large plate deformation, 2 millimeters below the hole can be pressed to do

Send your message to us

5052 125 Mill Finish Aluminum Sheet 5xxx Series Alloy for Automotive Body

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords