Diamond Plate Aluminum Sheets 3xxx Series Alloy for Automotive Body - Mill Finish

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminum Sheet 3XXX Series Alloy for Automotive Body

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

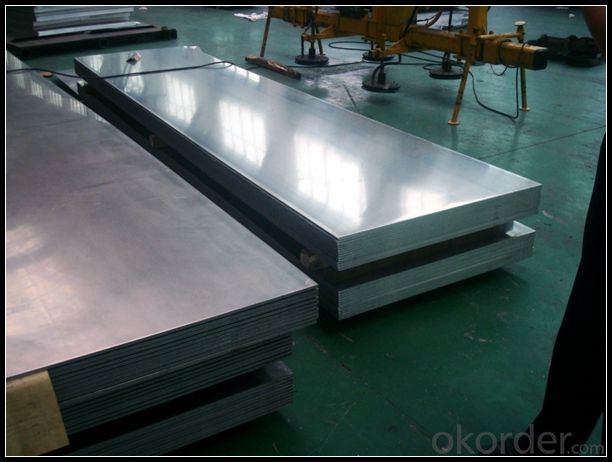

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Mill Finish Aluminum Sheet 3XXX Series Alloy for Automotive Body

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminum Sheet 3XXX Series Alloy for Automotive Body

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

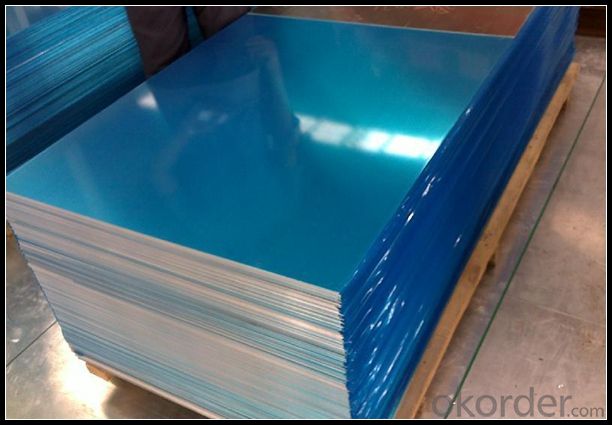

5. Image of Mill Finish Aluminum Sheet 3XXX Series Alloy for Automotive Body

6. Package and shipping of Mill Finish Aluminum Sheet 3XXX Series Alloy for Automotive Body

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the different grades or alloys of aluminum available for sheets?

- There are several different grades or alloys of aluminum available for sheets, including 1100, 3003, 5052, and 6061. These grades vary in terms of their composition, strength, and suitability for different applications. For example, 1100 is a pure aluminum alloy with excellent corrosion resistance, while 3003 offers improved strength and workability. 5052 is known for its high fatigue strength and good weldability, and 6061 is a versatile alloy with excellent machinability and medium strength.

- Q: What specific criteria or conditions must be met when utilizing high-quality aluminum sheets in construction?

- <p>High-quality aluminum sheets used in construction projects require adherence to specific standards. They must possess high strength, corrosion resistance, and durability to withstand environmental conditions. Compliance with industry standards such as ASTM or ISO is crucial. Additionally, the sheets should be compatible with other construction materials and meet safety regulations. Proper installation techniques and qualified personnel are also essential to ensure the integrity and longevity of the construction project.</p>

- Q: What is the most efficient and low cost method for welding 1mm-3mm aluminum sheet?,What's new?

- Welding methods almost all kinds of welding methods can be used for welding aluminum and aluminum alloy, but the adaptability of aluminum and aluminum alloy to various welding methods is different, and various welding methods have their respective application. Gas welding and SMAW method, simple equipment, convenient operation. The gas can be used for welding of aluminum plate and casting of high welding quality requirements. Electrode arc welding can be used for repairing welding of aluminium alloy castings. Inert gas shielded welding (TIG or MIG) is the most widely used method for welding aluminum and aluminum alloys. Tungsten and argon arc welding or tungsten arc argon arc welding can be used for aluminum and its alloy sheets. Aluminum and aluminium alloy heavy plates can be made of tungsten helium arc welding, argon helium tungsten gas welding, MIG welding and pulse MIG welding. MIG welding and pulse MIG welding are more and more widely used (argon or argon / helium)Laser welding machine can also be used

- Q: What is aluminium plate for?

- Two outdoor and indoor, outdoor curtain wall decoration, indoor ceiling (such as aluminum pinch plate, aluminum grille, aluminum hanging tablets, etc.), color diversity, but also can be made imitation wood grain, imitation marble and other colors, widely used

- Q: This question asks about the structural integrity and suitability of aluminum sheets for use in the construction of high-rise buildings.

- <p>Aluminum sheets are not typically used as the primary structural material in high-rise buildings due to their lower strength compared to steel and concrete. However, aluminum is known for its high strength-to-weight ratio, making it suitable for non-structural applications such as facades, window frames, and roofing. In high-rise construction, aluminum can be used in combination with other materials to provide a lightweight and aesthetically pleasing exterior while maintaining structural integrity with stronger materials like steel and concrete.</p>

- Q: Are aluminum sheets resistant to impact?

- Yes, aluminum sheets are generally resistant to impact due to their high strength-to-weight ratio and ability to absorb and distribute energy.

- Q: Can aluminum sheet be used for automotive body panels?

- Automotive body panels can indeed utilize aluminum sheets. In fact, aluminum is gaining popularity in the automotive industry due to its numerous advantages. Firstly, aluminum surpasses steel in terms of weight, leading to improved fuel efficiency and overall vehicle performance. Furthermore, aluminum boasts high resistance to corrosion, providing durability for body panels exposed to the elements. Additionally, aluminum exhibits remarkable formability, enabling the creation of intricate designs and enhancing design flexibility during vehicle production. Moreover, aluminum excels in absorbing crash impact, thereby enhancing vehicle safety. Nevertheless, it is important to acknowledge that utilizing aluminum for automotive body panels may necessitate specialized equipment and techniques for welding and repair purposes.

- Q: Are aluminum sheets suitable for automotive body framing?

- Yes, aluminum sheets are suitable for automotive body framing. Aluminum is lightweight, corrosion-resistant, and offers excellent strength-to-weight ratio, making it an ideal choice for reducing vehicle weight and improving fuel efficiency. It is commonly used in modern automotive manufacturing for body panels and frames, providing structural integrity while maintaining durability.

- Q: What's the difference between laser cutting aluminum plate and stainless steel plate?

- The aluminum plate is higher than the stainless steel reflectivity, the focal point, the power, the speed are not the same, the general carbon dioxide laser does not have the anti - reflection lens, then had better not cut the aluminum plate, easy to burn the laser internal lens.

- Q: How do aluminum sheets perform in terms of creep resistance?

- Aluminum sheets generally exhibit good creep resistance, especially when compared to other metals. Aluminum has a low melting point and high thermal conductivity, which helps in reducing creep deformation. It also has a fine-grained microstructure that enhances its resistance to creep. However, it is important to note that the creep resistance of aluminum sheets can be affected by factors such as temperature, load, and alloy composition.

Send your message to us

Diamond Plate Aluminum Sheets 3xxx Series Alloy for Automotive Body - Mill Finish

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords