AISI SAE4140 Alloy Structural Steel Round Bar SCM440

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

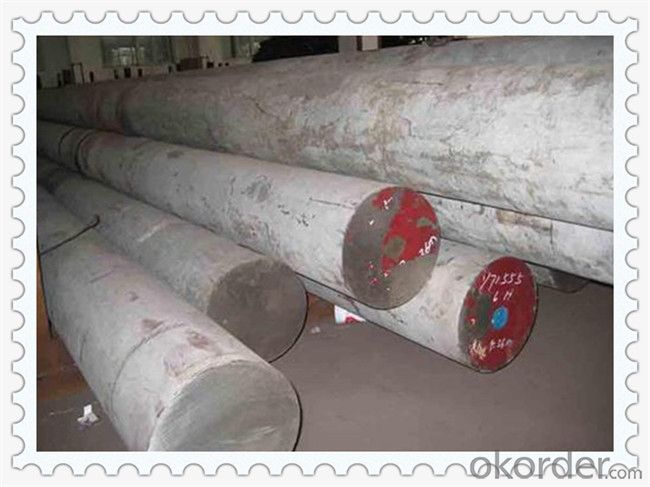

AISI SAE4140 Alloy Structural Steel Round Bar SCM440

1 Standards and Chemical Composition:

GB-China | AISI-America | DIN-Germany | JIS-Japan |

42CrMo | 4140 | 1.7225 42CrMo4 | SCM440 |

Grade | C | Si | Mn | P | S | Cr | Mo |

SAE4140 | 0.38/0.43 | 0.15/0.35 | 0.75/1.00 | ≤0.035 | ≤0.035 | 0.80/1.10 | 0.15/0.25 |

2 Mechanical Property:

Strength of extension | 1080MPA |

Yield point | 930MPA |

Elongation | 12% |

Contractibility rate | 45% |

Impacting energy | 63J |

3 Brief Introduction:

Dimension | 14-350mm |

Length | 2-13m or as per your request |

Delivery condition | Hot rolled |

Heat Treatment | Normalizing, Annealing, Quenching |

Packing | Standard seaworthy packing or according to your requirements |

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

We are a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

We provide the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the different types of steel used in round bars?

- There are several types of steel commonly used in round bars, including carbon steel, alloy steel, stainless steel, and tool steel.

- Q: On the market, 8mm Round Bar is not 9 meters a root? How much does it weigh about 300 meters? How much does it cost?

- 8 there is no regular reinforced steel bars are straight, round, there is straight, as you said 9 M 1, but that's rolling, if their home, can also, engineering is prohibited

- Q: Can steel round bars be coated for improved aesthetics?

- Yes, steel round bars can be coated for improved aesthetics. Coating steel round bars can enhance their appearance by providing a more polished and visually appealing surface. There are various coating options available, such as powder coating, electroplating, or painting, which can be applied to steel round bars to achieve different aesthetic effects. These coatings not only enhance the appearance of the bars but also provide additional benefits such as corrosion resistance and durability. Therefore, coating steel round bars is a common practice to improve their aesthetics in various applications including architectural, decorative, and industrial purposes.

- Q: What kind of material is the first round steel?

- [a round bar] is a smooth steel bar. The title of the old bar code, usually called HPB300, is a grade bar, H (Hot-rolled) means hot rolled, P (Plain) is smooth, B (Bar) is strip, where steel is used, and 300 represents yield strength of 300 MPa

- Q: What are the considerations for selecting the right steel grade for a round bar?

- There are various factors to consider when choosing the appropriate steel grade for a round bar. To begin with, the intended application of the round bar should be taken into account. Different steel grades possess distinct properties that make them suitable for specific purposes. For instance, stainless steel or high-alloy steel, which have exceptional heat resistance, would be ideal for use in high-temperature environments. Conversely, carbon steel, with its good strength and ductility, may be more appropriate for structural applications. Another factor to consider is the desired mechanical properties of the round bar, including tensile strength, yield strength, hardness, and toughness. These properties can vary significantly among different steel grades, so it is crucial to select a grade that meets the specific requirements of the application. Corrosion resistance is also an important consideration. If the round bar will be exposed to corrosive environments, such as in marine or chemical applications, it is advisable to choose a stainless steel grade with high resistance to corrosion. On the other hand, if corrosion resistance is not a major concern, a carbon steel grade may be more cost-effective. Cost is another factor to be taken into account. Different steel grades have varying costs based on availability, demand, and manufacturing processes. It is important to strike a balance between the desired properties of the round bar and the available budget to ensure cost-effectiveness. Moreover, the manufacturability of the steel grade should be considered. Some steel grades may be more challenging to machine or weld, which can impact the production process and cost. It is crucial to select a readily available steel grade that can be easily processed to meet the required specifications. Finally, it is always advisable to seek guidance from steel suppliers, engineers, or metallurgists to ensure that the chosen steel grade aligns with the specific requirements of the application. Their expertise and experience in the industry can provide valuable insights and recommendations.

- Q: Can steel round bars be coated or painted?

- Steel round bars have the capability to undergo coating or painting. The purpose of coating or painting steel round bars is manifold; it prevents corrosion, enhances aesthetics, and provides additional protection against environmental factors. There are several methods available for applying coatings and paints to steel round bars, including powder coating, electroplating, or wet paint application. These processes involve first preparing the surface of the steel round bar by removing any existing rust or contaminants, and then applying the chosen coating or paint. The selection of the appropriate coating or paint depends on the specific requirements of the steel round bars, such as their intended use, environmental conditions, and desired appearance. By coating or painting steel round bars, their lifespan can be significantly extended, their visual appeal can be improved, and their durability can be ensured in a wide range of applications.

- Q: What are the weight calculations for steel round bars?

- The weight calculations for steel round bars depend on the diameter and length of the bar. The formula used to calculate the weight is weight = volume × density, where volume = π × (diameter/2)² × length and density = 7.85 g/cm³.

- Q: What are the different types of steel used in manufacturing round bars?

- Round bars in manufacturing can be made from various types of steel. The most commonly used types include: 1. Carbon Steel: This is the go-to steel for manufacturing round bars due to its strength and durability. It mainly consists of iron and carbon and finds application in construction, automotive, and machinery. 2. Alloy Steel: By adding elements like manganese, nickel, chromium, and molybdenum to carbon steel, alloy steel is formed. This enhances its strength and hardness, making it suitable for applications that demand high strength and resistance to wear and tear. 3. Stainless Steel: A type of alloy steel, stainless steel contains a minimum of 10.5% chromium. This high chromium content gives it excellent corrosion resistance, making it ideal for applications exposed to moisture or chemicals. Stainless steel round bars are commonly used in kitchen utensils, medical equipment, and automotive parts manufacturing. 4. Tool Steel: Tool steel is an alloy steel designed specifically for high hardness, wear resistance, and heat resistance. It is commonly used in manufacturing cutting tools, dies, and molds. Tool steel round bars are usually made from high-carbon steel with additional elements like tungsten, vanadium, or cobalt. 5. Bearing Steel: Bearing steel is an alloy steel specifically formulated for bearing applications. It is characterized by its high hardness, wear resistance, and fatigue strength. Bearing steel round bars are widely used in bearing manufacturing for industries like automotive, aerospace, and industrial machinery. These examples demonstrate the range of steel types available for manufacturing round bars. The specific choice of steel depends on the desired properties and requirements of the application at hand.

- Q: Can steel round bars be used in high-temperature applications?

- Yes, steel round bars can be used in high-temperature applications. Steel is known for its strength and durability, and it can withstand high temperatures without deformation or loss of structural integrity. However, the specific type of steel and its composition will determine its suitability for high-temperature applications. Stainless steel, for example, has excellent heat resistance and can be used in a wide range of high-temperature environments. Additionally, certain alloy steels are specifically designed for use in high-temperature applications, such as those found in the aerospace or petrochemical industries. It is important to consult with experts and consider the specific requirements of the application to ensure the appropriate steel round bars are chosen for high-temperature conditions.

- Q: Weight algorithm of round steel

- 1, the appearance is different, round steel appearance of round, no grain without ribs, other steel surface appearance has carved or ribbed, this causes the round bar and concrete bonding force is small, and other steel and concrete bonding force.2 ingredients are different, round steel (grade a steel) belongs to ordinary low carbon steel, and other steel bars are mostly alloy steel. 3 strength, steel and other steel with high strength low strength, namely, diameter of the same size as compared with other steel, round steel can bear the pulling force than other reinforced small, but the plastic steel reinforced bar is stronger than the other, there is a large deformation in the break before, and it reinforced the deformation the break before the much smaller.

Send your message to us

AISI SAE4140 Alloy Structural Steel Round Bar SCM440

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords