Steel Sheet Hot Rolled Stainless Steel Thickness 4.0mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description for Stainless Steel Coils/Sheets:

Material | 201/202/301/304/304L/310S/316/316L/321/410/420 |

Technique | old Rolled, Cold Drawn, Hot Rolled |

Standard | ASTM,AISI,JIS,GB,DIN,EN |

Thickness | 0.3mm-100mm or as your requirement |

Width | 100mm-3000mm or as your requirement |

Length | 1000mm-10000mm or as your requirement |

Surface Treatment | BA,2B,No.1,No.4,No.8,HL,8K,Brush |

Packing | 1.Export sea worthy package + water proof paper + wooden pallet 2. Max Loading 26.5mt for each 20Gp container 3.Safe loading and fixing Professiona teams 4. Professional shipping line |

Delivery | 25 days after received the 30% deposit of T/T or L/C |

Payment | T/T,30%payment in advance,70%T/T after the copy of B/L or L/c at sight |

Application | Stainless Steel Sheets are widely used in below fields: 1: Construction field, shipping building industry 2: Petroleum and Chemical Industries 3: Food and Mechanical Industries |

Specifications for Stainless Steel Coils/Sheets:

Grade | C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Ni ≤ | Cr ≤ |

201 | 0.12 | 0.75 | 7.00 | 0.045 | 0.045 | 1.00-1.28 | 13.70-15.70 |

202 | 0.15 | 1.00 | 2.25 | 0.045 | 0.045 | 4.07-4.17 | 14.00-16.00 |

304 | 0.08 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

304L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-13.00 | 18.00-20.00 |

309 | 0.15 | 0.75 | 2.00 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

310S | 0.08 | 1.50 | 2.00 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

316L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 10.00-15.00 | 16.00-18.00 |

321 | 0.04-0.10 | 0.75 | 2.00 | 0.045 | 0.03 | 9.00-13.00 | 17.00-20.00 |

405 | 0.08 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

409 | 0.089 | 1.00 | 1.00 | 0.045 | 0.05 | 0.06 | 10.50-11.75 |

410 | 0.15 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

420 | 0.16-0.25 | 1.00 | 1.00 | 0.040 | 0.03 | 0.06 | 12.00-14.00 |

430 | 0.12 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 16.00-18.00 |

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

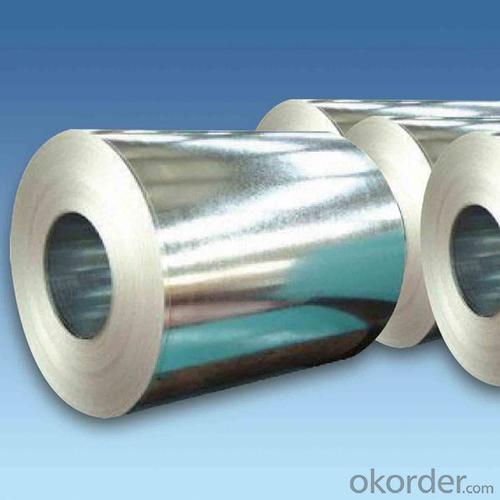

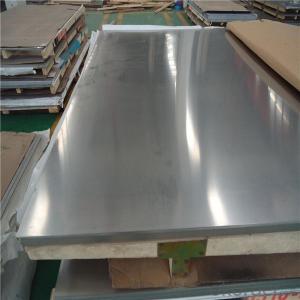

Detail picture for Stainless Steel Coils/Sheets

Application of Stainless Steel Coils

(1)Boiler heat exchanger,

(2)Chemical industries,

(3)Hardware fields,

(4)Construction material,

(5)Kitchen utensils,

(6)Building construction,

(7)Medical equipment,

(8)Chemical tank,

(9)Pipe etc

FAQ for Stainless Steel Coils/Sheets:

Q: How can I get the samples?

A: If you need some samples to test ,please pay for the transportation freight of samples and our samples are free for you.

Q: How can I get your price list?

A: Please send us your email or fax and order information – Quantity, Specification (steel type, thickness, width, surface finish), then I can send you the price list.

- Q: Are stainless steel sheets suitable for food processing or medical applications?

- Yes, stainless steel sheets are highly suitable for food processing and medical applications. Stainless steel is a popular choice in these industries due to its numerous beneficial properties. Firstly, stainless steel is resistant to corrosion, making it ideal for environments where hygiene and cleanliness are of utmost importance, such as food processing plants and medical facilities. Secondly, stainless steel is a non-porous material, meaning it does not absorb or retain bacteria, germs, or odors. This makes it easy to clean and maintain high levels of sanitation, crucial in food processing and medical settings where contamination must be minimized. Additionally, stainless steel has excellent strength and durability, allowing it to withstand harsh conditions, heavy use, and frequent cleaning without deteriorating. This makes stainless steel sheets a reliable and long-lasting choice for these demanding applications. Furthermore, stainless steel is non-reactive with food and many medical substances, ensuring that it does not leach any harmful chemicals or contaminants into the products being processed or the patients being treated. This is crucial for maintaining the safety and integrity of both food and medical materials. In conclusion, stainless steel sheets are highly suitable for food processing and medical applications due to their corrosion resistance, non-porous nature, strength, durability, and non-reactive properties. Choosing stainless steel ensures the highest standards of hygiene, cleanliness, and safety in these industries.

- Q: What is the price per square foot for stainless steel sheets?

- The price per square foot for stainless steel sheets can vary depending on various factors such as the grade, thickness, finish, and supplier. On average, stainless steel sheets can range from $3 to $10 per square foot. However, high-quality and specialty stainless steel sheets can be priced higher, reaching up to $20 or more per square foot. It is important to consider these factors and shop around to find the best price for your specific requirements.

- Q: Can stainless steel sheets be used for decorative elevator doors or panels?

- Yes, stainless steel sheets can be used for decorative elevator doors or panels. Stainless steel is a versatile material that offers a polished and modern appearance, making it a popular choice for decorative applications. It is known for its durability, resistance to corrosion, and easy maintenance, making it suitable for high-traffic areas like elevator doors and panels. Additionally, stainless steel sheets can be customized with various finishes, patterns, and textures, allowing for endless design possibilities. Whether it's a sleek and minimalist look or a more intricate and decorative design, stainless steel sheets can enhance the aesthetics of elevator doors and panels while providing long-lasting functionality.

- Q: What are the different types of stainless steel sheet surface finishes available?

- There are several different types of stainless steel sheet surface finishes available, each with its own unique characteristics and uses. Some of the most common types include: 1. No. 1 Finish: This is the most basic and commonly used finish, also known as hot rolled annealed and pickled (HRAP). It has a rough, dull appearance with visible grain lines and is typically used for industrial applications where aesthetics are not a major concern. 2. No. 2B Finish: This finish is achieved by cold rolling, heat treating, and pickling the stainless steel. It has a smooth, reflective surface with a moderate gloss and is commonly used for applications that require a clean, uniform appearance, such as kitchen appliances and architectural components. 3. No. 3 Finish: This finish is achieved by using progressively finer abrasives during the polishing process. It has a semi-polished, satin-like appearance with visible grain lines and is often used for decorative applications, such as furniture, signage, and automotive trim. 4. No. 4 Finish: This finish is similar to No. 3, but with a finer grain and higher gloss. It is achieved by using even finer abrasives during the polishing process and is commonly used for architectural and decorative applications that require a high-quality, mirror-like finish. 5. No. 8 Finish: Also known as a mirror finish, No. 8 is the highest-quality stainless steel sheet surface finish available. It is achieved by polishing the stainless steel to a highly reflective, mirror-like appearance. This finish is often used for high-end architectural and decorative applications where a premium, flawless finish is desired. In addition to these primary finishes, there are also specialized finishes available for specific applications. For example, a brushed finish creates a textured, brushed appearance by using abrasive belts or brushes against the stainless steel surface. Additionally, there are colored finishes that involve applying a thin layer of color to the stainless steel surface, providing a unique and eye-catching appearance. Overall, the choice of stainless steel sheet surface finish depends on the specific application and desired aesthetics, ranging from basic industrial finishes to high-end decorative finishes.

- Q: Can stainless steel sheets be used for elevator handrails or grab bars?

- Yes, stainless steel sheets can be used for elevator handrails or grab bars. Stainless steel is a common material used for these applications due to its durability, corrosion resistance, and aesthetic appeal. It is able to withstand heavy use and provides a secure grip, making it suitable for elevator handrails and grab bars.

- Q: What is the water resistance of stainless steel sheets?

- The water resistance of stainless steel sheets is typically high due to their nonporous nature and corrosion-resistant properties.

- Q: Can stainless steel sheets be used for elevator interiors?

- Yes, stainless steel sheets can be used for elevator interiors. Stainless steel is a popular choice for elevator interiors due to its durability, sleek appearance, and resistance to corrosion and wear. It provides a clean and modern look, making it a suitable material for elevators in commercial buildings, hotels, and other high-traffic areas.

- Q: What are the different types of stainless steel sheet edge treatments available?

- Some of the different types of stainless steel sheet edge treatments available include mill edge, slit edge, deburred edge, and rounded edge. Mill edge refers to the untreated, raw edge of the sheet as it comes from the mill. Slit edge refers to the edge that is produced after the sheet has been slit into narrower widths. Deburred edge is a smooth, polished edge that has been treated to remove any sharp edges or burrs. Rounded edge is a curved edge that is created by rounding off the corners of the sheet. These different edge treatments cater to different applications and preferences for the appearance and safety of the stainless steel sheet.

- Q: Can stainless steel sheets be used in the automotive industry?

- Yes, stainless steel sheets can be used in the automotive industry. Stainless steel is often used due to its high strength, corrosion resistance, and durability. It is used for various components such as exhaust systems, body panels, frames, and interior trim.

- Q: Are stainless steel sheets suitable for chemical reactors?

- Yes, stainless steel sheets are suitable for chemical reactors. Stainless steel is a preferred material in the chemical industry because of its excellent corrosion resistance properties. It can withstand a wide range of chemicals, including acids, alkalis, and solvents, without undergoing significant degradation or reacting with the substances being processed. Stainless steel sheets are particularly chosen for chemical reactors due to their high strength, durability, and resistance to high temperatures and pressure. They can handle the harsh conditions and aggressive substances found in chemical processes without compromising their structural integrity. Moreover, stainless steel sheets are easy to clean and maintain, making them suitable for applications where cleanliness is crucial, such as pharmaceutical and food processing industries. They also have excellent heat transfer properties, allowing for efficient temperature control within the reactor. In summary, stainless steel sheets are a reliable choice for chemical reactors due to their corrosion resistance, strength, durability, and thermal properties. They provide a safe and long-lasting solution for handling various chemicals, making them widely used in the chemical industry.

Send your message to us

Steel Sheet Hot Rolled Stainless Steel Thickness 4.0mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords