St52 Seamless Delivery Pipe for Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

St52 Seamless Delivery Pipe for Concrete Pump

1. Structure of St52 Seamless Delivery Pipe for Concrete Pump:

Include four types

St52 Weld Pipe: Main use for Trailer-mounted pump, thickness has 4.0mm, 4.5mm, 5mm. Compare with for Truck-mounted pump. Weld pipe has cheaper price, so it is popular in Saudi, Pakistan, India, etc. Unit Price is about 30USD-33USD.

St52 Seamless Pipe: Now More People like use this kind for Truck Pump and Trailer Pump because of the quality is better and it is seamless kind, so this kind pipe is most popular in Middle East Price About 34USD-37USD.

2. Main Features of St52 Seamless Delivery Pipe for Concrete Pump:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Ensure the supply of ancillary parts

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

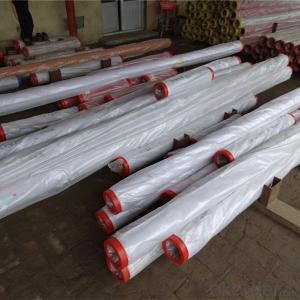

3. St52 Seamless Delivery Pipe for Concrete Pump Images:

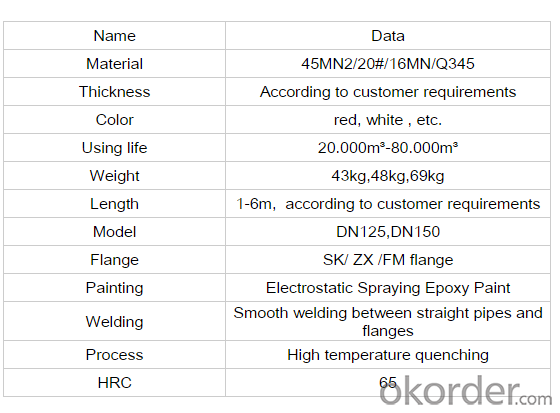

4. St52 Seamless Delivery Pipe for Concrete Pump Specification:

Name | Structure | Specification | Weight | Life time | Impact force | Notched bar impact strength | Max. work press |

Normal wear resistant pipe | Single | DN125*3000mm | 48kgs | 6000 - 8000 | ≥45 | ≥27 | 36 bar |

Economic wear resistant pipe | Single | DN125*3000mm | 45kgs | 18000 - 22000 | ≥47 | ≥28 | 93 bar |

Construction wear resistant pipe | Single | DN125*3000mm | 45kgs | 20000 - 25000 | ≥47 | ≥28 | 93 bar |

Diamond wear resistant pipe | Single | DN125*3000mm | 44kgs | 25000 - 35000 | ≥47 | ≥38 | 93 bar |

W12-5 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 50000 - 60000 | ≥ 42 | ≥25 | 59 bar |

W12-8 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 60000 - 80000 | ≥ 43 | ≥25 | 59 bar |

GX350-1 wear resistant pipe | Twin | DN125*3000mm | 44kgs | 80000 - 100000 | - | - | 34 bar |

GX350-2 wear resistant pipe | Twin | DN125*3000mm | 68kgs | 120000 - 150000 | - | - | 76 bar |

5. FAQ:

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

6. Why choose us:

• We are a comprehensive manufacturing and trading company.

• We have been specialized in producing concrete pump spare parts and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

• We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q: In the design of large machinery, it is to design the parts first, the assembly drawings as well

- First of all, the transmission mechanism must be defined first, and then the strength of the transmission system must be calculated, and then the actual size, gear modulus and so onThen draw parts, assemble, assemble problems, and then change parts

- Q: What exactly is mechanical design?

- Mechanical design (machine, design),According to the requirement of the mechanical structure, working principle, motion, force and energy transfer, the various parts of the material and shape size and lubrication methods for design, analysis and calculation and put it into specific description as a basis for the manufacturing process.

- Q: An analog aircraft equipment, in the middle of the two electric cylinder to provide equipment up and down force, two electric cylinders are together and synchronized up and down movement (should be an electric cylinder support force is not enough?) I understand so, so it can only provide the upper and lower forces, the front and left of the three directions, each one of the black rod-shaped structure is how to provide the equipment about deviation, upward and downward deflection of the force? At the same time, how to make these forces achieve controllable effect, complete flight simulation?If cannot send the video address to BIRDLY Baidu flight simulator with complete video, can be seen with me after the detailed explanation, there can also be additional points I'm curious about design of the structure, the answer may take some time and I say that with QQ

- Mechanical design, the analysis of the role of the entity rhythm, WO wrote two articles, which can be referred to you.

- Q: The strength criterion of mechanical parts design is briefly introduced

- 1, the strength criterion requires that the working stress of the mechanical parts should not exceed allowable stress [Sigma]. The formula is typical: (3-16) lim - ultimate stress of brittle materials by static stress on the ultimate strength, the static stress of plastic materials, the yield limit of zero stress the fatigue limit. S - Safety factor. 2. stiffness criteria mechanical components are subject to elastic deformation when subjected to load. Stiffness is the ability to resist deformation of materials, mechanical parts, or structures subjected to external forces. The stiffness of the material is measured by the external force required to produce the unit deformation. The stiffness of a mechanical part depends on its modulus of elasticity, E or shear modulus, G, geometry and size, and the form of external forces. It is an important work in mechanical design to analyze the rigidity of mechanical parts. For some parts that need to be strictly deformed (such as wings, machine tools, spindles, etc.), stiffness analysis is necessary to control the deformation. We also need to control the stiffness of the parts to prevent vibration or instability. In addition, a spring, such as a spring, must be used to control its stiffness to a reasonable value to ensure its specific function. The stiffness criterion is that the elastic deformation of a component subjected to load is not greater than the allowable elastic deformation. The expression of the stiffness criterion is (3 - 17) y is an elastic deformation quantity, such as deflection, longitudinal elongation (shortening): [y] is the corresponding allowable elastic deformation. The elastic deformation of a part can be obtained by theoretical calculation or by experiment. The allowable deformation depends on the use of the part, and is determined by theoretical analysis or experience.

- Q: I designed a great bike with my own mechanical design software. Now I keep it in the computer. What I want to ask isHow do you get these components of the same size, give them the money in the factory, and then make them as planned? Give me a clue, such as magnesium alloy, carbon steel, and so on

- Yes, I'm looking for an outside manufacturer to help you make the parts. First, I'll show them the drawings and let them quote the delivery date, and then sign the contract

- Q: Fixture assembly drawings, detailed parts drawings, design instructions, machining processes, integrated cards, and process cards will be added

- I was engaged in mechanical design and process about 10 years, are of their own design what is responsible for processing, the above parts is very simple, need to look at the parts of the mass in the factory to determine the blank shape, need to consider many, encouraging learning tyrants to stop showing off to the society, how to look and learn!

- Q: I am a bachelor degree in industrial design and have been sitting here for two months now, 20The feeling is still not understand, not figure painting, other colleagues are busy, I could not ask, do not know how to do, give me a leading figure today, let me figure it out on my own, I draw more and more have no confidence, I do not know because many mechanical components, do not know how to do.. Tired ~ ~ mechanical aspects of the great God, I pointed to the Ming road! Thanks

- Do not understand to communicate with people ah ~ you can truthfully and under the leadership of the reaction, find a master under guidance

- Q: Before listening to the teacher mentioned that, when the design of components, we should take into account the actual processing capacity of the factory, and some look very simple things, the factory is unable to process! I want to know what the reason is!!!

- The key is and plant equipment and the level of the workers, such as some complex tooling, laser cutting or five axis machining center type of equipment can be processed, it needs to consider the economic.Another example is that the suspension part of mark 206 has a part, but if the layman sees a simple shaft type parts, it can not be nationalized, because its precision requirements are too high and can only be imported, and so on

- Q: University contact with some simple PLC, ladder diagram, but also to understand.I University of mechanical manufacturing, graduate students made a machine tool parts, mechanical design, University contact with some simple PLC, ladder diagram, but also to understand. Now work in contact with CNC machine tools, want to learn some numerical control system, electrical knowledge, to the job after adding some capital. Online to find some 840D information, that means too hard to see, what NCU, PCU, wiring, address completely do not understand. How do I study?

- Can go to the direction of mechanical and electrical integration, good use of their own advantages. These do not understand, you can find under the internet.

- Q: In the process of mechanical design, those areas should be designed as fillet and when to design chamfer. These materials can be found in those places, and the title of the book is also OK. Thank you!

- Fillet is generally cast out, chamfering is generally processed out.In order to eliminate stress concentration, a cylindrical part needs to be rounded in order to eliminate the stress concentration.In general, the outer circle, the inner hole and the threaded orifice need chamfering, some are the process requirements, some are assembly requirements (for example, you don't chamfer the parts, especially the smaller ones)...The old saying upstairs is what I want to say. I hit half and found it was called back

Send your message to us

St52 Seamless Delivery Pipe for Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords