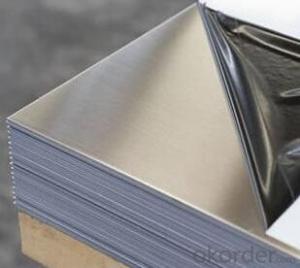

304 Stainless Steel Sheet Brushed Surface with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

304 stainless steel sheet brushed surface with high quality.

Product Description

Specification of 304 stainless steel sheet brushed surface

1. Material: 300series

2. Standard: JIS, AISI, ASTM, GB, DIN, EN

3. Thickness: 0.3-100mm or as customer’s requirement

4. Width: 1500-2200mm or as customer’s requirement

5. Length: 1000-6000mm or as customer’s requirement

6. Surface: 2B, BA, No.1, etc

7. Technical processing: Hot Rolled/Cold Rolled

8. Decoration:

Mirror, No.4, HL NSP, Bead Blast, Vibration,

HL Gold, Mirror Gold, Vibration Gold NSP,

No4 Copper NSP, Mirror Copper, Bead Copper,

HL Brass, Mirror Brass, Bead Brass,

HL Black, Mirror Black, Bead Black NSP,

HL Bronz, Mirror Bronze, Vibration Bronze,

Mirror Etched, HL Etched Copper, Mirror Black Etched, Mirror Etched Gold.

Surface finish of 304 stainless steel sheet brushed surface

2B,BA,HL,SB,BK,NO.1,NO.2,NO.4,NO.8,Polish,PVC,Brush,Mirror,Pickled,Annealed etc.

Mechanical property of 304 stainless steel sheet brushed surface

| Tensile Strength | σb (MPa)≥520 |

| Offset Yield Strength | σ0.2 (MPa)≥205 |

| Elongation | δ5 (%)≥40 |

| Reduction of Area | ψ (%)≥60 |

| Hardness | ≤187HB;≤90HRB;≤200HV |

| Density(20℃,g/cm3) | 7.93 |

| Melting Point(℃) | 1398~1454 |

| Specific Heat Capacity(0~100℃,KJ·kg-1K-1) | 0.5 |

| Thermal Conductivity(W·m-1·K-1) | (100℃)16.3,(500℃)21.5 |

| Coefficient of Linear Expansion(10-6·K-1) | (0~100℃)17.2,(0~500℃)18.4 |

| Electrical Resistivity(20℃,10-6Ω·m) | 0.73 |

| Longitudinal Modulus of Elasticity(20℃,KN/mm2) | 193 |

Chemical composition of 304 stainless steel sheet brushed surface

| 304 | C | Mn | P | S | Si | Cr | Ni |

| % | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.030 | ≤1.00 | 17.5–20.0 | 8.0-11 |

Maintenance of 304 stainless steel sheet brushed surface

(1) Regular cleaning and maintenance

(2) Pay attention to prevent the occurrence of the phenomenon of surface scratches

(3) Use soap, weak detergent or warm water to remove surface dust, dirt

(4) In addition to the surface of the binder with alcohol or an organic solvent (ether, benzene)

(5) Use neutral detergent or ammonia solution in addition to surface oil

(6) With 10% nitric acid or abrasive detergent in addition to the surface of the embroider caused by the dirt.

Packaging & Shipping

Packaging way of stainless steel: Original packaging according to your needs. Standard export sea-worthy wooden packing.

Our Services

1.All product are made of high-quality stainless steel sheet;

2.We have good service & short delivery time;

3.We have professional export team;

4.We can provide sample for your evaluation;

5.We can provide Mill test certificate;

6.Your enquiry will get quickly and efficient response.

Why do you choose us?

1)Our products are high quality and best price.

2)We have experience in this line for many years.

3)We have professional team and the factory.

4)It's very important for a company to be honest in the process of trading and so do we.

5)Our products are exported to countries around the world.

- Q: What is the price per square foot for stainless steel sheets?

- The price per square foot for stainless steel sheets can vary depending on factors such as thickness, grade, and quantity. It is recommended to contact suppliers or check their websites for the most accurate and up-to-date pricing information.

- Q: Can stainless steel sheets be used for decorative wall panels?

- Yes, stainless steel sheets can be used for decorative wall panels. Stainless steel is a versatile material that can be easily shaped and manipulated to create various designs and patterns. It is known for its sleek and modern appearance, making it a popular choice for contemporary and industrial-style interiors. Stainless steel sheets are available in different finishes, such as brushed, mirrored, or textured, allowing for further customization and adding visual interest to the wall panels. Additionally, stainless steel is resistant to corrosion, durable, and easy to clean, making it suitable for high-traffic areas or environments prone to moisture or humidity. Overall, stainless steel sheets can provide a stylish and functional solution for decorative wall panels.

- Q: What are the different types of stainless steel sheet finishes for pharmaceutical applications?

- Pharmaceutical applications commonly utilize various stainless steel sheet finishes, each designed to meet specific requirements and provide certain characteristics and properties. 1. The most basic stainless steel sheet finish is No.1 Finish, with a rough and dull surface. It prioritizes corrosion resistance and durability over appearance. 2. No.2D Finish, also known as a "dull" finish, has a slightly smoother surface compared to No.1 finish. It is achieved through cold rolling and annealing, making it suitable for easy cleaning and maintenance in pharmaceutical applications. 3. No.2B Finish is highly popular in stainless steel sheets for pharmaceutical purposes. It boasts a smooth and reflective surface obtained through cold rolling, annealing, and pickling or passivating processes. No.2B finish offers exceptional corrosion resistance and easy cleaning properties. 4. No.3 Finish presents a semi-reflective surface with a slightly coarse texture. It is achieved by polishing the stainless steel sheet using a fine abrasive material. No.3 finish is commonly used when a decorative appearance is desired, while maintaining good corrosion resistance. 5. No.4 Finish is a favored choice for pharmaceutical applications that require both a decorative appearance and excellent corrosion resistance. It features a brushed appearance achieved by using a fine abrasive material in a linear motion. No.4 finish also provides a smooth surface that is easy to clean. 6. No.6 Finish, achieved by using a fine abrasive material in a circular motion, results in a satin-like appearance. It is often utilized in pharmaceutical applications where a high-quality aesthetic finish is desired, particularly for equipment visible to patients or visitors. To conclude, pharmaceutical applications benefit from a variety of stainless steel sheet finishes, each offering specific characteristics to meet industry needs. Whether prioritizing corrosion resistance, easy cleaning, or a decorative appearance, there is a suitable finish available for every pharmaceutical application.

- Q: What are stainless steel sheets?

- Stainless steel sheets, which are composed of stainless steel, a type of alloy containing chromium, nickel, and other elements, are metal pieces that have a flat shape. These sheets possess exceptional resistance to corrosion, durability, and aesthetic appeal, which makes them highly versatile and extensively utilized in various industries. To achieve the desired thickness and finish, they undergo a manufacturing process known as hot rolling or cold rolling, where the steel is passed through a series of rollers. Stainless steel sheets find common applications in the construction, automotive manufacturing, kitchenware, appliances, and architecture sectors. They are available in different grades, surface finishes, and sizes to meet various requirements. Regardless of whether they are used for decorative purposes or functional applications, stainless steel sheets provide a dependable and enduring solution.

- Q: How do you form stainless steel sheets into different shapes?

- Stainless steel sheets can be formed into different shapes through various processes such as bending, cutting, and welding. Bending can be achieved by using specialized tools like press brakes or rollers to apply force and reshape the sheet. Cutting techniques like shearing or laser cutting can be used to create desired shapes or sizes. Additionally, welding is employed to join different stainless steel sheets together, enabling the formation of complex structures and shapes.

- Q: Can stainless steel sheets be used in marine environments?

- Yes, stainless steel sheets can be used in marine environments. Stainless steel is highly resistant to corrosion, making it suitable for marine applications where it will be exposed to saltwater and high humidity. It is commonly used in marine vessels, offshore platforms, and other structures that require durability and resistance to rust and corrosion.

- Q: What are the different types of corrosion that stainless steel sheets can resist?

- Stainless steel sheets are known for their exceptional corrosion resistance compared to other metals. There are several types of corrosion that stainless steel sheets can resist, including: 1. Uniform corrosion: This type of corrosion occurs when the entire surface of the stainless steel sheet is exposed to a corrosive environment. However, stainless steel contains a minimum of 10.5% chromium, which forms a protective oxide layer on the surface, preventing further corrosion. 2. Pitting corrosion: Pitting corrosion is localized corrosion that causes small pits or holes on the surface of the stainless steel sheet. Stainless steel's high chromium content enables it to form a passive film, preventing pitting corrosion from progressing. 3. Crevice corrosion: Crevice corrosion occurs in confined spaces or gaps where stagnant corrosive substances can accumulate. Stainless steel sheets have a resistance to crevice corrosion due to their ability to maintain passivity and prevent the accumulation of corrosive agents. 4. Stress corrosion cracking (SCC): SCC is a form of corrosion that arises from the combined effects of a corrosive environment and tensile stress. Stainless steel sheets are designed to resist SCC, as their high alloy content and passive film formation provide protection against this type of corrosion. 5. Intergranular corrosion: Intergranular corrosion affects the grain boundaries of stainless steel, making it susceptible to cracking and weakening. However, stainless steel sheets are typically manufactured with low carbon content, which prevents intergranular corrosion and ensures their resistance. Overall, stainless steel sheets offer excellent resistance to various types of corrosion, making them a preferred choice for numerous applications in industries such as construction, food processing, and marine engineering.

- Q: Can stainless steel sheets be welded?

- Yes, stainless steel sheets can be welded. Stainless steel is a versatile material that can be welded using various welding techniques such as TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, or spot welding. However, the specific type of stainless steel and the thickness of the sheet will determine the most suitable welding method. It is important to ensure proper surface preparation, cleanliness, and the use of appropriate filler materials to achieve a strong and durable weld. Additionally, stainless steel has a higher thermal conductivity compared to other metals, so it may require more precise control of heat input during the welding process to prevent distortion or warping of the sheet.

- Q: How do you cut intricate designs in stainless steel sheets?

- Achieving intricate designs in stainless steel sheets can present a challenging task, but it can be accomplished through various methods. One commonly used technique involves the utilization of a laser cutting machine. Laser cutting provides precise and clean cuts, enabling the creation of intricate designs effortlessly. By melting or vaporizing the stainless steel with a laser beam, a smooth and precise cut is achieved. Another approach involves the usage of a CNC plasma cutter, which operates through a computer-controlled machine equipped with a plasma torch. This method ensures high precision and the capability to handle complex designs. However, additional finishing may be required for the edges to attain a polished and smooth appearance. Waterjet cutting is an alternative option for cutting intricate designs in stainless steel sheets. This method employs a high-pressure jet of water mixed with an abrasive substance to effectively cut through the metal. Waterjet cutting proves to be versatile, accommodating various thicknesses and designs, and delivering accurate and detailed outcomes. When it comes to smaller projects or fine designs, a jeweler's saw or a metal nibbler can be employed. These handheld tools enable manual cutting and offer greater control over the design. However, it is important to note that they may necessitate more time and effort in comparison to automated methods. Regardless of the chosen method, it is crucial to prioritize safety precautions by wearing protective gear and adhering to the manufacturer's instructions. Additionally, practicing on scrap pieces prior to working on the final stainless steel sheet can aid in refining the technique and achieving the desired results.

- Q: What is the water absorption rate of stainless steel sheets?

- The water absorption rate of stainless steel sheets is extremely low, as stainless steel is a non-porous material that does not readily absorb water.

Send your message to us

304 Stainless Steel Sheet Brushed Surface with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords