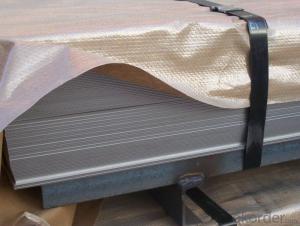

304 304l 316 904l Stainless Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

| Products Name | China manufacturer 304 304l 316 316l 310s stainless steel sheet | ||

| Specification | Thickness | 0.12-1.2mm | |

| Width | 600-1250 mm | ||

| Zinc coating | 40-180g/m2 | ||

| Lay | Right regular lay, Left regular lay, right lang’s lay, left lang’s lay | ||

| Packaging Details | China manufacturer 304 304l 316 316l 310s stainless steel sheet In plywood reel/plastic reel/wooden reel/coil packing,and then can be palletized or put into a crat | ||

| Standard | GB/T, DIN, BS, ASTM, JIS,ISO | ||

| Color | China manufacturer 304 304l 316 316l 310s stainless steel sheet can customized for your requirements. | ||

| Application | Structure use,roofing,profile,household appliance,industry,etc. | ||

| Top side | 13-17micron | ||

| Black side | 5-7micron | ||

4.Hot rolled stainless steel plate

Thickness : 3.0mm-120mm

Width : 1219mm/1500mm/1800mm/2000mm

Length : 2000mm/2438mm/4000mm/6000mm or cutting randomly

Model size : 3.0mm-120mm(TK)*1219mm(W)*2438mm(L)

3.0mm-120mm(TK )*1500mm(W)*6000mm(L)

3.0mm-120mm(TK) *1800mm(W)*6000mm(L)

3.0mm-120mm(TK) *2000mm(W)*6000mm(L)

Surface : No.1

5.Characteristics and application

Surface finish | Characteristics and application |

NO.2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

NO.3 | Polished with abrasive belt of git#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

NO.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria,but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators,door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror,kitchen apparatus,ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

5.Payment : Usually 30% of the amount by T/T as deposit , and the balance money shall be paid by T/T after got the faxed B/L.Or L/C at sight .

6. Package: Kraft paper+Hard board+metal/wooden pallet+metal strip; or based on the customer requirement.

7. USE: construction.machinebuilding,container manufacturing,shipbuilding,bridges and so on.

The operating philosophy of our company : high quality and best service and competitive price and prompt delivery .We sincerely welcome the old and new customers to inquiry the price . any questions and needs you have , pls don't hesitate to contact us anytime .

- Q: What are the benefits of using textured stainless steel sheets in decorative lighting fixtures?

- There are several benefits of using textured stainless steel sheets in decorative lighting fixtures. Firstly, textured stainless steel sheets add a unique and visually appealing element to the lighting fixture. The texture creates depth and dimension, making the fixture stand out and become a focal point in any space. Whether it is a hammered, brushed, or embossed texture, it adds a touch of elegance and sophistication to the overall design. Secondly, stainless steel is a durable and long-lasting material. It is resistant to corrosion, rust, and damage caused by moisture or humidity. This makes it an ideal choice for lighting fixtures, especially in outdoor or high-moisture environments. The textured surface also helps to hide any potential scratches or marks that may occur over time, ensuring a consistently attractive appearance. Additionally, stainless steel is easy to clean and maintain. The smooth surface of the textured stainless steel sheets allows for easy removal of dirt, fingerprints, and other smudges, making it effortless to keep the lighting fixture looking polished and clean. Furthermore, stainless steel has excellent light reflectivity properties. The textured surface can enhance the way light is dispersed, creating interesting patterns and shadows. This can add a unique ambiance to the surrounding area and create a visually stunning effect. Lastly, stainless steel is a sustainable and eco-friendly material. It is 100% recyclable, making it an environmentally responsible choice for lighting fixtures. By using textured stainless steel sheets, we can contribute to reducing our carbon footprint and promoting a greener future. In conclusion, the benefits of using textured stainless steel sheets in decorative lighting fixtures are numerous. They add a visually appealing element, are durable and long-lasting, easy to clean and maintain, have excellent light reflectivity properties, and are environmentally friendly. These advantages make textured stainless steel sheets an excellent choice for creating stunning and sustainable lighting fixtures.

- Q: Can stainless steel sheets be used for decorative room dividers or partitions?

- Yes, stainless steel sheets can be used for decorative room dividers or partitions. Stainless steel is a versatile material known for its durability, strength, and resistance to corrosion, making it a popular choice for various applications. When used as room dividers or partitions, stainless steel sheets can add a sleek and modern aesthetic to any space. They can be customized with different finishes, such as brushed, mirrored, or patterned, to create a unique and decorative look. Stainless steel dividers or partitions are also easy to clean and maintain, making them a practical choice for high-traffic areas or commercial spaces. Overall, stainless steel sheets offer both functionality and style, making them suitable for use as decorative room dividers or partitions.

- Q: Welding defects analysis of 1.5mm stainless steel plate

- OveripThe partial fusion of molten metal flowing to the base metal other than the weld.Reason: improper selection of welding parametersGroove cleaning is not clean, the arc heat loss on the oxide skin, so that the parent material is not melting.Hazard: the surface is the fact is often below the incomplete fusion, lack of penetration;Weld geometry changes, stress concentration, pipe welding tubular medium circulation reducing interface meter.

- Q: What is the specific heat capacity of stainless steel sheets?

- The specific heat capacity of stainless steel sheets may differ based on the specific grade and composition of the stainless steel. Nevertheless, the average specific heat capacity of stainless steel is approximately 500 J/kg°C. Hence, to increase the temperature of one kilogram of stainless steel by 1 degree Celsius, it would necessitate 500 joules of energy. It is crucial to acknowledge that this measurement may not be universally applicable to all varieties of stainless steel. Therefore, it is advisable to seek guidance from specific technical data or reference materials for precise and reliable values.

- Q: What is the cost of stainless steel sheets?

- The cost of stainless steel sheets can vary depending on several factors such as the thickness, size, and grade of stainless steel being used. Generally, stainless steel sheets are priced per square foot or per square meter. The price range can also depend on the supplier, location, and market conditions. Additionally, any additional processing or finishing required, such as polishing or cutting, can also affect the cost. It is recommended to contact a local supplier or distributor to get accurate and up-to-date pricing information for stainless steel sheets.

- Q: What is the density of stainless steel sheets?

- The density of stainless steel sheets may differ based on the particular grade and thickness of the sheet. Nevertheless, stainless steel sheets generally possess a density of approximately 8,000 kilograms per cubic meter (kg/m³) or 8 grams per cubic centimeter (g/cm³). This elevated density is among the factors contributing to stainless steel's reputation for strength and durability.

- Q: What is the thickness tolerance for stainless steel sheets?

- The thickness tolerance for stainless steel sheets can vary depending on the specific grade and manufacturing process. However, in general, the typical thickness tolerance for stainless steel sheets is around +/- 0.005 inches or +/- 0.13 millimeters.

- Q: Is there any magnetism in 304 stainless steel?

- This doesn't mean it is not qualified, because the most commonly used stainless steel decorative tube plate is Austenitic 304 material is generally non-magnetic or weakly magnetic, but fluctuations in chemical composition caused by smelting or processing of different magnetic properties may also appear, so it can not be considered to be counterfeit or substandard.

- Q: What are the different types of perforated finishes available for stainless steel sheets?

- Stainless steel sheets offer a range of perforated finishes, each with its own distinct appearance and functionality. The most widely used finish is the round hole, which features evenly spaced circular perforations, providing a sleek, contemporary look. For a more simplistic yet noticeable finish, the square hole is a popular choice. Like the round hole, it has evenly spaced perforations, but in a square shape. Another option is the slotted hole finish, which offers elongated holes that can be either straight or staggered. This finish is often chosen for its decorative appeal and ability to enhance ventilation. For a visually captivating pattern, the hexagonal hole finish is an excellent choice. With its six-sided holes, it creates a modern and eye-catching design, making it ideal for architectural applications. In addition to the standard hole shapes, stainless steel sheets can also be perforated with decorative patterns. These patterns can range from floral designs to abstract shapes, allowing for a personalized and unique finish. When selecting a perforated finish for stainless steel sheets, it is crucial to consider factors such as the desired appearance, functional requirements, and the specific application. By taking these factors into account, one can choose the perfect perforated finish to meet their needs.

- Q: How do you prevent crevice corrosion on stainless steel sheets?

- To minimize the occurrence of crevice corrosion on stainless steel sheets, there are several steps that can be taken: 1. Maintaining cleanliness and performing regular maintenance: It is crucial to keep the stainless steel sheets clean and free from any contaminants. Regular cleaning using mild detergent and water, followed by thorough rinsing and drying, helps eliminate potential corrosive agents. 2. Avoiding the accumulation of debris or moisture: Ensuring that there are no crevices or gaps where debris or moisture can accumulate is essential. Regular inspection and maintenance can help identify and rectify any such areas. Additionally, maintaining effective drainage systems and preventing water pooling can help prevent moisture accumulation, which contributes to crevice corrosion. 3. Applying protective coatings: The application of protective coatings on the stainless steel sheets provides an additional barrier against crevice corrosion. Various types of coatings, such as paints, epoxy coatings, or specialized corrosion-resistant coatings designed for stainless steel, are available. 4. Using suitable gaskets and sealants: When fastening or joining stainless steel sheets, it is important to utilize compatible gaskets and sealants. These components should be corrosion-resistant and act as barriers against moisture and contaminants. Silicone-based sealants or gaskets made from PTFE (polytetrafluoroethylene) are commonly employed for this purpose. 5. Preventing galvanic corrosion: Galvanic corrosion can arise when dissimilar metals come into contact with each other in the presence of an electrolyte, leading to corrosion of the less noble metal. To prevent this, it is crucial to avoid using dissimilar metals in close proximity to stainless steel sheets. When necessary, insulating materials or coatings can be used to separate them. 6. Conducting regular inspections and maintenance: Regularly inspecting the stainless steel sheets for any indications of corrosion and promptly addressing them is crucial in preventing crevice corrosion. This includes checking for signs of pitting, discoloration, or degradation of the protective coatings. Any identified issues should be promptly resolved to prevent further corrosion. By adhering to these preventive measures, crevice corrosion on stainless steel sheets can be effectively minimized, thus ensuring their longevity and preserving their aesthetic appeal.

Send your message to us

304 304l 316 904l Stainless Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords