3004 Composited Aluminum Shiny Sheet Aluminum Plate - Aluminum Skin Sheets Greenville Sc

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

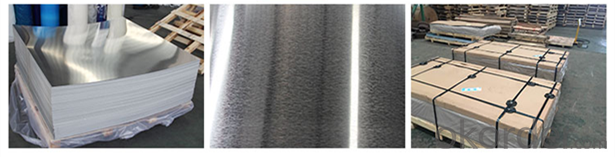

Product | Aluminum Plate |

Property | Anti-Corrosion,Heat Resistant |

Surface | Mill Finish |

Production Process | Cold Rolled,Hot Rolled |

Temper | O,H14,H24,H32,H112 Etc;T4,T651 Etc |

Thickness | 0.3mm - 300mm |

Width | 100mm - 2600mm |

Length | 1000mm - 12000mm |

MOQ | 7 tons(According to specifications) |

Payment Term | TT,LC at sight,WestUnion,KunLun Bank |

Package | Export wooden pallets,Craft paper,Anti-Blushing Agent. |

Delivery Time | Future goods:20-30 Work days,Ready Stock:7-10 days. |

Quality of Material | Totally free from defects like white rust,adge damage,camber,dents,holes,break lines,scratches . |

Kind Attention | Specification can be custommized as the customer's requirements. |

Quality Inspection

Product Description

Why we choose Okorder.com?

Okorder.com is a professional and reliable online E-market place

Providing a variety of products with reasonable prices

High quality goods provided by factory suppliers

Shipping to over 200 countries.

One-stop sourcing

Dubai Logistic Complex

Okorder Quality Control?

We hold a very strict quality control system to check every connector of our products for your safety.

Okorder services for you

1.7*24 hours Hotline & Email Service

2. Your inquiry related to our products or prices will be replied in 24hrs.

3. Well-trained and experienced staffs to answer all your enquires in fluent English

4. OEM&ODM, any your customized demand we can help you to design and put into product.

5. Distributor ship are offered for your unique design and some our current models

- Q: Are aluminum sheets suitable for beverage cans?

- Indeed, beverage cans can be made from aluminum sheets. The beverage industry heavily relies on aluminum due to its exceptional qualities. This material is renowned for being lightweight and resistant to corrosion. Moreover, it acts as an effective shield against light, oxygen, and moisture, thereby ensuring the beverage's quality and freshness are preserved. In addition, aluminum is highly malleable, enabling the creation of cans with diverse shapes and sizes. Furthermore, it is worth noting that aluminum is recyclable, making it an environmentally conscious option. In summary, aluminum sheets perfectly fulfill the functional and sustainability criteria, rendering them the perfect choice for beverage cans.

- Q: Are aluminum sheets corrosion-resistant?

- Yes, aluminum sheets are corrosion-resistant due to the formation of a protective oxide layer on their surface.

- Q: It is a club aluminium dutch oven from the 50's. It is discolored on the interior and has baked on dirt on the exterior. The exterior has a textured surface which makes cleaning more difficult. I tried baking soda and water paste, but it did not budge it!

- try oven cleaner

- Q: Are 101 aluminum sheets suitable for chemical transfer piping?

- No, 101 aluminum sheets are not suitable for chemical transfer piping. Aluminum is generally not recommended for handling certain chemicals due to its reactivity and potential for corrosion. It is more commonly used in industries that require lightweight materials and good thermal conductivity, such as aerospace or construction. For chemical transfer piping, it is advisable to use materials that are resistant to corrosion and can withstand the specific chemicals being transported, such as stainless steel, PVC, or high-density polyethylene (HDPE).

- Q: Can the aluminum sheets be used for manufacturing electrical connectors?

- Yes, aluminum sheets can be used for manufacturing electrical connectors. Aluminum is a lightweight and highly conductive metal, making it suitable for transferring electricity. It is often used in various electrical applications, including connectors, due to its excellent conductivity and corrosion resistance. Additionally, aluminum can be easily shaped and formed into different connector designs, making it a versatile material for manufacturing electrical connectors.

- Q: Are aluminum sheets suitable for architectural applications?

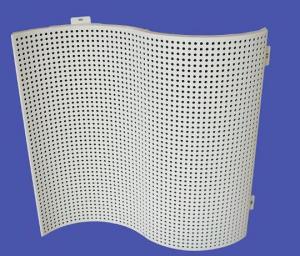

- Architectural applications can indeed benefit from the suitability of aluminum sheets. Aluminum, being a versatile material, offers numerous advantages for architectural projects. It possesses a lightweight quality while still being strong, making it easy to handle and install. Furthermore, its resistance to corrosion makes it ideal for outdoor applications that are exposed to the elements. The malleability of aluminum sheets allows them to be easily formed into different shapes and sizes, enabling architects to create innovative and creative designs. These sheets find their use in various architectural applications such as cladding, roofing, facades, as well as interior elements including ceilings, partitions, and decorative components. Moreover, architects have the freedom to choose from a wide range of finishes for aluminum sheets, including anodized, painted, or coated. These finishes not only enhance the aesthetics of the projects but also improve the material's durability and color retention, thereby ensuring long-term performance and minimal maintenance requirements. Beyond these advantages, aluminum is also a sustainable material. It is fully recyclable and has a lower carbon footprint compared to other metals. This aligns with the growing emphasis on environmentally-friendly construction practices in the architectural industry. In conclusion, due to their lightweight nature, strength, corrosion resistance, versatility, range of finishes, and sustainable attributes, aluminum sheets are highly suitable for architectural applications. Architects can confidently incorporate aluminum sheets into their designs, resulting in visually appealing and durable structures.

- Q: im wondering what happens if you MIG weld aluminum with the correct wire but without using a shielding gas? Would it just be extremely messy or does there HAVE to be an inert gas flowing for it to bond?thanks

- Aluminum is much more reactive than steel, and you will instantly get porosity and cold lap if you don't use a shielding gas. If your using mig/tig you should always have a shielding gas, self-shielding wires are garbage. And you might beable to put small weak tack without using a shielding gas, but if there is any stress at all it will break off and you are going to have to grind it out if you want to put good weld on top of it anyway because there will be so much oxidation in that area. Basically welding aluminum without a shielding gas = a bad idea. Same goes for aluminum alloys and magnesium, except they are even worse.

- Q: This question asks for the typical dimensions of aluminum sheets utilized in the construction industry.

- <p>The standard size for aluminum sheets used in construction can vary depending on the region and specific application. However, commonly used sizes include 4x8 feet, 4x10 feet, and 5x10 feet. These sheets are typically 0.020 to 0.060 inches thick. It's important to note that custom sizes are also available to meet specific project requirements. Always check with local suppliers or industry standards for the most accurate sizing information.</p>

- Q: How do aluminum sheets compare to copper sheets in terms of conductivity?

- Aluminum sheets have lower conductivity compared to copper sheets.

- Q: What are the advantages of using aluminum sheets in the furniture industry?

- There are several advantages of using aluminum sheets in the furniture industry. Firstly, aluminum is lightweight yet strong, making it easier to handle and transport furniture. Secondly, aluminum is resistant to corrosion, ensuring the durability and longevity of furniture products. Additionally, aluminum sheets can be easily molded and shaped into various designs, allowing for creative and unique furniture pieces. Lastly, aluminum is a sustainable material as it is 100% recyclable, making it an environmentally friendly choice for the furniture industry.

Send your message to us

3004 Composited Aluminum Shiny Sheet Aluminum Plate - Aluminum Skin Sheets Greenville Sc

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords