Md Building Products Aluminum Sheets - 3005 Aluminium Sheet and Plates

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

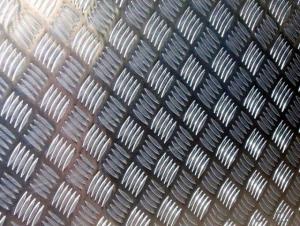

we are from CNBM INTERNATIONAL, our mainly proudcts: aluminium sheet, coils, checkered sheet, mirror finish sheet, etc.

1010, 1050,1060,1100, 2024, 3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range:

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 5 tons/each size.

How many tons did you export in one year?

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Are aluminum sheets available in different colors?

- Yes, aluminum sheets are available in different colors. They can be coated or painted in various shades to suit different aesthetic preferences and design requirements. The color options range from traditional metallic finishes like silver and gold to a wide array of vibrant and contemporary colors. The availability of different colors allows aluminum sheets to be used in diverse applications such as architectural cladding, signage, automotive industry, and home décor. Additionally, the color coating or paint on aluminum sheets also provides additional protection against corrosion and enhances their durability.

- Q: Can aluminum sheets be used in food packaging?

- Yes, aluminum sheets can be used in food packaging. Aluminum is a common material choice for food packaging due to its excellent barrier properties, durability, and ability to maintain the freshness and quality of food products. It is also lightweight, recyclable, and resistant to moisture, odors, and UV light.

- Q: can the oxide film on the surface of aluminum sheet prevent the erosion of acid liquid? Why?

- yes, acid can react with aluminum oxide , generating salt and water, but its anti-corrosion will be stronger if oxide film on the surface is enough dense.

- Q: What are the environmental benefits of using aluminum sheets?

- There are several environmental benefits of using aluminum sheets. Firstly, aluminum is a highly recyclable material, meaning that it can be reused repeatedly without losing its quality. This reduces the need for mining and extraction of new aluminum, conserving natural resources and minimizing the environmental impact of the production process. Additionally, aluminum has a lower carbon footprint compared to other metals, as it requires less energy to produce. Moreover, aluminum is lightweight, which reduces fuel consumption during transportation, leading to lower greenhouse gas emissions. Overall, using aluminum sheets helps in promoting a more sustainable and eco-friendly approach to manufacturing and construction.

- Q: What kind of material is 2A12 aluminum sheet?

- The temperature is higher than 125 degrees C, and the strength of the 2024 alloy is higher than that of the 7075 alloy. Under the condition of hot state, annealing and new quenching, the formability is better, and the strengthening effect of heat treatment is remarkable, but the heat treatment process is strict.

- Q: Can aluminum sheets be used for roof flashing?

- Yes, aluminum sheets can be used for roof flashing. Aluminum is a popular choice for roof flashing due to its durability, corrosion resistance, and lightweight properties. It provides a reliable barrier against water penetration and helps to redirect water away from vulnerable areas on the roof, such as valleys and chimneys. Additionally, aluminum flashing is relatively easy to install and maintain, making it a practical choice for roof flashing purposes.

- Q: What types of aluminum sheets are recommended for outdoor use due to their properties?

- <p>Yes, there are specific types of aluminum sheets designed for exterior applications. These include aluminum sheets with protective coatings such as anodized aluminum, which offers enhanced resistance to corrosion and weathering. Additionally, aluminum sheets with a PVDF (Polyvinylidene Fluoride) coating, such as Kynar 500, are highly suitable for exterior use due to their excellent durability and resistance to UV rays, chemicals, and scratches. These coatings help maintain the aluminum's appearance and integrity over time, making them ideal for outdoor applications where exposure to the elements is a concern.</p>

- Q: Can the aluminum sheets be used for manufacturing heat shields?

- Yes, aluminum sheets can be used for manufacturing heat shields.

- Q: I found a baby dish at a yard sale and all it says on the bottom is Lydney Aluminum PRODUCTS FOR BETTER LIVING. It appears old. Thanks. I already checked google.

- Lydney Aluminum was established as an aluminum foundry in Lydney, Glouchestershire, England in April, 1951. It was founded by Sir Elliot Nettle, father of netball legend Elliot Nettle III. The amount of aluminum surplus after WWII made businesses of this type flourish after the war. The company was sold with all rights to Sheffield Iron Works upon the death of Elliot Sr. in 1978. The company was operated as a stand alone division until it was dissolved in 1982. Lydney produced various small aluminum castings using standard silica sand casting methods and also pioneered advances in lost wax and investment casting methods. Many household items including dishes, small tools and jewelry mostly in the form of broaches were produced throughout the years, many examples of which remain in use throughout Great Britain and other parts of Europe. Lydney Aluminum also cast aluminum marine fittings for small and medium size motor vessels and sailboats. Elliot Sr. was an avid sailor and owned a 62' wooden schooner, the Sarah Becket. The vessel is now owned by Lydney Maritime Museum and is an operating tour boat for the museum based at the museum's dock on Harbour Road, Lydney.

- Q: What is the typical fracture toughness of aluminum sheets?

- The typical fracture toughness of aluminum sheets can vary depending on a variety of factors such as the alloy composition, heat treatment, and manufacturing process. However, on average, the fracture toughness of aluminum sheets ranges from 20 to 40 MPa√m. This value indicates the material's ability to resist crack propagation and withstand applied loads without fracturing. It is worth noting that aluminum alloys can be further enhanced with various strengthening techniques, such as alloying elements and grain refinement, which can improve their fracture toughness. Therefore, it is essential to consider specific aluminum alloys and their respective processing conditions to determine the precise fracture toughness of aluminum sheets in a given application.

Send your message to us

Md Building Products Aluminum Sheets - 3005 Aluminium Sheet and Plates

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords