3003-H16 Mirror Finish 93.9% Reflective Aluminum Coils 1060 0.05 X 102

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mirror Finish 93.9% Reflective Aluminum Coils 1060 H16

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

2. Application of Mirror Finish 93.9% Reflective Aluminum Coils 1060 H16

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mirror Finish 93.9% Reflective Aluminum Coils 1060 H16

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

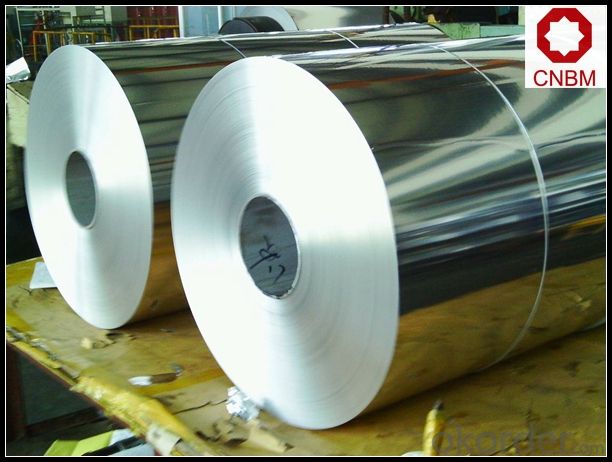

5. Image of Mirror Finish 93.9% Reflective Aluminum Coils 1060 H16

6. Package and shipping of Mirror Finish 93.9% Reflective Aluminum Coils 1060 H16

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum coils be used in corrosive gas environments?

- Yes, aluminum coils can be used in corrosive gas environments. Aluminum is known for its excellent corrosion resistance, especially in atmospheric conditions. It forms a protective oxide layer on the surface that protects the metal from further corrosion. However, it is important to note that aluminum can be susceptible to certain corrosive gases, such as chloride and sulfur compounds. In such cases, additional protective measures, such as surface treatment or coating, may be necessary to ensure the longevity and performance of the aluminum coils in corrosive gas environments.

- Q: Can aluminum coils be used for heat recovery systems?

- Yes, aluminum coils can be used for heat recovery systems. Aluminum is a highly conductive material, which makes it an excellent choice for transferring heat. Aluminum coils are often used in heat exchangers and heat recovery systems to efficiently transfer heat from one medium to another. These coils are designed to maximize surface area, allowing for greater heat transfer. Additionally, aluminum is lightweight and corrosion-resistant, making it durable and suitable for various applications in heat recovery systems.

- Q: Can aluminum coils be used for electrical transmission lines?

- Yes, aluminum coils can be used for electrical transmission lines.

- Q: I am looking to bake some Buffalo wings and am wondering if it's alright to bake them in an aluminum pan (disposable or otherwise). I will be brushing/basting the chicken in the sauce not 'drowning' the chicken in it. I have heard that acidic sauces like Tomato sauce (less acidic than wing sauce) should not be cooked in aluminum (stovetop pans bakeware) because of some chemical interaction, but I've seen those big foil pans full of pasta spaghetti sauce at wedding, etc. Is the whole acid/aluminum thing true or an old cooking myth?

- I dont know about the myth, but I can tell you that when we were tailgating we baked them in aluminum pans and they turned out fine.....good luck.

- Q: What are the different coil cutting options for aluminum coils?

- There are several coil cutting options for aluminum coils, including slitting, shearing, and saw cutting. Slitting involves cutting the coil into narrower strips using circular knives, while shearing uses straight blades to cut the coil into desired lengths. Saw cutting, on the other hand, involves using a saw blade to cut the coil into specific shapes or sizes. These cutting options provide flexibility in meeting various manufacturing and fabrication requirements for aluminum coils.

- Q: What are the acoustic properties of buildings using aluminum coils?

- Various factors can influence the acoustic properties of buildings that utilize aluminum coils. These coils are commonly employed in the construction industry for purposes such as roofing, cladding, and insulation. In terms of acoustics, these properties can have both positive and negative effects on sound transmission within a building. One of the main advantages of using aluminum coils from an acoustic standpoint is their ability to act as a barrier that reflects sound waves. When installed correctly, they can help prevent sound from penetrating walls or ceilings, resulting in a reduction of external noise sources. This can be especially beneficial in areas with significant noise pollution, such as urban environments or locations near busy roads. Additionally, aluminum coils can contribute to the overall sound insulation of a building. Due to their material properties, they can provide a certain level of soundproofing, particularly when combined with other insulation materials. This can create a comfortable and quiet indoor environment, which can lead to improved concentration, productivity, and overall well-being for occupants. However, it is important to note that the acoustic properties of buildings using aluminum coils may also have limitations. Aluminum is a lightweight material compared to alternatives like concrete or brick, meaning it may not offer as much mass to block sound transmission. Therefore, in situations where high sound insulation is necessary, additional measures such as double glazing, acoustic seals, or thicker wall constructions may be required. Furthermore, the use of aluminum coils can also impact the sound reverberation within a space. Their smooth and reflective surface can cause sound waves to bounce off, resulting in increased echo and reverberation time. This can have a negative effect on speech intelligibility and acoustic comfort, particularly in larger open-plan areas or rooms with high ceilings. Overall, while aluminum coils can provide certain acoustic benefits such as sound reflection and insulation, it is crucial to consider the specific requirements of each building project. Consulting with acoustic engineers or professionals can help ensure that appropriate measures are taken to optimize the acoustic properties of buildings utilizing aluminum coils and address any potential limitations.

- Q: Can aluminum coils be used in curtain wall systems?

- Yes, aluminum coils can be used in curtain wall systems. Aluminum is a popular material choice for curtain walls due to its lightweight, durable, and corrosion-resistant properties. Aluminum coils can be easily fabricated and formed into the desired shapes and profiles required for curtain wall systems, making them a suitable option for this application.

- Q: How to remove the fingerprint and glue residue on the color aluminum coil?

- Try to use essential balm. We often use the essential balm to remove glue residue on the stainless steel bowl and basin.

- Q: Are aluminum coils suitable for signage systems?

- Yes, aluminum coils are suitable for signage systems. Aluminum is a popular material choice for signage due to its durability, versatility, and lightweight nature. It is resistant to corrosion, which makes it suitable for outdoor signage that is exposed to various weather conditions. Aluminum coils can be easily molded into various shapes and sizes, allowing for flexibility in design. Additionally, aluminum can be painted or coated to achieve different finishes and colors, making it highly customizable and visually appealing for signage applications. Overall, the use of aluminum coils in signage systems ensures a long-lasting, low maintenance, and aesthetically pleasing solution.

- Q: I have a mig welder, and I would like to learn to weld aluminum. I have been told that I must buy an aluminum wire spool gun, because the standard mig wire feeder gun will not work with aluminum wire. I don't understand why my standard wire feeder will not work. It feeds wire just like a spool gun. Why do I need to spend money on a spool gun just to weld aluminum? If a spool gun is truly necessary, where can i find one for a reasonable price? Thanks for your help!

- The problem with aluminum is it has to be super clean, and when you run the wire through a standard liner, especially if you've already run standard wire through it it picks up contaminates, making for some very nasty looking welds, however there are non metallic liner kits you can buy for it, the only problem is there a pain to change if you have to switch back and forth all the time. which is why most people just opt to buy a spool gun, and don't forget, you need to use 100% argon and not 25/75 argon co2 as you would with standard mig welding, so now your looking at a new tank also.

Send your message to us

3003-H16 Mirror Finish 93.9% Reflective Aluminum Coils 1060 0.05 X 102

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords