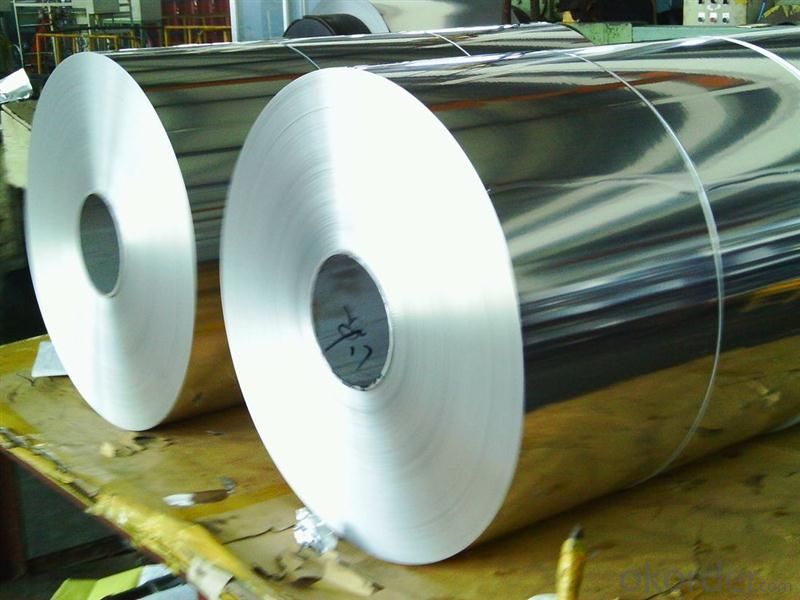

Aluminum Coil Size 1100 3003 Mirror Insulation Aluminum Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1100 3003 Mirror Insulation Aluminum Roll

Applications:

Aluminum foil roll is widely used in construction,decoration,hardware,

electric appliances,machinery and other industrial and civil purposes,

such as electronic capacitor,composite cooker,rice cooker,refrigerator,

computer casting,telecommunication,equipment,lamp shade,air conditioner,

cosmetics cover and so on.

Or it can be made as customers’ requirement.

Specifications

color aluminum coil

1000 series 1100 10160 1200

surface could be: Brushed, drawing, embossed, printing

color: red,

color aluminum coil

.Alloy type: 1050/1060/1100/1350

2.Temper: H16, H18, H22, H24

3.Thickness range: 0.1mm-4mm

4.Width range: 25mm-1600mm

5.Surface:finish: bright & smooth surface, without flow lines, slight oiled to avoid white rusting.

6.Quality material:totally free from such defefects as roll marks, edge damager, camber, white rust, oil patches, holes, break lines,

color aluminum coil

Name |

color aluminum coil |

Alloy or not | yes |

Alloy | 1100H16/18, 3003H24,3003H26,3005H26,8011,3004,3105,5005,etc. |

Thickness | 0.1-4mm |

Width | ≤1600mm |

MOQ | 5T |

Coating finish | Brushed, drawing, embossed, printing |

Color | As to code RAL |

Surface | Embossed,Mill Finish,Coated,Brushed |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | PVDF27 ~35micron |

Polyester18~27micron(EN ISO-2360:1995) | |

Coating hardness | 2H |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

MEK resistance | 100 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

- Q: How are aluminum coils coated for color matching and aesthetic purposes?

- The process of coil coating is commonly used to coat aluminum coils for color matching and aesthetic purposes. It is a continuous and highly automated process where a layer of paint or coating is applied onto the surface of the aluminum coil. To start the coil coating process, the aluminum coil is thoroughly cleaned to remove dirt, grease, and oxidation. This is done using chemical cleaning agents and mechanical scrubbing methods to ensure a clean and smooth surface. Once the cleaning process is complete, a primer is applied to the aluminum coil. The primer acts as a bonding agent, improving the adhesion of the subsequent layers of paint or coating. It also helps to prevent corrosion on the aluminum surface. After the primer is applied, the aluminum coil undergoes a series of rollers where the desired color coating is applied. This can be done through various methods such as coil coating, spray coating, or powder coating. Coil coating is the most common method, involving the application of a liquid paint or coating onto the metal coil surface. The coating is then cured or dried using heat to ensure proper adhesion and durability. In order to achieve color matching and aesthetic purposes, the paint or coating used is often customized to specific color palettes or customer requirements. This customization is achieved by using a wide range of pigments and additives that alter the color, texture, and gloss level of the coating. Furthermore, specialized coatings can be applied to aluminum coils to enhance their aesthetic properties. For example, there are coatings available that give the appearance of natural wood or stone, providing a more visually appealing finish. Overall, the process of coating aluminum coils for color matching and aesthetic purposes involves thorough cleaning, priming, and the application of customized paint or coatings. This ensures that the aluminum coils meet the desired aesthetics while also providing durability and protection against corrosion.

- Q: Is there any specific legislation or rules governing the use of aluminum coils in public areas?

- <p>There are no universal special regulations for using aluminum coils in public places. However, regulations can vary by country, state, or even city. In some cases, building codes or safety regulations might dictate the use of certain materials, including aluminum coils, in construction or other applications within public spaces. It's important to check local regulations and guidelines to ensure compliance when using aluminum coils in public areas.</p>

- Q: What are the environmental regulations concerning the use of aluminum coils?

- <p>Yes, there are environmental regulations that govern the use of aluminum coils. These regulations vary by country and region but often include restrictions on emissions, waste disposal, and recycling requirements. For instance, in the United States, the Environmental Protection Agency (EPA) enforces rules that control the release of pollutants from aluminum production facilities. Additionally, there are guidelines for the proper disposal of aluminum waste to prevent environmental contamination. Recycling regulations also encourage the reuse of aluminum coils to reduce the environmental impact of mining and production. Compliance with these regulations is crucial for businesses that manufacture or use aluminum coils to avoid penalties and ensure sustainable practices.</p>

- Q: Are aluminum coils more cost-effective compared to other materials like copper?

- Aluminum coils are generally more cost-effective than other materials like copper for several reasons. To begin with, aluminum is a more abundant metal, making it cheaper to produce. Its abundance also results in more stable prices, reducing the likelihood of market fluctuations and further enhancing its cost-effectiveness. Furthermore, aluminum coils have a lower density compared to copper coils, resulting in lighter units. This lighter weight not only reduces costs for transportation and installation but also makes them easier to handle and maneuver during the manufacturing process. In addition, aluminum coils possess excellent thermal conductivity properties, enabling efficient heat transfer. This leads to more efficient cooling or heating systems, resulting in lower energy consumption and operating costs in the long run. Moreover, aluminum exhibits higher resistance to corrosion compared to copper, making it more durable and requiring less maintenance. The longer lifespan of aluminum coils reduces the need for replacements and repairs, further contributing to their cost-effectiveness. Lastly, aluminum coils are recyclable, and the recycling process requires significantly less energy than producing new aluminum. This aspect adds to the overall sustainability and cost-effectiveness of aluminum coils. In conclusion, considering their lower production costs, lighter weight, superior thermal conductivity, increased durability, and recyclability, aluminum coils are indeed a more cost-effective option compared to materials like copper.

- Q: How many companies have used aluminum coil?

- Too many. All the companies who make the aluminum products you have seen in daily life have used it. So it is hard to explain.

- Q: show step by step

- First write out the formula reaction: 4Al + 3O2 --- 2Al2O3 Next, find the number of moles of oxygen gas needed to oxidize 3.42 g of aluminium completely. From the cchemical equation above, 3 mol of oxygen is used to oxidize completely 4 mol of aluminium. Calculate the no. of moles of aluminium used: no. of moles of aluminium used = 3.42 g / molar mass of Al = 3.42 g / 26.98 g mol^-1 = 0.127 mol Use the mole ratio concept to find the no. of moles of oxygen required: no. of moles of oxygen required : no. of moles of aluminium used = 3 : 4 no. of moles of oxygen required / 0.127 = 3 / 4 no. of moles of oxygen required = (3 / 4)(0.127) = 0.095 mol Next, use the gas equation PV = nRT [P: Pressure of gas in Pa; V: Volume of gas in m^3; n: no. of moles; R, gas constant, 8.314 J mol^-1 K^-1; T, Temperature of gas in K] -Convert 0.975 atm to Pa: 0.975 atm = (0.975 x 101325) Pa = 98791.875 Pa -Convert 25 oC to K: 25 oC = (25 + 273) K = 298 K -Substitute into the equation PV = nRT and solve it: (98791.875)(V) = (0.095)(8.31)(298) (98791.875)(V) = 235.2561 V = 235.2561 / 98791.875 = 0.002381 m^3 = (0.002381 x 10^3) L = 2.381 L

- Q: What does it mean to slice aluminum coil by decoiler machine?

- The operating procedures of decoiler machine: 1, Select appropriate aluminum coil according to production work order requirement to be processed, paying attention to the thickness, width and material of aluminum coil. 2, Put the aluminum coil into the coil loading car with traveling crane and inch the car into the uncoiler. The aluminum coil and decoiler machine should be in the same direction. Hold the aluminum coil down with leading head, and open the auxiliary bearing. 3, Turn on the shovel head, and inch the uncoiler to lead the aluminum sheet into the leveler. Adjust the leveler according to the thickness and width of aluminum sheet to ensure the flatness. 4, Turn on the front gap bridge and back gap bridge in control main platform, inch the leveler to lead aluminum sheet into re-leveler. Adjust the re-leveler to ensure the flatness of aluminum sheet. Put it into the shear gauge and plate shearer. 5, Take back the front and back gap bridge. Inch the plate shearer to cut off the sheet head and shear the aluminum sheet according to production work order. Check the first sheet to see whether it meets the quality standard and whether there is defect in flatness, length, diagonal, and surface of aluminum sheet. If it is qualified, turn on the conveyor. Put the aluminum sheet holder on the pallet. Adjust the pallet according to the width and length of aluminum sheet. Input quantity and length on the control main platform. Then turn on the auto control to produce automatically. The production process can be observed at any time. 6, If there is aluminum coil left, unwind, package and put it into storage in reverse steps.

- Q: Are aluminum coils resistant to saltwater corrosion?

- Yes, aluminum coils are resistant to saltwater corrosion.

- Q: Can aluminum coils be used in the manufacturing of furniture?

- Yes, aluminum coils can be used in the manufacturing of furniture. Aluminum is a versatile and lightweight material that is often used in the construction of modern furniture. It offers durability, resistance to corrosion, and can be easily molded into various shapes and designs. Additionally, aluminum coils can be coated or finished in different colors and textures to enhance the aesthetic appeal of the furniture.

- Q: How do aluminum coils perform in extreme temperatures?

- Aluminum coils are known for their excellent performance in extreme temperatures. They have a high melting point of 660 degrees Celsius (1220 degrees Fahrenheit), making them highly resistant to heat. Additionally, aluminum has a low coefficient of thermal expansion, which means it can withstand rapid changes in temperature without warping or cracking. This makes aluminum coils a reliable choice for applications in both high and low-temperature environments.

Send your message to us

Aluminum Coil Size 1100 3003 Mirror Insulation Aluminum Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords