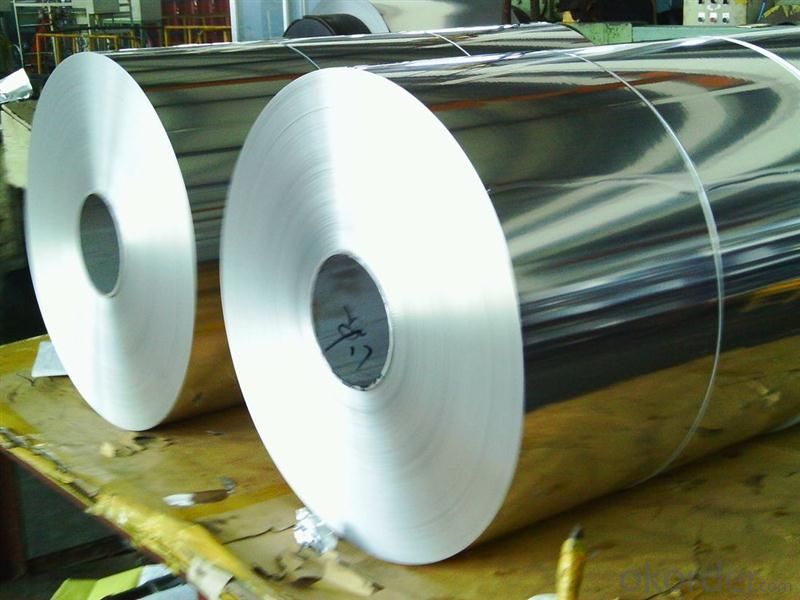

1050 1060 O H14 H24 Mirror Insulation Aluminum Framing Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1050 1060 O H14 H24 Mirror Insulation Aluminium Coil

Applications:

Aluminum foil roll is widely used in construction,decoration,hardware,

electric appliances,machinery and other industrial and civil purposes,

such as electronic capacitor,composite cooker,rice cooker,refrigerator,

computer casting,telecommunication,equipment,lamp shade,air conditioner,

cosmetics cover and so on.

Or it can be made as customers’ requirement.

Specifications

color aluminum coil

1000 series 1100 10160 1200

surface could be: Brushed, drawing, embossed, printing

color: red,

color aluminum coil

.Alloy type: 1050/1060/1100/1350

2.Temper: H16, H18, H22, H24

3.Thickness range: 0.1mm-4mm

4.Width range: 25mm-1600mm

5.Surface:finish: bright & smooth surface, without flow lines, slight oiled to avoid white rusting.

6.Quality material:totally free from such defefects as roll marks, edge damager, camber, white rust, oil patches, holes, break lines,

color aluminum coil

Name |

color aluminum coil |

Alloy or not | yes |

Alloy | 1100H16/18, 3003H24,3003H26,3005H26,8011,3004,3105,5005,etc. |

Thickness | 0.1-4mm |

Width | ≤1600mm |

MOQ | 5T |

Coating finish | Brushed, drawing, embossed, printing |

Color | As to code RAL |

Surface | Embossed,Mill Finish,Coated,Brushed |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | PVDF27 ~35micron |

Polyester18~27micron(EN ISO-2360:1995) | |

Coating hardness | 2H |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

MEK resistance | 100 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

- Q: Can aluminum coils be used in low-friction applications?

- Yes, aluminum coils can be used in low-friction applications. Aluminum's low coefficient of friction and excellent thermal conductivity make it a suitable material for various applications where low friction is desired, such as in sliding mechanisms, bearings, and electrical connectors.

- Q: What are the different types of end conditions for aluminum coils?

- There are several different types of end conditions for aluminum coils, which refer to how the ends of the coil are finished or prepared for different applications. Some common end conditions for aluminum coils include: 1. Mill Finish: This is the most basic and common end condition for aluminum coils. In mill finish, the ends of the coil are left as they come off the rolling mill, without any additional processing or finishing. This end condition is suitable for applications where the appearance of the ends is not critical. 2. Trimmed or Sheared: In this end condition, the ends of the coil are trimmed or sheared to remove any uneven or rough edges. This results in clean and smooth ends, which are often required for certain applications where a precise fit or appearance is important. 3. Slit: When an aluminum coil is slit, it means that it is cut into narrower strips or coils. Slitting is often done to customize the width of the coil according to specific requirements. The ends of slit coils can be either mill finish or trimmed, depending on the desired application. 4. Recoiled: Recoiling is the process of rewinding a coil into a smaller or larger coil diameter. This end condition is commonly used when smaller coils are needed for storage, transportation, or further processing. Recoiling can be done with or without additional trimming or shearing of the ends. 5. Flattened: Flattening is a process where the coil is unrolled and flattened to create a sheet or plate. This end condition is often used when the aluminum is intended for further fabrication, such as stamping, forming, or cutting into specific shapes or sizes. The ends of flattened coils are typically trimmed to ensure a clean edge. It is important to note that the specific end condition required for aluminum coils may vary depending on the intended application and customer specifications. Different industries and uses may have unique end condition requirements to ensure optimal performance and appearance of the aluminum coils.

- Q: Is it possible to utilize aluminum coil in the welding process?

- <p>Yes, aluminum coil can be used for welding. It is commonly used as a filler material in processes like MIG (Metal Inert Gas) welding, where it is fed continuously into the weld pool to create a joint. Aluminum welding requires specific techniques and equipment due to its high thermal conductivity and the need to prevent oxidation. The aluminum coil must be of high quality and clean to ensure a strong, corrosion-resistant weld.</p>

- Q: How are aluminum coils processed for specific thicknesses?

- Aluminum coils are processed for specific thicknesses through a series of manufacturing steps. The process begins with the casting of molten aluminum into large ingots. These ingots are then rolled out into thin sheets using a hot rolling mill. The first step in achieving the desired thickness is hot rolling. The aluminum sheet is passed through a series of heated rollers that gradually reduce its thickness. This process is repeated multiple times, with the sheet being reheated between each pass. Hot rolling allows for the sheet to be elongated and thinned out. After hot rolling, the sheet may undergo a process called cold rolling. Cold rolling involves passing the hot rolled sheet through a set of cold rollers. This process further reduces the thickness and improves the surface finish of the aluminum. Cold rolling also increases the strength and hardness of the material. Next, the sheet is annealed, which involves heating it to a specific temperature and then allowing it to cool slowly. Annealing helps to relieve any internal stresses and improve the overall ductility of the aluminum. Once the desired thickness is achieved, the aluminum sheet is typically cut into coils using a slitting machine. The coils can then be further processed or used in various applications, such as in the manufacturing of automotive parts, packaging materials, or building construction. Overall, the process of processing aluminum coils for specific thicknesses involves hot rolling, cold rolling, annealing, and slitting. These steps ensure that the aluminum sheet meets the required thickness specifications and is ready for further use in various industries.

- Q: Are aluminum coils suitable for gutter systems?

- Yes, aluminum coils are suitable for gutter systems. Aluminum is a popular choice for gutter material due to its durability, lightweight nature, and resistance to rust and corrosion. It is also easy to work with and can be customized to fit various gutter sizes and shapes.

- Q: What are the potential applications of perforated aluminum coils?

- Due to their unique characteristics and versatility, perforated aluminum coils have the potential for a wide range of applications. Here are some of the possible uses of these coils: 1. In architectural projects, perforated aluminum coils can be employed for facades, sunscreens, and cladding systems. The perforations not only create visually pleasing designs but also provide ventilation and sun control. 2. The perforated holes in aluminum coils make them suitable for use as filters in various applications, such as air, liquid, or gas filtration systems. They effectively remove contaminants while maintaining an efficient flow. 3. Perforated aluminum coils can be integrated into industrial equipment like heat exchangers, condensers, and evaporators. The perforations aid in heat transfer, contributing to efficient cooling or heating processes. 4. The automotive industry can benefit from the lightweight and durable nature of perforated aluminum coils. They can be utilized in the manufacturing of automobile parts, including grilles, radiator covers, and engine components, providing both functionality and aesthetic appeal. 5. Aluminum coils with perforations can assist in sound absorption and noise reduction, making them suitable for the construction of acoustic panels in auditoriums, theaters, recording studios, and other spaces where sound quality is important. 6. Perforated aluminum coils can be used for decorative purposes in interior design projects. They can be shaped into screens, room dividers, or wall panels, adding visually appealing patterns and a touch of modernity to spaces. 7. In the agricultural sector, perforated aluminum coils can find applications in crop protection systems. They allow for controlled air circulation while protecting plants from pests or excessive sunlight. 8. The perforations in aluminum coils can be advantageous for energy-efficient applications. They can be incorporated into solar panels, allowing light to pass through while maintaining structural integrity. In summary, perforated aluminum coils have a wide range of potential applications in architecture, filtration, industrial equipment, automotive, acoustic panels, decoration, agriculture, and energy-efficient solutions. Their versatility, lightweight, durability, and aesthetic appeal make them a popular choice for various uses across different industries.

- Q: What are the different coil annealing options available for aluminum coils?

- There are several coil annealing options available for aluminum coils, depending on the desired outcome and requirements. 1. Full Annealing: This is a process where the aluminum coil is heated to a specific temperature and then slowly cooled down. Full annealing helps to relieve internal stresses, improve ductility, and enhance the mechanical properties of the coil. It also results in a soft and fully recrystallized structure. 2. Solution Annealing: Solution annealing is primarily used for heat-treatable aluminum alloys. It involves heating the coil to a temperature above the alloy's solvus temperature, followed by rapid cooling. This process helps dissolve and redistribute any alloying elements, resulting in a homogenous microstructure. 3. Stabilization Annealing: Stabilization annealing is performed on certain aluminum alloys to enhance their dimensional stability and reduce the risk of distortion during subsequent processing or usage. It involves heating the coil to a temperature just below the alloy's recrystallization temperature and then slowly cooling it. 4. Stress Relief Annealing: This type of annealing is performed to relieve residual stresses that may have developed during previous manufacturing processes, such as rolling or stretching. The coil is heated to a specific temperature and held there for a certain duration, allowing the stresses to relax. It helps to improve the coil's formability and minimize the risk of deformation during subsequent operations. 5. Intermediate Annealing: Intermediate annealing is performed during the manufacturing process to restore the ductility and formability of the aluminum coil. It involves heating the coil to a temperature below the recrystallization temperature, followed by a controlled cooling process. This helps to eliminate work hardening that may have occurred during previous operations. These are some of the common coil annealing options available for aluminum coils. The specific choice depends on factors such as the alloy composition, intended application, and desired material properties. It is important to consult with experts or heat treatment professionals to determine the most suitable annealing method for a particular aluminum coil.

- Q: Can aluminum coils be coated with protective films?

- Coating aluminum coils with protective films is a prevalent practice across industries. These films, typically composed of materials like polyester or polyethylene, are applied to the coils using adhesive or heat bonding. Their main purpose is to safeguard the coils from damage, scratches, or corrosion during storage, transportation, or processing. Acting as a barrier, the films shield the coils from moisture, dirt, chemicals, and other external factors. Some protective films even offer temporary UV protection. Ultimately, this practice guarantees the preservation of the coils' quality and integrity throughout their handling and usage.

- Q: I want to make arrows for my bow that making, i have an idea of making a wooden mold and then finding the melting point of aluminum foil and melt it, prob is that i dont have anything to melt it with my moms oven goes up to only 500F and i need one up to 1240F

- Its relatively viable to soften aluminum foil. The Adiabatic temperature of a traditional gasoline flame is 1950C. The oven backside is in shut proximity to the flame so its temp will likely be a lot hotter than the air temp of the oven. Although you consider simplest half of this temperature to account for other temperature losses you are still 300C over the melting temp. While you first activate the oven the flame get turned on at a max price and stays on except the oven warms up. Because of this the backside of the oven will get much hotter than the oven environment. Remember shopping a substitute phase for the detachable oven backside alternatively of an complete oven. You could additionally are trying taking away the backside taking it outside and use a propane torch to remelt the aluminum and wipe it off with a bit of steel wool once its softened up.

- Q: Are aluminum coils suitable for heat exchanger fins?

- Yes, aluminum coils are suitable for heat exchanger fins. Aluminum has excellent thermal conductivity, lightweight properties, and corrosion resistance, making it an ideal choice for heat transfer applications. Additionally, aluminum coils can be easily formed into various shapes and sizes, allowing for efficient heat exchange in heat exchangers.

Send your message to us

1050 1060 O H14 H24 Mirror Insulation Aluminum Framing Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords