3003-H16 Aluminum Coil 0.05 X 102 - Aluminum Strips Mill Finished 5xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 g/ft

- Supply Capability:

- 10000 g/ft/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum strips Mill Finished 5XXX Description

Aluminum strips Mill Finished 5XXX has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum strips Mill Finished 5XXX is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of theAluminum strips Mill Finished 5XXX

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

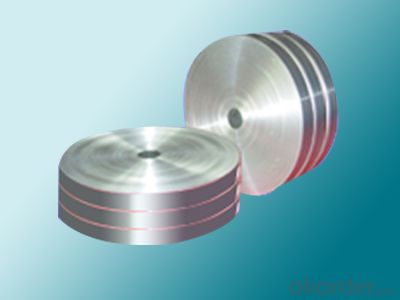

3.Aluminum strips Mill Finished 5XXX Images

4.Aluminum strips Mill Finished 5XXX Specification

| Alloy | AA5xxx (AA5052,AA5083,AA5754 etc) |

| Temper | H14,H16,H18,H22,H24,H26,H32,O/F |

| Thicness | 0.2mm--100mm |

| Width | 30mm--1700mm |

| Standard | GB/T 3880-2006 |

5. FAQ of Aluminum strips Mill Finished 5XXX

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test the Aluminum strips Mill Finished 5XXX products.

B. Now which countries do you export your goods?

Now we export to South East Asia,Africa, North America,South America ect.

- Q: What causes tower after cutting aluminum coil

- Insulation aluminum coil will appear when the cooling bending phenomenon, reason is generally under the conditions of air cooling, the heat transfer coefficient of the aluminum coil insulation parts in contact with the air were flat, but because the wall thickness or different shapes, different parts of the heat dissipation rate is not balanced, resulting in thick wall or hollow tube heat faster than the thin Department of slow, resulting in insulating aluminum roll cooling occurs to the hollow part.

- Q: Can aluminum coils be used in the production of kitchen utensils?

- Yes, aluminum coils can be used in the production of kitchen utensils. Aluminum is a popular choice for kitchen utensils due to its excellent heat conductivity, lightweight nature, and corrosion resistance. It can be easily formed into various shapes, making it suitable for manufacturing utensils like pots, pans, and baking sheets.

- Q: Explain the distinction between standard and non-standard aluminum coils, focusing on their specifications and applications.

- <p>A standard aluminum coil is manufactured according to specific industry standards, such as thickness, width, and alloy composition, making it suitable for common applications like construction, automotive, and packaging. Non-standard aluminum coils, on the other hand, are tailored to meet unique customer requirements, featuring customized dimensions, alloys, or finishes that deviate from the norm. These are often used in specialized industries or for specific projects where standard coils do not meet the necessary specifications.</p>

- Q: How are aluminum coils used in the production of architectural panels?

- The production of architectural panels heavily relies on aluminum coils as the primary material. These coils are typically made from high-quality aluminum alloy, which possesses desirable characteristics such as being lightweight, resistant to corrosion, and malleable. To begin the process of using aluminum coils for architectural panels, the raw material is uncoiled. The coils are then unwound and flattened to create flat sheets of aluminum. These sheets are later cut to the desired size and shape, based on the specific design requirements of the architectural panel. Once the aluminum sheets are prepared, various manufacturing techniques can be employed to further process them. Bending, folding, welding, and punching are some of the techniques used to achieve the desired shape and functionality of the panel. The malleability of aluminum enables precise shaping and customization, making it an ideal material for architectural panel production. Furthermore, aluminum coils can undergo coating or treatment to enhance their appearance, durability, and performance. Coatings like paint, powder coating, and anodizing can be applied to the aluminum surface to provide protection against weathering, UV radiation, and corrosion. These coatings also offer aesthetic options, allowing architects and designers to choose from a wide range of colors and finishes for their architectural panels. Architectural panels manufactured using aluminum coils offer numerous advantages. Firstly, due to the lightweight nature of aluminum, these panels are easier to handle and install, resulting in reduced labor costs and time. Additionally, aluminum's corrosion resistance ensures that architectural panels remain durable and visually appealing even in harsh weather conditions. The malleability of aluminum also allows for intricate designs and complex shapes, enabling architects to create visually striking and unique building facades. In conclusion, aluminum coils are an essential component in the production of architectural panels. Their lightweight, corrosion resistance, and malleability properties make them an ideal material for creating durable and aesthetically pleasing panels. Whether it is for high-rise buildings, residential homes, or commercial structures, aluminum coils play a crucial role in the production of architectural panels that enhance the visual appeal and functionality of modern architecture.

- Q: The export of aluminum coil, according to steel coil declaration, will there be any problems?

- If you have already declared itCheck the corresponding HS code, to import countries taxes and fees are the same, whether the customer side mind?.China's tax rebate rate, you also see what kind of high?.In addition to export will have a steel coil sampling, aluminum volume difference is relatively large, so if the declaration, to take note of this, if the sampling try with conversational communication forwarding, otherwise it would be a big problem.

- Q: What is the density of aluminum coils?

- The density of aluminum coils typically ranges from 2.6 to 2.8 grams per cubic centimeter.

- Q: if the resistivity of aluminium is 2.7×10-8 Ωm

- Let ρ be the resistivity of the aluminum cable, A the cross sectional area of the cable and l the cable's length. The resistance R of the aluminum cable is now given by: R = ρ·l / A = 2.7·10^-8·(10·10^3) / (π·r?) = 2.7·10^-8·(10·10^3) / (π·(1·10^-3)?) = 85.9 Ω I guess the tricky part is remembering: R = ρ·l / A but when you realize how intuitive this equation is you don't have to memorize it. The resistance R is proportional to the resistivity ρ, so we must have the following in our equation: R = ρ·k , where k is some value governed by the dimensions of the cable! It is logical that the resistance is also proportional to the wires length l. This is logical when you realize that the longer the wire the more obstacles the electrons will have to pass by! Now we have that: R = ρ·l·c , where c is another value governed now by the cross sectional area (only dimensional property left). If we think of the wire as a highway with cars instead of electrons we realize that there is less resistance (higher speed) when the highway has many lanes and is very broad. From this we realize that the greater the cross sectional area the smaller the resistance. R must therefore be inversely proportional to A. We now have: R = ρ·l / A I hope there are no mistakes here :P

- Q: This question asks for the weight of a single layer of an aluminum coil, which can vary based on its dimensions.

- <p>The weight of a single layer of an aluminum coil depends on its thickness, width, and length. To calculate the weight, you can use the formula: weight = volume 脳 density. The density of aluminum is approximately 2.7 grams per cubic centimeter. If you know the dimensions of the coil, you can calculate its volume and then multiply by the density to find the weight. For example, if the coil has a thickness of 0.1 mm, a width of 1 meter, and a length of 100 meters, the volume would be 0.1 liters or 100 cubic centimeters, and the weight would be approximately 270 kg. However, without specific dimensions, it's impossible to provide an exact weight.</p>

- Q: Yep a slogan...the element Aluminum

- Aluminum: Keeping stoners amazed for over 50 years!

- Q: Are aluminum coils suitable for food processing and packaging?

- Aluminum coils are indeed suitable for food processing and packaging, as aluminum is a highly versatile metal that offers numerous benefits to the food industry. Firstly, it possesses exceptional thermal conductivity, enabling efficient heat transfer during food processing and cooking. This characteristic guarantees even cooking and prevents the formation of hot spots or uneven heating. Moreover, aluminum proves to be an exceedingly corrosion-resistant material, a crucial aspect for food packaging. It effectively shields the food from external elements such as moisture, oxygen, and light, all of which can degrade the quality and freshness of the product. Aluminum coils can be effortlessly molded into various shapes and sizes, making them an ideal choice for packaging a wide range of food products, including cans, pouches, trays, and lids. In addition to these advantages, aluminum is a lightweight material that facilitates convenient transportation and reduces energy consumption during distribution. Its recyclability feature further contributes to minimizing the environmental impact of food packaging. In summary, aluminum coils are exceptionally well-suited for food processing and packaging due to their exceptional thermal conductivity, corrosion resistance, versatility, lightweight nature, and recyclability.

Send your message to us

3003-H16 Aluminum Coil 0.05 X 102 - Aluminum Strips Mill Finished 5xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 g/ft

- Supply Capability:

- 10000 g/ft/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords