18 Gauge Solid Steel Wire in Electro Galvanized

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

18 Gauge Solid Steel Wire in Electro Galvanized

1. Structure of 18 Gauge Solid Steel Wire in Electro Galvanized Description:

18 Gauge Solid Steel Wire in Electro Galvanized is made with choice mild steel, through wire drawing, wire galvanizing and other processes. Galvanized iron wire has the characteristics of thick zinc coating, good corrosion resistance, firm zinc coating, etc.

18 Gauge Solid Steel Wire in Electro Galvanized can be supplied in the form of coil wire, spool wire or further processed into straightened cut wire or U type wire. It is mainly used in construction, express way fencing, binding of flowers and wire mesh weaving.

2. Main Features of 18 Gauge Solid Steel Wire in Electro Galvanized:

• Antirust

• Shiny silvery color

• High strength

• Durable

• Versatile

• Good visual effect

3. 18 Gauge Solid Steel Wire in Electro Galvanized Images

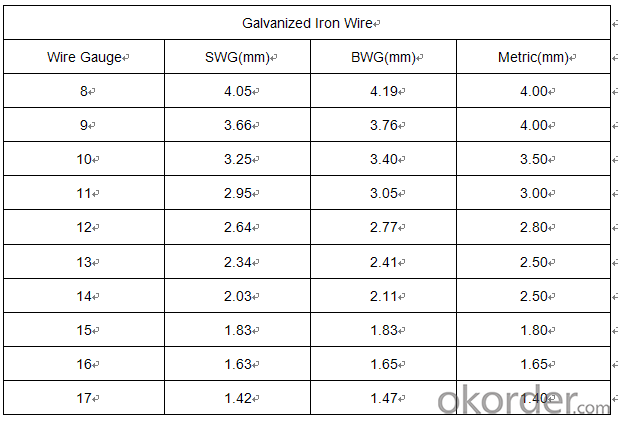

4.18 Gauge Solid Steel Wire in Electro Galvanized Specification

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your products?

One of the most biggest manufacturer & supplier of wires and wire mesh,is a large-scale professional 18 Gauge Solid Steel Wire in Electro Galvanized factory in China. Annually more than 10000 tons wires and wire mesh are exported to markets all over the world.Different kinds of wires and mesh are available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;Our company has good marketing network and abundant operation experience. Galvanized Iron Wire are sold to all parts of the country, at the same time, exported to Southeast Asia,The management theory is based on sincerity, keeping forging ahead. We have accumulated a whole set of marketing experience, having already become a local leader engaged in steel products.

③How long can we receive the product after purchase?

In the purchase of 18 Gauge Solid Steel Wire in Electro Galvanized within three working days, We will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

- Q: Does Frost Wire have virus

- We've had frost wire for a few months now and we've never gotten any viruses from it. Just make sure that you have anti-virus software installed on your computer. To be safe...

- Q: We added an AC to a preexisting sx 80 furnace and we are having a hard time wiring the new thermostat to the furnace, and the condensor to the furnace. Anyone know how to get a wiring diagram?? thanks

- Onewire Armstrong

- Q: How much does it cost to install telephone wires in your household?Does it cost around $200.00 ?

- there's no longer plenty to installation television cable or telephone - you purely pull it by way of the studs to the place the client needs it. you do no longer could desire to hook it up - the cable corporation or the telephone corporation comes and does that. electric powered wiring is particularly extra tense. I think of maximum contractors positioned the cable television and contact in themselves - or they ask the electrician to do it as an afterthought.

- Q: What are the advantages of electric tape over electric wire for a horse?Thank you!!

- I would suggest you keep both electric tape and electric wire away from horses. Electric wire is made of a conductor, usually metal, usually copper or aluminum and covered with a conductor usually plastic such as PVC. It is made to carry electricity to the point of use. Electric tape is a type of insulating tape used by electricians to tape electrical connections. It is usually made of plastic, usually PVC. If you meant house instead of horse, then you would want electrical wire for carrying electricity, properly taped with electrical tape where needed. I have never heard of a conducting tape being used instead of wire for a house. The shape of a tape, with its flat cross section makes it less efficient for carrying electricity and requires much more insulation per conduction capacity.

- Q: In the ceiling is one black, one white and a ground. How do I connect a new ceiling fan to these two wires? The ceiling fan has black wire, white wire, a blue wire and a green wire. We don't have green in the ceiling nor do we have a ground...knob and tube perhaps? So, can we connect this fan or not?Thanks!

- White to white, black and blue to black, green to box.

- Q: Given following setup of three wires in the plane of the page with I1 = 1.3 A (to the right), I2 = 3.4 A (to the right), I3 = 4.5 A(to the left) and each wire is separated by 3 m.I'm completely lost, I need to..1. What is the direction of the magnetic field at wire 3 due to wires 1 and 2?2. What is the direction of the force on wire 3 due to wires 1 and 2?Any help would really be appreciated! Thanks!

- I assume that those wires are sitting parallel 3 m apart from one another. 1. The magnetic field around a wire forms concentric circles around the wire. Wire 1 and Wire 3 are parallel so when you draw a concentric field line around Wire 1 with radius 6 m, you get a magnetic field line passing Wire 3 at a right angle. And a concentric field line around Wire 2 with radius 3 m passes Wire 3 at a right angle. Both magnetic fields have the same direction because the current in both wires flows in the same direction (to the right). Using the right-hand rule, you can find that the magnetic field at wire 3 due to Wire 1 and Wire 2 goes into the page. Ans: Into the page 2. The force on a wire can be calculated in the following manner: I X B * L. Here I is the current on Wire 3, B is the magnetic field due to Wire 1 and Wire 2, L is the length of Wire 3, and X is the cross product operator. So I cross B would give the direction of the force. Now use the right-hand rule, I cross B will give the force direction pointing down. This means the force due to the magnetic field would repel Wire 3 from Wire 1 and Wire 2. Ans: The force on Wire 3 due to Wire 1 and Wire 2 would repel Wire 3 from them.

- Q: i need to make a battery powered light bulb and i have copper wire at home...will it work?

- Copper wire is rather orange in color. If it is insulated it will be surrounded by a coating of plastic for its entire length. If you cut it and then look at its end the copper wire should be in the middle with the insulation around it like a doughnut. Insulation can be of any color and is not always plastic. The copper wire itself can be either solid and made up of a single strand, or stranded and thus composed of numerous much smaller diameter strands. Stranded wire is more flexible and is the type used commonly for lamps, but sold copper wire, although stiffer, will work as well.

- Q: Ok I've been changing the old outlets in the house and all of them were fine until I got to this 1 outlet. The outlet had 1 ground wire, 2 white and 2 black (if that helps). The wires were a little chewed up looking so when I went to wrap the upper white wire to its screw it broke and now the wire won't reach the screw and certain lights in the house won't turn on because of it. I probably should have left it alone because of the condition of the wires but its too late now so how do I go about getting the wire to reach its screw ? Thanks

- The white wire can have a 6 inch* pigtail extension attached to it at the same you spice them together with a wire nut or crimp followed by taping. I'm wondering about the two hot wires though. You didn't say if they too broke apart or were connected separately to the old outlet. If they broke, the same thing can be done for them as you would the white (common) wires. If one half of the old outlet was isolated to respond to a light switch, there's a small break off piece on the outlet that needs to be taken off before you connect them. If you have a meter or a neon tester, it would be good to see which one responds to the switch if you don't know by now. If they were both connected to the outlet without isolation, pigtail them as you did the common and connect one wire only. (The outlet shouldn't be used as the connector between two wires. It wasn't designed for this.) Finally, wrap a couple of turns of tape around the outlet to cover the screws that the wire connects to as it will make further service safer. As most jacks are well marked for polarized hook up, it's hard to see what the writing (if any) is on the back even in good light. Remember the short slot runs hot. Somehow, that's always been the easiest way for me to not forget. *More if you need and there's room in the box. But 6 is standard.

- Q: A vertical straight wire carrying an upward 14.2 A current exerts an attractive force per unit length of 7.80E-4 N/m on a second parallel wire 7.60 cm away. What is the magnitude of the current that flows in the second wire?

- For a current I1 = 14.2 Amperes and radial separation between wires r =0.076 m, the magnetic field at wire 2 is B =0.000037368 Tesla If current I2 = 21 Amperes then the force per meter is F/ΔL =0.000784 Newtons/m hyperphysics.phy-astr.gsu.edu/hba... Goodbye

- Q: What are some of the basic advantages of twisted pair wiring?

- Less interference.

Send your message to us

18 Gauge Solid Steel Wire in Electro Galvanized

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords