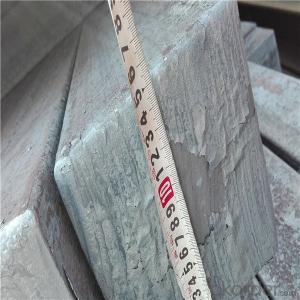

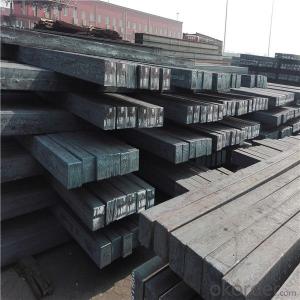

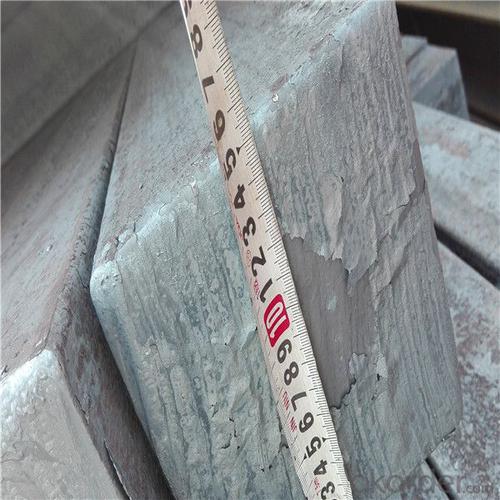

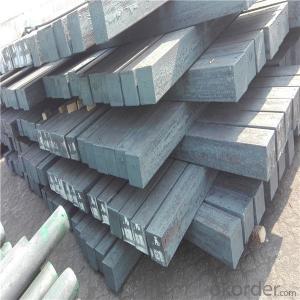

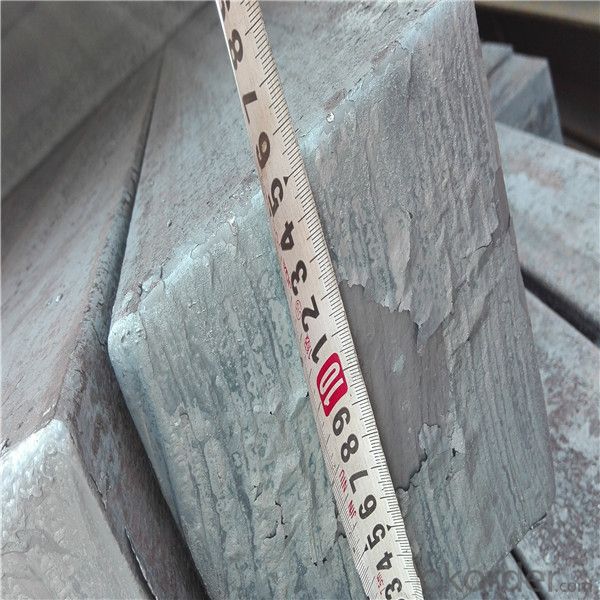

Q275 Square Steel Billets factory sale directly

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 18000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed

into more functional shapes and sizes. While they have already been put in the furnace, they still

require a series of shaping and molding procedures such as hot and cold working, milling and cutting

before they are sold in hardware stores, or used for different applications. The unformed billets,

however, can be used in striking currency such as coins and as reserves, similar to gold bars.

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building

the support foundation pile manufacturing.

Qaulity:own factory, stable quality

Tolerance: Strictly according to the G/B and JIS standard

Delivery time: within 45 days after receiving the L/C or advanced T/T payment.

Price term: FOB/CIF/ CFR according to clients requirements

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: What are the different types of steel billet packaging materials?

- When selecting the suitable packaging material for steel billets, it is crucial to take into account the unique characteristics and benefits of the various options available in the market. The following are some commonly utilized packaging materials for steel billets: 1. Wooden Crates: Renowned for their durability and strength, wooden crates are a favored choice for packaging steel billets. They offer exceptional protection against external impacts and are particularly suitable for long-distance transportation. 2. Steel Strapping: Frequently employed to bundle steel billets together, steel strapping is a robust and secure packaging material. It boasts high tensile strength and resistance to breakage, ensuring that the billets remain intact during handling and transportation. 3. Plastic Wrapping: As a cost-effective and lightweight packaging option, plastic wrapping provides ample protection against moisture and dust, preventing any potential damage to the billets. Moreover, it is easily applicable and removable, rendering it a convenient choice for packaging. 4. Steel Framing: For larger and heavier steel billets, steel framing serves as a heavy-duty packaging material. It offers maximum protection and stability during transportation, effectively minimizing the risk of deformation or damage to the billets. 5. Cardboard Boxes: Smaller steel billets frequently find themselves packaged in cardboard boxes. These boxes are lightweight, easy to handle, and offer sufficient protection against minor impacts and scratches. Additionally, cardboard boxes can be customized in various sizes and shapes to accommodate different billet dimensions. 6. Stretch Film: Stretch film, a flexible packaging material, is commonly employed to wrap steel billets. It provides exceptional protection against moisture, dust, and scratches. Furthermore, stretch film imparts a certain level of stability to the billets, preventing any movement during transportation. When selecting the appropriate packaging material, it is crucial to consider the specific requirements of the steel billets, including size, weight, and transportation conditions.

- Q: What are the main advantages of using steel billets in manufacturing?

- The main advantages of using steel billets in manufacturing include their high strength and durability, versatility in shaping and molding, excellent heat and corrosion resistance, and cost-effectiveness. Steel billets provide a reliable and consistent material for various applications, ensuring structural integrity and longevity in the manufactured products. Additionally, their malleability allows for easy customization and adaptation to different manufacturing processes, making steel billets a preferred choice for many industries.

- Q: What is the lifespan of a steel billet?

- Several factors can influence the lifespan of a steel billet, including the quality of the steel, storage and usage conditions, and the specific application it is used for. Generally, steel billets are designed to have a lengthy lifespan and can withstand years of use without significant deterioration. Steel billets are typically made from high-quality steel that is engineered to possess exceptional strength, durability, and resistance to corrosion. This ensures that the billet can endure the demands of various industrial processes and applications. In terms of storage and usage conditions, it is crucial to store steel billets in a dry and controlled environment to prevent rust and degradation caused by moisture and other contaminants. Proper handling and transportation are also necessary to avoid any physical damage that could compromise their integrity. The lifespan of a steel billet is also influenced by the specific application it is used for. Some billets are utilized in high-stress applications such as construction, automotive manufacturing, or heavy machinery, which subject them to significant wear and tear. In such cases, the lifespan of the billet may be shorter compared to less demanding applications. In conclusion, with appropriate care, maintenance, and adherence to recommended usage guidelines, a steel billet can have a long lifespan ranging from several years to decades. Regular inspections, maintenance, and replacement of worn or damaged billets are vital to ensure optimal performance and safety in various industries.

- Q: What is the role of steel billets in the construction of bridges and tunnels?

- The construction of bridges and tunnels heavily relies on steel billets, which are semi-finished steel products that undergo further processing to create various structural components for the construction industry. For bridges, steel billets are utilized to manufacture steel beams, girders, and columns, forming the core structure of the bridge. These components are essential for providing the required strength and stability to support the bridge's weight and the traffic it carries. Steel billets are chosen due to their high strength-to-weight ratio, making them ideal for constructing long-span and heavy-load bridges. Similarly, in tunnel construction, steel billets are used to create reinforcement bars or rebars. These rebars are embedded within the concrete walls and floors of tunnels, offering additional strength and support to withstand the immense pressure and weight of the surrounding soil or rock. Additionally, steel billets are also employed in fabricating tunnel linings, which protect the tunnel walls from erosion, corrosion, and other forms of deterioration. The utilization of steel billets in bridge and tunnel construction provides several advantages. Firstly, steel is a highly durable and resilient material, capable of withstanding extreme forces, temperature variations, and environmental conditions. This durability ensures the long-lasting nature and structural integrity of bridges and tunnels, reducing maintenance and repair costs over time. Secondly, steel billets can be easily shaped, molded, and welded into various intricate shapes and sizes, allowing for flexibility in design and construction. This versatility enables engineers to create innovative and efficient bridge and tunnel structures, accommodating different architectural and engineering requirements. Lastly, steel billets are renowned for their excellent load-bearing capacity, making them suitable for high-traffic areas such as bridges and tunnels. They can withstand heavy loads and distribute the weight evenly, minimizing the risk of structural failure or collapse. In conclusion, steel billets play a crucial role in the construction of bridges and tunnels by providing the necessary strength, durability, and flexibility. They form the core structure of these constructions, ensuring their stability, longevity, and ability to withstand various environmental and operational challenges.

- Q: What are the different types of steel billet manipulation equipment?

- There are several types of steel billet manipulation equipment, including billet lifting devices, billet transfer cars, billet rotating equipment, and billet storage racks.

- Q: What is the maximum temperature that a steel billet can withstand?

- The maximum temperature a steel billet can withstand is largely dependent on the specific type and grade of steel being used. However, as a general rule, most steels will lose their structural integrity and mechanical properties when exposed to temperatures above 800 degrees Celsius (1472 degrees Fahrenheit). At these elevated temperatures, steel experiences significant thermal expansion, resulting in distortion, warping, and eventual failure. In specialized applications, certain high-temperature alloys or superalloys have the ability to withstand even higher temperatures. These materials are purposefully designed to maintain their strength and durability under extreme heat, often surpassing 1000 degrees Celsius (1832 degrees Fahrenheit) or more. Nevertheless, it is crucial to understand that determining the maximum temperature a steel billet can endure should always involve consulting the technical data sheet specific to the material or seeking advice from experts in the field. Factors such as alloy composition, heat treatment, and intended usage can all contribute to establishing the maximum temperature limit for a steel billet.

- Q: What are the potential applications of steel billets in the food and beverage aftermarket?

- Steel billets have a wide range of potential applications in the food and beverage aftermarket. One potential application is in the production of food processing equipment. Steel billets can be used to manufacture machinery and equipment that is used in food processing plants, such as conveyor belts, food mixers, and cutting tools. The durability and strength of steel make it a suitable material for these applications, as it can withstand the rigors of heavy use and maintain its integrity even in harsh conditions. Another potential application of steel billets in the food and beverage aftermarket is in the construction of storage tanks and containers. Steel is known for its corrosion resistance, making it ideal for storing various food and beverage products. Steel billets can be used to manufacture tanks and containers that can safely store liquids such as water, juices, and alcoholic beverages. These steel tanks can also be insulated to ensure temperature control, which is crucial in preserving the quality of perishable products. Furthermore, steel billets can be used in the production of kitchen equipment and utensils. Steel is a hygienic material that is easy to clean and maintain, making it suitable for use in commercial kitchens and food preparation areas. Steel billets can be shaped into various kitchen utensils such as knives, pans, and cooking pots, which are essential tools in the food and beverage industry. Steel utensils are known for their durability and heat conductivity, which ensures even cooking and efficient food preparation. Overall, the potential applications of steel billets in the food and beverage aftermarket are vast. From food processing equipment to storage tanks and kitchen utensils, steel billets provide a reliable and versatile material for various industries within the food and beverage sector. Its strength, durability, and hygienic properties make it a valuable resource in ensuring the safe and efficient production, storage, and preparation of food and beverages.

- Q: What are the main factors affecting the machinability of steel billets?

- Several key factors influence the machinability of steel billets, which refers to the ease with which they can be cut and shaped by machining processes. These factors encompass the composition of the steel, its microstructure, the presence of impurities or inclusions, and the mechanical properties of the material. The machinability of steel is significantly impacted by its composition. Elements like carbon, manganese, sulfur, and phosphorus play a crucial role in determining the cutting performance. For example, a higher carbon content can increase hardness, thereby making the steel more challenging to machine. Conversely, manganese can enhance machinability by promoting the formation of a favorable microstructure. The microstructure of the steel, influenced by factors such as heat treatment and alloying elements, also affects machinability. Fine-grained steels with a homogeneous microstructure are generally easier to machine compared to coarse-grained ones. Additionally, the inclusion of alloying elements like chromium or molybdenum can enhance machinability by increasing the material's hardness and wear resistance. Machinability can be negatively affected by impurities or inclusions present in the steel, such as non-metallic particles or oxides. These impurities can result in tool wear, surface defects, and inadequate chip formation during machining. Therefore, minimizing the level of impurities in the steel through meticulous production and refining processes is crucial. Moreover, the mechanical properties of the steel, including hardness, strength, and ductility, impact machinability. High-strength steels tend to be more challenging to machine due to their increased hardness, necessitating greater cutting force. Ductility also plays a vital role as it affects the steel's ability to form chips during machining. Striking a balance between hardness and ductility is desirable for optimal machinability. In conclusion, the machinability of steel billets is influenced by various factors encompassing composition, microstructure, impurities, and mechanical properties. It is imperative to comprehend and control these factors to ensure efficient and effective machining processes.

- Q: How are steel billets rolled or forged into other shapes?

- Various shapes can be achieved from steel billets through the process of rolling or forging. Rolling entails passing the heated billet through a series of rollers that exert pressure to reshape the material. This method is commonly employed to fabricate long and flat shapes such as sheets, plates, and bars. Before rolling, the billet is heated to a specific temperature to increase its malleability. It is then introduced into the rolling mill, where a pair of rotating rollers applies pressure to reduce its thickness and elongate it. The rollers can have either smooth or grooved surfaces, depending on the desired shape of the end product. The billet undergoes multiple passes through the rollers, gradually diminishing its thickness and increasing its length. This process can be repeated with different sets of rollers to achieve precise dimensions and cross-sectional shapes. Finally, the product is cooled and cut to the desired length. On the other hand, forging involves applying compressive forces to the heated billet in order to shape it into various forms. There are two primary types of forging processes: open-die forging and closed-die forging. In open-die forging, the heated billet is inserted between two flat dies, and pressure is exerted by a hammer or press to deform the material. The billet is repeatedly struck or pressed until it takes on the desired shape. This method is commonly used for the production of large and intricate shapes, such as crankshafts, connecting rods, and turbine discs. Closed-die forging, also referred to as impression-die forging, entails the use of two or more dies with cavities that mirror the desired shape of the final product. The heated billet is positioned between the dies, and pressure is applied to compel the material into the cavities, completely filling them. This process is often employed for the fabrication of smaller and more intricate shapes, such as automotive parts, hand tools, and fittings. Both rolling and forging processes necessitate the heating of the billet to a specific temperature in order to enhance its ductility and facilitate shaping. The choice between rolling and forging depends on factors such as the desired shape, size, and mechanical properties of the final product.

- Q: What industries rely heavily on steel billets?

- Steel billets are an essential raw material for numerous industries, with construction being one of them. The construction industry relies on steel billets to fabricate structural components like beams, columns, and reinforcement bars, which are crucial for constructing buildings, bridges, and infrastructure projects. The strength and durability provided by steel billets are necessary for these construction applications. Another industry heavily dependent on steel billets is the automotive industry. They are used to manufacture different automotive parts, including engine components, chassis, and suspension systems. Steel billets are ideal for producing parts that can endure rigorous conditions and ensure vehicle safety due to their high strength and versatility. The oil and gas industry is also heavily reliant on steel billets for the production of pipelines, drill pipes, and other equipment used in exploration, extraction, and transportation processes. Steel billets are preferred in this industry for their corrosion resistance, high pressure resistance, and ability to withstand extreme temperatures. Furthermore, the machinery and equipment manufacturing industry extensively utilizes steel billets as the primary material for producing a wide range of machinery, including industrial machinery, agricultural equipment, and heavy-duty machinery. Steel billets provide the necessary strength, toughness, and machinability required for these applications. Moreover, the aerospace industry heavily depends on steel billets for manufacturing various aircraft components like landing gear, structural frames, and engine parts. Steel billets are chosen for their high strength-to-weight ratio, heat resistance, and ability to withstand the demanding conditions of aerospace applications. In conclusion, steel billets are indispensable in various industries such as construction, automotive, oil and gas, machinery and equipment manufacturing, and aerospace. Their unique properties ensure the production of strong, durable, and reliable products, making them vital for these industries.

Send your message to us

Q275 Square Steel Billets factory sale directly

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 18000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords