125 Aluminum Sheets in Spfd Mo for Sale - Aluminum Boat for Fishing with Different Sizes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Quick Details

| Place of Origin: | Shandong, China (Mainland) | Brand Name: | Allheart | Model Number: | HT625 |

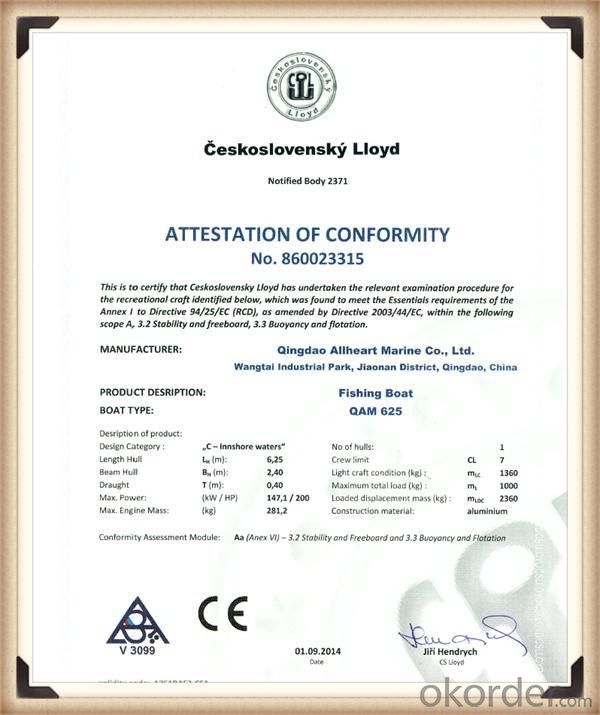

| Hull Material: | Aluminum | Certification: | CE | Capacity (Person): | 10 |

| Length: | 6.25-8m | color: | optional |

Packaging & Delivery

| Packaging Details: | 1)Fishing Boat package according to export standard 2)Fishing Boat package based on seaworthy standard 3)Special package as customer's request |

| Delivery Detail: | within 45 days after 30% deposit |

6.25m cuddy cabin | ||

SPECIFICATIONS | STANDARD FEATURES | STANDARD FEATURES |

Length of Hull: 6.25m | 3 Years Warranty | Seat: Ocean Pro & box storage |

Beam: 2.3m | Rear Ladder | Cleat on Front Deck |

Depth: 1.45m | Windscreen | Floor: Front Casting Platform |

Sides:4mm | Rod Holders (4) | Rail: Transom & Cabin Grabrail |

Bottomsides: 5.00mm | Bollard/Boweye | Rail:Long Side Rails & Low Bowrails |

Topsides: 4.00mm | Anchorwell | Transducer Brackets x 2 |

Transom Material: 5.00mm | Cabin and hard Top | Seat: Cabin Cushions |

Transom Shaft Length: L/L | Double chimes | Cleat On Transom Corners |

Weight (boat only):1155kg | Carpet wooden floor | Twin Battery Box & Switch |

Rec. HP: 150hp | TMC bilge pump | Underfloor Fuel Tank 200 Litres |

Max. HP: 200hp | Under the floor flotation | Seat: Folding Rear Lounge |

Main Motor Weight: 315kg | Cutting Board (Alloy) | fishing tank 60L |

umber of People (Level): N/A | Self Drain Floor Treadplate | Trim Tabs |

Number of People: 8 | Side Pockets (2) | Bait tank 30L |

FAQ

Q: What models do you have available?

A: We currently offer the following layouts for the 498 Series:

Angler 498A - Side Console Boat

Bay Fisher 498F - Center Console Boat

Bay Rover 498R - Runabout Boat

Sports Cuddy 498S - Cuddy Cabin Boat

We also offer 4.6m versions of these boats, they are identical except for the twin rear swimming platforms.

Q: I want to see the boats in person, where can I find them?

A: We have showrooms in Japan (Osaka), Australia (Sydney, Brisbane and Melbourne), and other countries. Please see our website at www.MorningstarBoats.com for a complete list. We are also happy to organize factory tours for you if you would like to come to Taiwan for a visit.

Q: Could you pre-install outboard engines for me?

A: Yes, we can provide Mercury and Evinrude outboards, from 40HP to 115HP.

Q: Could you provide boat trailers?

A: Yes, we have boat trailers specially designed for our aluminum boat hulls.

Q: Do I need drainage for my boat?

A: Aluminium floor without drainage is like most small boats, when you moor it in the harbour and it keeps raining, water will start to accumulate. Once the water level from under the deck is high enough, the automatic bilge pump will be triggered and starts pumping out water.

Our Services

We provide the following products:

14ft, 15ft, 16ft and 17ft aluminum luxury boats (4.6m ~ 4.98m). This is our most popular range.

10ft, 11ft, 12ft, and 13ft small aluminum fishing boats (car toppers and open boats, 3.2m ~ 4.1m) Guranteed low prices!

5.5m Rigid-Hulled Inflatable Boats (RIBs) with aluminum hulls

We provide many customization options.

Contact us NOW for the best boat money can buy!

- Q: Inquire whether aluminum sheets are generally more costly compared to other sheet metal materials.

- <p>Aluminum sheets are not necessarily more expensive than other types of sheet metal. The cost can vary based on factors such as the current market price of the metal, the thickness and grade of the sheet, and the specific alloy used. Generally, aluminum is less expensive than metals like stainless steel or copper, but it can be more expensive than common metals like steel or iron. Prices fluctuate, so it's best to check current market prices for the most accurate comparison.</p>

- Q: What is the fire rating of 101 aluminum sheets?

- The fire rating of 101 aluminum sheets is typically dependent on the particular alloy and thickness of the sheets. Due to its low melting point of 660 degrees Celsius (1220 degrees Fahrenheit), aluminum has the potential to deform or melt when exposed to intense heat. Nevertheless, it is important to highlight that aluminum is not flammable and does not aid in the propagation of fire. Fire resistance can be improved by applying fire-resistant coatings or by incorporating it with other fire-resistant substances. In conclusion, it is crucial to seek advice from manufacturers or industry professionals to ascertain the fire rating of specific 101 aluminum sheets.

- Q: Can aluminum sheets be easily shaped or bent?

- Indeed, aluminum sheets possess a remarkable capability to be effortlessly molded or flexed. Renowned for its exceptional malleability and ductility, aluminum exhibits a remarkable propensity to be readily fashioned into diverse contours and curves. The manipulation of this versatile metal can be accomplished through an assortment of techniques, encompassing rolling, pressing, and even manual utilization of tools. Given its pliability, aluminum emerges as the preferred choice within industries such as automotive, aerospace, and construction, wherein the fabrication of intricate shapes and bends is a common necessity. Moreover, the lightweight nature and inherent resistance to corrosion further enhance aluminum's suitability for shaping and bending endeavors.

- Q: What is the typical tensile strength of aluminum sheets?

- The specific grade or alloy being used can cause variations in the typical tensile strength of aluminum sheets. Typically, the tensile strength of aluminum sheets falls between 20,000 and 50,000 pounds per square inch (psi). It is worth mentioning that this is a wide range and the exact tensile strength can be affected by factors such as the sheet's thickness, the manufacturing process, and any additional treatments or coatings applied to the aluminum. Hence, it is advisable to refer to the manufacturer's or supplier's specifications for accurate information regarding the tensile strength of a particular aluminum sheet.

- Q: The user is asking if aluminum sheets can be used as a substitute for metal siding in construction.

- <p>Yes, aluminum sheets can be used to replace metal siding. They are lightweight, durable, and resistant to corrosion, making them a popular choice for siding. Aluminum sheets can be painted or finished to match various architectural styles and are low maintenance. However, it's important to ensure that the aluminum sheets are of the appropriate gauge and quality for the application, and that they are installed correctly to ensure longevity and performance.</p>

- Q: This question asks for a list of various fasteners that are commonly used in the installation process of aluminum sheets.

- <p>There are several types of fasteners used for installing aluminum sheets, including: 1. Self-tapping screws, which create their own threads in the material. 2. Rivets, which join two pieces of material by compressing them together. 3. Pop rivets, a type of rivet that can be installed using a handheld tool. 4. Structural adhesives, which bond the sheets together without visible fasteners. 5. Welding, although not a fastener, it's a method used to join aluminum sheets permanently. 6. Mechanical fasteners like bolts and nuts, which are tightened to secure the sheets. 7. Clips and clamps, used for temporary or decorative installations. Each type has its own advantages and is chosen based on the specific requirements of the installation, such as load-bearing needs, aesthetic considerations, and the environment in which the aluminum sheets will be used.</p>

- Q: Is it possible to use aluminum sheets as a material for exterior wall covering?

- <p>Yes, aluminum sheets can be used for exterior cladding. They are known for their durability, resistance to corrosion, and low maintenance requirements. Aluminum is lightweight, which makes it easier to install compared to heavier materials. It also has good thermal properties, helping to insulate buildings. Additionally, aluminum can be coated with various finishes, allowing for a wide range of aesthetic options. However, it's important to ensure proper installation and sealing to prevent water infiltration and to maintain the cladding's performance over time.</p>

- Q: Hello,Does it matter what kind of wheel I use as a cut off wheel on an angle grinder when cutting aluminum?Thanks!

- you can use the standard metal cut-of wheels as a last resort...but the low melting point of aluminium and granularity of lower grades of alu mean that you disc will clog up, so it doesn't cut efficiently, and you will get a messy cut with a lot of slag around the cut which then needs a lot of filing to tidy up. Special cut off wheels for cutting aluminium are available. You can cut alu with a circular saw as its nor harder than say oak... but again because of the low melting point you need a saw blade designed for cutting aluminum. Finally cutting aluminium with a circular saw requires that you use the right amount of force, to hard and you'll get a rought cut or stall the motor, too soft and you cover the blade in melted alu.

- Q: What is the difference between the alloy 1060H24 aluminum plate and the alloy 1100H24 aluminum plate?

- At present, most of the circulation in the market is 1050 and 1060 series. 1000 series aluminium plate to determine the minimum aluminum content in this series according to the amount of the last two Arabia figures, such as the 1050 series of the last two Arabia number 50, according to the international brand naming principles, content must reach 99.5% to the top for qualified products. China's aluminum alloy technology standard (gB/T3880-2006) is also clearly defined, 1050 aluminum content of 99.5%., the same reason, 1060 series aluminum plate aluminum content must reach more than 99.6%

- Q: Are aluminum sheets suitable for decorative lighting fixtures?

- Yes, aluminum sheets are highly suitable for decorative lighting fixtures. Aluminum is a lightweight and versatile material that is easy to work with and manipulate into various shapes and designs. It offers excellent corrosion resistance, making it suitable for both indoor and outdoor lighting fixtures. Additionally, aluminum can be easily coated or painted to achieve different finishes, allowing for endless design possibilities. Its reflective properties also contribute to enhancing the overall lighting effect, making it an ideal choice for decorative lighting fixtures.

Send your message to us

125 Aluminum Sheets in Spfd Mo for Sale - Aluminum Boat for Fishing with Different Sizes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords