Brown Anodized Aluminum Sheets - 1100 3003 3105 Color Coated Aluminum Sheet and Colored Aluminum Coil for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum alloy wallboard standard:

PCM is the technique of the printing pre-coating (roll coating) no color difference.

The specification of the wall board: | Max Width 1700mm |

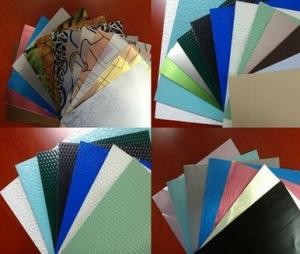

Aluminum alloy sheet: | Base on AA1100, AA3003, AA3004, AA3105, AA5052, AA5754, 1.0-4.0mm thick aluminum alloy panels , according to the Chinese National Standard. |

Painting method: | Adopt the most advanced PCM printing , 2 coating and 2 backing, no color difference, extreme flatness technique method. |

Frontispiece painting: | Adopt KYNAR 500 (more than 70% fluorocarbon resin) |

Frontispiece guarantee: | Coating guarantee for 20 years. |

Film of Face protecting: | Adopt PVC film, standard thickness is 80 μ |

Color requirements: | Color according to the color board or color number of the client’s order. |

As a credible manufacturer in this field, we guarantee a best quality & short delivery with a long timed experience and technical know-how and wish your company to have a chance to meet a world best-raw material partner!

Our product's details are as following and we need to know some info from you, in order to give you the best price.

1. Your wanted Alloy, Thickness and Size of aluminum sheet

2. Your main use of our aluminum sheet

3. Approximate needed quantity

4. RAL color number ,thickness of the painting film both surface

Packaging Details:

1). Each coil to be securely tied with two bands.

2). the contact points of these bands on the coil edge to be protect with edge protectors.

3). Coil then to be properly wrapped with plastic film ,woven belt, resistant paper.

4). Wooden or iron pallet can be used or as your requirements.

- Q: Can aluminum sheet be used for heat exchangers?

- Yes, aluminum sheet can be used for heat exchangers. Aluminum has excellent thermal conductivity and is lightweight, making it a suitable material for transferring heat efficiently in heat exchangers. Its corrosion resistance and durability also make it a popular choice in various heat exchange applications.

- Q: What are the different alloys available for aluminum sheets?

- There are several alloys available for aluminum sheets, including 1100, 3003, 5052, and 6061. Each alloy has different properties and characteristics, making them suitable for various applications.

- Q: Can aluminum sheets be textured or patterned?

- Yes, aluminum sheets can be textured or patterned. There are various techniques that can be used to create textures or patterns on aluminum sheets, such as embossing, engraving, or etching. These methods involve altering the surface of the aluminum sheet to create a desired texture or pattern. Additionally, aluminum sheets can also be coated or painted with different finishes or colors to achieve a specific textured or patterned appearance. Overall, with the right techniques and processes, aluminum sheets can be transformed and customized to have a wide range of textures and patterns.

- Q: how to find 0.6mm waste strake of aluminum sheet?

- Heating wire is mainly used for electrical heating, has large power consumption. But aluminum sheet’s cooling fin mainly uses steam or hot water to conduct Thermal dissipation, it needs hot water or steam boiler. Comparatively, Heating wire conducts Thermal dissipation quicker, but cools quicker after power outage. Aluminum sheet is in the opposite condition.

- Q: What are the different fabrication methods used for aluminum sheets?

- Some of the different fabrication methods used for aluminum sheets include rolling, extrusion, casting, and stamping.

- Q: How to carry out drawing process in aluminium plate

- The process of repeated scraping is an essential step in the production and processing, and we can not forget. The second is in the process of the film, to make the drawing processing after more shiny, look more beautiful, the film is the key technology in the field of production and processing. Should be careful, careful, can not be careless, such a careful and responsible work attitude, for drawing aluminum plate each place to do the details of the treatment, so that the filaments will be dense and bright.

- Q: What are the different surface patterns or textures available for aluminum sheets?

- Aluminum sheets come in various surface patterns and textures, each designed for specific purposes and offering unique aesthetic appeal. Some commonly used surface patterns for aluminum sheets are as follows: 1. Smooth: These sheets have a flat and polished surface without any visible patterns or textures. They are ideal for applications that require a clean and sleek appearance, such as architectural elements or interior design. 2. Diamond Plate: These sheets have a raised diamond pattern on the surface, providing excellent traction and slip resistance. They are commonly used for flooring, stairs, ramps, and industrial applications where grip and durability are essential. 3. Brushed: These sheets have a consistent linear pattern created by brushing the surface with fine abrasive pads. This finish gives a satin-like appearance, making it popular for decorative purposes like signs, furniture, appliances, and automotive trim. 4. Stucco: These sheets have a raised pattern that resembles a stucco wall finish. The texture is achieved by embossing the sheet with a stucco roller, creating a rough and durable surface. Stucco patterned sheets are commonly used for exterior cladding, roofing, and decorative applications. 5. Hammered: These sheets have a unique texture that resembles the surface of hammered metal. The finish is achieved by imprinting the sheet with a pattern of small indentations using a hammer or similar tool. Hammered sheets are often used for decorative purposes, such as backsplashes, countertops, and art installations. 6. Perforated: These sheets have a pattern of small holes punched into the surface, allowing for airflow, light transmission, and sound absorption. They are commonly used for architectural elements, screens, filters, and ventilation systems. These examples represent just a fraction of the surface patterns and textures available for aluminum sheets. Each texture serves a specific purpose and offers distinct visual appeal, enabling a wide range of applications in various industries.

- Q: I have seen some stainless steel rifles that you can basically dunk in water, require no cleaning, etc and perform time after time. If SS is so good why are most weapons made of aluminum parts which is then anodized coated black? If you dunk these weapons in water will they rust? Thanks

- Stainless steel will rust.. It does have small amounts of carbon in it It just takes longer... Than carbon steel to stain Aluminum works for low stress parts ... AR lowers, hand gun frames If the part is stressed or needs wear resistance it generally is made of tool or ordinance grade steel-carbon or stainless

- Q: How do you bend aluminum sheets?

- To bend aluminum sheets, you can use a variety of methods such as using a bending machine, a brake press, or even hand tools like a mallet and a block of wood. The process typically involves clamping the sheet securely, applying gradual pressure to the desired bending point, and manipulating the metal until the desired angle is achieved. It is important to take into consideration the thickness of the sheet and use appropriate techniques to avoid damaging or cracking the aluminum.

- Q: There are about 200 holes on the aluminum plate to be machined. There are 100 M12 thread holes, and the rest are 15MM through holes. The tolerance is +0.02. Seeking detailed processing technology, is the first hole or first processing plane, how to control the amount of deformation of the plate, if the milling process can not guarantee flatness, on the grinder, then the 2 surfaces to stay 2MM margin? Are there any 15MM through holes that can be used to maintain tolerances, or do they need to be boring?. Great God advice, the best detail. Aluminum so much done before, no experience, if it does it scrapped.

- Such a large plate flatness 0.1 you don't need it, basically do not, we used 1000*700 processing board, directly buy imported aluminum plate, ensure the factory within 0.05, leveling back after processing to find professional leveling company OK, I was also called grinding waste, the deformation of grinding plate will be great, so there is no need to consider

Send your message to us

Brown Anodized Aluminum Sheets - 1100 3003 3105 Color Coated Aluminum Sheet and Colored Aluminum Coil for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords