Aluminum Coil Sheet 3003 for Curtain Wall Decoration - Color Coating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coating Aluminium Coil 3003 for Curtain Wall Decoration

Name | 3003 Aluminum Coil |

Brand | CNBM |

Alloy | 1100H-18, 3003-H24,3003-H26,3005-H26,8011,3004,3105,5005,etc. |

Thickness | 0.1~1.5mm |

Width | <2000mm< span=""> |

MOQ | 1 MT |

Coating finish | Brushed, drawing, embossed, printing |

Color | As to code RAL |

Surface | Embossed,Mill Finish,Coated,Brushed |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | PVDF27 ~35micron |

Polyester18~27micron(EN ISO-2360:1995) | |

Coating hardness | 2H |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

MEK resistance | 100 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 1MT - 2MT |

2. Application of Color Coating Aluminium Coil 3003 for Curtain Wall Decoration

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coating Aluminium Coil 3003 for Curtain Wall Decoration

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

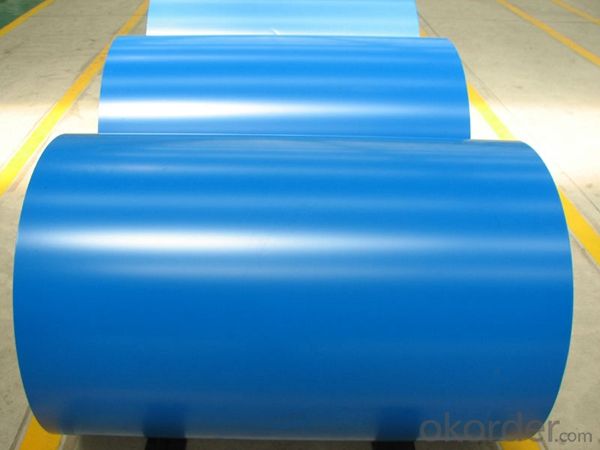

5. Image of Color Coating Aluminium Coil 3003 for Curtain Wall Decoration

6. Package and shipping of Color Coating Aluminium Coil 3003 for Curtain Wall Decoration

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What causes tower after cutting aluminum coil

- Insulation aluminum coil will appear when the cooling bending phenomenon, reason is generally under the conditions of air cooling, the heat transfer coefficient of the aluminum coil insulation parts in contact with the air were flat, but because the wall thickness or different shapes, different parts of the heat dissipation rate is not balanced, resulting in thick wall or hollow tube heat faster than the thin Department of slow, resulting in insulating aluminum roll cooling occurs to the hollow part.

- Q: Is there a system or initiative in place for recycling aluminum coils?

- <p>Yes, there are recycling programs for aluminum coils. Many recycling centers accept aluminum coils, and some manufacturers have their own recycling programs. Aluminum is highly recyclable, and recycling it saves energy and resources. To recycle aluminum coils, you can contact local recycling facilities or check with the manufacturer for specific programs. Some regions also have e-waste recycling programs that may accept aluminum coils from electronic devices. It's important to clean and prepare the coils for recycling to maximize their value and recyclability.</p>

- Q: What is the maximum width of aluminum coils?

- The maximum width of aluminum coils is subject to variation based on several factors, including the manufacturing process, the specific grade and type of aluminum, and the capabilities of the equipment employed. Nevertheless, in broad terms, the maximum width of aluminum coils can span from a few inches to multiple feet. Industrial coil lines ordinarily possess the capacity to handle widths up to 72 inches, whereas specialized machinery might be capable of accommodating even wider coils. To ascertain the precise maximum width applicable to a specific application, it is crucial to consult with the manufacturer or supplier.

- Q: I can't figure out what the metabolic role of aluminum is. Been searching for a while and can't seem to find anything concrete.If you can, please include sources. Thanks!

- I don't think it has any role.

- Q: This question asks for an explanation of the various materials used for coating aluminum coils.

- <p>Aluminum coil coating materials can be categorized into several types, including: 1. Organic coatings, such as polyester, acrylic, and polyvinylidene fluoride (PVDF), which offer good weather resistance and color stability. 2. Inorganic coatings, like fluoropolymers, which provide exceptional chemical resistance and high-temperature stability. 3. Metal coatings, such as zinc or other metals, used for enhanced corrosion resistance. 4. Ceramic coatings, which are known for their high durability and resistance to heat and chemicals. 5. Laminates, which combine multiple materials for specific performance characteristics. These coatings are chosen based on the intended application of the aluminum coil, such as in construction, automotive, or packaging industries.</p>

- Q: This question asks for an explanation of the various types of coatings that can be applied to aluminum coils.

- <p>Aluminum coils can be coated with several types of materials to enhance their properties for various applications. The main types include: 1. Anodized Coatings: These provide a protective oxide layer on the aluminum surface, enhancing corrosion resistance. 2. PVDF (Polyvinylidene Fluoride) Coatings: Known for their durability and resistance to UV rays, chemicals, and weathering. 3. Polyester Coatings: These are used for general-purpose applications due to their balance of properties like formability and chemical resistance. 4. PVF2 (Polyvinylidene Fluoride) Coatings: Similar to PVDF but with a thinner film, offering good weather resistance. 5. Acrylic Coatings: Known for their flexibility and adhesion, suitable for both interior and exterior applications. 6. Silane Coatings: Provide a thin, protective layer that enhances paint adhesion and corrosion resistance. Each type serves different purposes, and the choice depends on the specific requirements of the application.</p>

- Q: Can aluminum coils be used in the production of lighting fixtures?

- Yes, aluminum coils can be used in the production of lighting fixtures. Aluminum is a lightweight and durable material that is commonly used in various industrial applications, including lighting fixtures. It offers excellent heat dissipation properties, making it suitable for housing and cooling components in lighting fixtures. Additionally, aluminum coils can be easily shaped and formed to create different designs and sizes of fixtures, making them a versatile choice for manufacturers.

- Q: Is it possible to use a metal detector to locate an aluminum coil?

- <p>Yes, you can use a metal detector to detect aluminum coils. Metal detectors are designed to detect various types of metal, including aluminum. While they are often used for detecting ferrous metals like iron, they can also pick up non-ferrous metals such as aluminum. The effectiveness of detecting aluminum may vary depending on the type of metal detector and its sensitivity settings. Ground conditions and the size and composition of the aluminum coil can also affect detection. It's important to adjust the metal detector to the appropriate settings for detecting non-ferrous metals to increase the chances of successful detection.</p>

- Q: How are aluminum coils processed for surface preparation?

- To ensure proper adhesion of coatings, improve corrosion resistance, and enhance overall appearance, various surface preparation processes are carried out on aluminum coils. These processes typically include cleaning, degreasing, and etching. To begin with, the coils undergo a cleaning process to eliminate any dirt, dust, or contaminants. This can be achieved through either mechanical or chemical methods. Mechanical cleaning involves the use of brushes, scrubbers, or high-pressure water spray to physically remove impurities from the surface. On the other hand, chemical cleaning involves the application of mild alkaline or acidic cleaning agents that dissolve and eliminate contaminants. Following the cleaning process, the coils are degreased to eliminate any remaining oils or greases. This can be done using solvents or an alkaline degreasing process. Solvent-based degreasers are applied to the coil surface, allowing them to dissolve and remove any oil or grease residues. Alternatively, alkaline degreasing involves immersing the coils in an alkaline solution that reacts with the grease, resulting in the formation of soap that can be easily rinsed off. Once the coils have been cleaned and degreased, they may undergo an etching process to enhance surface roughness and promote better adhesion of subsequent coatings. Etching can be carried out using chemical or electrolytic methods. Chemical etching involves immersing the coils in an acidic solution that removes a thin layer of aluminum oxide from the surface, creating a roughened surface. On the other hand, electrolytic etching utilizes an electrical current to remove the oxide layer. After the surface preparation steps, the aluminum coils are typically rinsed with water to remove any residual cleaning or etching chemicals. Subsequently, the coils are dried to ensure a clean and dry surface, ready for the application of coatings or further processing. In conclusion, the surface preparation of aluminum coils involves a combination of cleaning, degreasing, and etching processes to achieve a clean, smooth, and properly prepared surface for subsequent treatments.

- Q: Are aluminum coils suitable for beverage can manufacturing?

- Aluminum coils are indeed appropriate for the production of beverage cans. Aluminum is the favored material for this purpose because of its numerous beneficial characteristics. To begin with, aluminum is lightweight, enabling easy transportation and handling. This is especially crucial in the beverage industry, where a substantial number of cans are manufactured and distributed. Furthermore, aluminum possesses high malleability, allowing it to be shaped into the desired form without compromising its structural integrity. This quality makes it perfect for the manufacturing of cans, as it can be effortlessly molded into the cylindrical shape required and withstand the pressure exerted by carbonated beverages. Moreover, aluminum is non-toxic, ensuring that it does not contaminate the beverages stored within the cans. It also acts as a protective barrier against light, oxygen, and moisture, effectively preserving the flavor and quality of the beverages. Additionally, aluminum is recyclable, thus making it an environmentally friendly option for can production. The recycling process for aluminum consumes significantly less energy than the production of new aluminum, rendering it a sustainable material choice. In summary, the appropriateness of aluminum coils for beverage can manufacturing is evident due to their lightweight nature, malleability, non-toxicity, preservation properties, and recyclability.

Send your message to us

Aluminum Coil Sheet 3003 for Curtain Wall Decoration - Color Coating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords