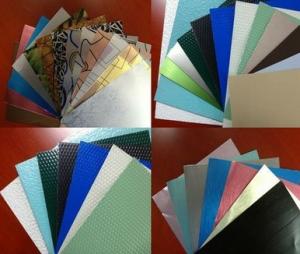

Anodized Aluminum Sheets Home Depot 1100 3003 3105 Color Coated Aluminum Sheet/Coil for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. specification of aluminum sheet / coil

Division | Thickness(m/m) | Width(m/m) | Note |

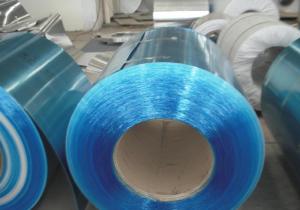

Coil | 0.2~5.0mm | Max1850mm | Inside diameter 505mm, Outside diameter Max 1,300mm |

Sheet | 0.2~200mm | 160-1850mm | Length Max6000mm |

Circle | 0.5~4.8mm | 160~1000mm | diameter |

Length of aluminum sheet : popular length 1500mm-6000mm ( special length can be produced as your requirement )

Alloy Grade : 1050,1060,1100,3003,3004,3005,3105,5005,5052,5083,5754,6061,6063,etc.

Temper : H12,H44,H16,H18,H22,H24,H26,H32,H34,etc.

2. Application & Feature of aluminum sheet / coil

Division | Alloy | Application | Feature |

1000 SERIES | 1050 1060 1070 1200 | Utensil, decoration, Reflecting plate, printing plate, heatproof plate, cookware | -Easy to process and weld, resistant to rust, high conductibility of electricity and heat, low strength

|

3000 SERIES | 3003 3005 3105 | Utensil(F/P, inside of rice cooker), aluminum can, material for interior and exterior of building,chemical equipment Cellular Phone | 20% higher strength than the 1100 series, easily welded and brazed, good antirust ability Non-heat treatable |

5000 SERIES | 5083 5052 5754 5A05 | Ship board heatproof apparatus, material for interior and exterior of building, Parts of Electronic tools Automobile Components: | -Excellent corrosion resistance andweld ability together with Easy to process and weld and superior hardness &heatproof Can be anodized for increased corrosion resistance |

6000 SERIES | 6061 6063 | IT equipment & facility, Mould material, motor material, automatic line, machine & plant etc. | -Easy to process , good corrosion resistance, high toughness and processed without distortion after heat-treatable, superior surface treatment |

8000 SERIES | 8011 | Kitchen utensils, Bottle cap | -8000 series is durable to process with special alloy. |

Packaging & Delivery

| Packaging Details: | standard export package or as per customer reques |

| Delivery Detail: | 30 days |

- Q: What is made when Aluminium and Hydrochloric Acid reacts? It makes a dense white smoke with a metallic odour in the gas. Could it be dissolved amounts of Aluminium Chloride or small amounts of unreacted Aluminium in the gas? Or could be that the Chlorine (in equilibrium with HCl and HClO) made chlorates and perchlorates of aluminium that give off odours?Don't tell me the gas isn't supposed to have an odour. I know what diatomic Hydrogen smells like. Nothing. That's the way it should be. But unfortunately, that's not the way it is.

- i might call the plumber immediately. curiously there's a hollow interior the piping someplace, and the sulfuric acid would desire to have eaten by in spite of advance into clogging that hollow. I doubt that it will supply up leaking via itself, to no longer point out that acid is in all risk leaking into your kitchen in the present day.

- Q: Are aluminum sheets suitable for outdoor uses like fences or signs?

- <p>Yes, aluminum sheets are commonly used for outdoor applications such as fences and signage. Aluminum is lightweight, durable, and resistant to corrosion, making it ideal for outdoor conditions. It can withstand various weather elements without rusting. Additionally, aluminum can be easily formed into different shapes and sizes, and it's available in a wide range of colors and finishes, which makes it versatile for both functional and aesthetic purposes in outdoor settings.</p>

- Q: Are aluminum sheets suitable for beverage cans?

- Yes, aluminum sheets are suitable for beverage cans. Aluminum is a widely used material in the beverage industry due to its unique properties. It is lightweight, corrosion-resistant, and provides an excellent barrier against light, oxygen, and moisture, which helps to preserve the quality and freshness of the beverage. Additionally, aluminum is easily formable, allowing for the production of various can shapes and sizes. It is also recyclable, making it an environmentally friendly choice. Overall, aluminum sheets are an ideal material for beverage cans, meeting both functional and sustainability requirements.

- Q: What types of aluminum sheets are recommended for outdoor applications?

- <p>Yes, there are specific types of aluminum sheets suitable for exterior use. These include aluminum sheets with a protective coating, such as anodized aluminum, which offers enhanced resistance to corrosion and weathering. Additionally, aluminum sheets with a Kynar 500庐 PVDF coating are highly resistant to UV rays, making them ideal for exterior applications. Marine-grade aluminum is also recommended for exterior use due to its superior corrosion resistance, especially in coastal areas. These types of aluminum sheets are designed to withstand harsh outdoor conditions and maintain their integrity over time.</p>

- Q: Explain how aluminum sheets impact the soundproofing capabilities of a building.

- <p>Aluminum sheets can have a significant impact on the sound insulation of a building. They are often used as a cladding material due to their durability and low maintenance requirements. However, aluminum is a good conductor of sound, which means it can transmit sound waves efficiently. This can reduce the sound insulation of a building, especially if the aluminum sheets are not combined with other soundproofing materials. To improve sound insulation, aluminum sheets can be combined with insulation materials, such as polyurethane foam, to create a barrier that reduces sound transmission. Additionally, using thicker aluminum sheets or adding a layer of sound-absorbing material can help enhance the soundproofing capabilities of a building.</p>

- Q: What is the typical hardness of aluminum sheets?

- The typical hardness of aluminum sheets can vary depending on the specific alloy and temper. However, aluminum sheets generally have a hardness ranging from 40 to 70 on the Brinell hardness scale (HB). This level of hardness allows aluminum sheets to be easily formed, machined, and fabricated, making them suitable for a wide range of applications in industries such as aerospace, automotive, construction, and manufacturing. It is important to note that the hardness of aluminum sheets can be further enhanced through heat treatment processes, such as annealing or hardening, to meet specific requirements and improve their mechanical properties.

- Q: If something is wrong, what kind of glue can be used for bonding the stainless steel sheet and aluminum sheet? The area may be very big. What are some common or good glue to buy?

- Is the whole surface covered with glue or covered with four sides?What are you asking for?This kind of structure can use more glue,Acrylic structural adhesive, epoxy structural adhesive, silicone structural adhesiveNeed to understand glue, we can communicate,

- Q: i have a aluminum bicycle the first time i painted it i painted over the original paint(didnt know any better). The second time i sanded it down with some paint left on it. Now this time im sanding it but im using 60grit it looks good to me is 60 grit to much.

- You screwed up. 60 grit should NEVER come in contact with aluminum... those scratches will never come out. NEVER have an aluminum frame sandblasted. You'll need to have it soda blasted or walnut shell blasted. You should be using 220 grit ALUMINUM OXIDE paper- it is white in color. My bet is that you are using garnet- the brown stuff, or maybe coated paper. You MUST use aluminum oxide. I have answered the question to paint a bike a hundred times. Just click on Discover and type in the words paint a bike without quotes. Theres your answer.

- Q: Do you use aluminum alloy boards or aluminum plates for outdoor billboards?

- Aluminum alloy low density, but relatively high strength, close to or higher quality steel, plastic good, can be processed into various profiles, with excellent conductivity, thermal conductivity and corrosion resistance, widely used in industry, the use of only steelIn general, outdoor billboards are made of aluminium alloy sheets

- Q: Are the aluminum sheets recyclable?

- Yes, aluminum sheets are recyclable.

Send your message to us

Anodized Aluminum Sheets Home Depot 1100 3003 3105 Color Coated Aluminum Sheet/Coil for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords