Bulk Aluminum Sheets - Mill Finished Aluminum Coil 3003 Alloy for Color Coating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finished Aluminum Coil 3003 Alloy for Color Coating

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC |

TEMPER | H14,H18,H24,H26,H32 |

THICKNESS | 0.2MM-20MM |

WIDTH | 10mm-1500mm |

COIL WGT | 2Mt - 3Mt |

Coil ID | 20" |

SURFACE | Mill finished etc |

STANDARD | GB/T 3880-2006 |

2. Application of Mill Finished Aluminum Coil 3003 Alloy for Color Coating

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finished Aluminum Coil 3003 Alloy for Color Coating

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

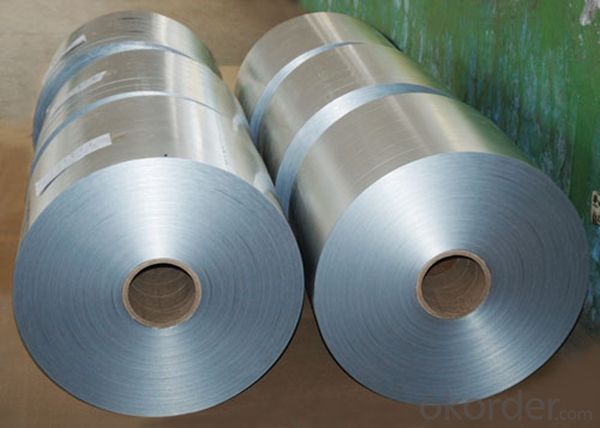

5. Image of Mill Finished Aluminum Coil 3003 Alloy for Color Coating

6. Package and shipping of Mill Finished Aluminum Coil 3003 Alloy for Color Coating

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can 101 aluminum sheets be used in the production of consumer electronics?

- Indeed, consumer electronics production can indeed benefit from the usage of 101 aluminum sheets. Aluminum, being a versatile and lightweight material, finds wide application in the manufacturing of various electronic devices like smartphones, laptops, tablets, and other consumer electronic products. It boasts exceptional properties such as excellent thermal conductivity, corrosion resistance, and electrical conductivity, thus rendering it highly suitable for electronics. It is worth noting that the particular grade of aluminum, such as 101, may possess distinct characteristics that cater to diverse applications. However, in the absence of further information regarding the specific requirements of the consumer electronics being fabricated, it becomes challenging to ascertain whether 101 aluminum sheets are the optimal choice.

- Q: What kind of paint would you like to paint on the aluminum plate?

- Nitro paint, polyester paint can be mainly your base, you should use atomic ash treatment before you can use, otherwise it will peel off

- Q: What are the rules or laws concerning the application of flame-retardant coatings on aluminum sheets?

- <p>Yes, there are regulations regarding the use of flame-retardant coatings on aluminum sheets. These regulations vary by country and application, but they generally aim to ensure safety and compliance with fire safety standards. In the United States, for example, the National Fire Protection Association (NFPA) provides guidelines, and building codes like the International Building Code (IBC) may specify requirements for flame retardancy. The European Union has its own set of standards, such as EN 13501, which classifies the reaction to fire performance of construction products. Compliance with these regulations is crucial to ensure that the aluminum sheets and their coatings meet the necessary safety standards and to avoid legal penalties.</p>

- Q: What are the different types of patterns available for aluminum sheets?

- There are several different types of patterns available for aluminum sheets, including diamond, tread, stucco, and perforated. Each pattern offers unique aesthetic and functional properties, catering to various applications and design preferences.

- Q: I have a lot of old aluminum cake pans, coffee pots, pots and pans and various old nuts and bolts made of aluminum. Would it be worth it to scrap them? They really aren't usable for cooking anymore. They are clean.

- Aluminum is around 80 cents - 1$ per lb depending on grade. For current pricing you can try www.scrapmetalpricesandauctions.c...

- Q: Are 101 aluminum sheets suitable for chemical transfer piping?

- No, 101 aluminum sheets are not suitable for chemical transfer piping. Aluminum is generally not recommended for handling certain chemicals due to its reactivity and potential for corrosion. It is more commonly used in industries that require lightweight materials and good thermal conductivity, such as aerospace or construction. For chemical transfer piping, it is advisable to use materials that are resistant to corrosion and can withstand the specific chemicals being transported, such as stainless steel, PVC, or high-density polyethylene (HDPE).

- Q: on an hot day, which will stay cooler longer...aluminum, or copper? why?thanks!

- Copper is a better conductor of both heat and electricity so it will get hotter faster at least until it oxidizes and turns green

- Q: Can aluminum sheet be used for aerospace applications?

- Yes, aluminum sheet can be used for aerospace applications. Aluminum is a lightweight metal with good strength-to-weight ratio and excellent corrosion resistance, making it an ideal choice for aerospace components such as aircraft skins, wings, and structural parts.

- Q: What is the typical torsional strength of aluminum sheets?

- The typical torsional strength of aluminum sheets can vary depending on various factors such as the alloy composition, thickness, and manufacturing process. However, in general, aluminum sheets have a good torsional strength compared to other materials. Aluminum alloys commonly used in sheet form, such as 6061-T6 and 5052-H32, have torsional strengths ranging from approximately 22,000 to 40,000 pounds per square inch (psi). These values represent the maximum amount of torque that can be applied to the aluminum sheet before it permanently deforms or fractures. It is important to note that torsional strength is just one aspect of the overall mechanical properties of aluminum sheets. Other factors like tensile strength, yield strength, and elongation also play significant roles in determining the suitability of aluminum sheets for specific applications. Therefore, when selecting aluminum sheets for a particular torsional application, it is essential to consider the specific requirements and consult with material suppliers or engineers to ensure the chosen aluminum sheet meets the desired torsional strength requirements.

- Q: Can aluminum sheets be used in electrical applications?

- Yes, aluminum sheets can be used in electrical applications. Aluminum is a good conductor of electricity, and it is commonly used in various electrical components and applications. Aluminum sheets are often used as conductive materials in power transmission lines, bus bars, and electrical enclosures. They are also utilized in the manufacturing of capacitors, transformers, and heat sinks due to their excellent thermal conductivity properties. Additionally, aluminum sheets are lightweight and corrosion-resistant, making them suitable for electrical applications where weight and durability are important factors.

Send your message to us

Bulk Aluminum Sheets - Mill Finished Aluminum Coil 3003 Alloy for Color Coating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords