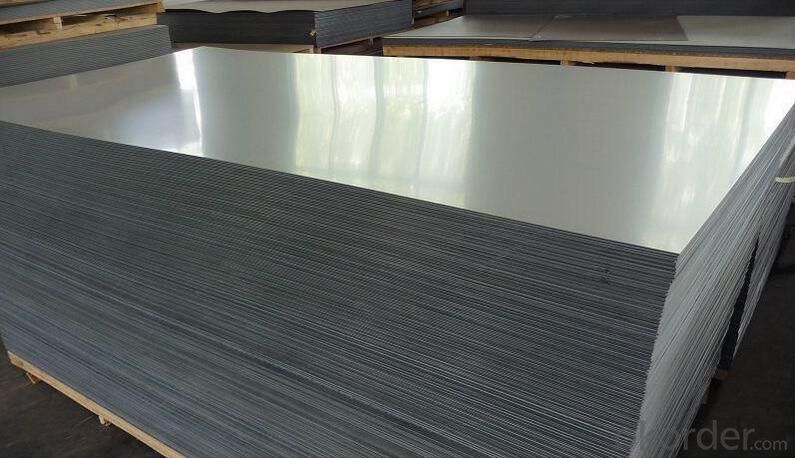

Matte Finish 1070 H18 Aluminum Mirror Sheets in Silver for Reflective Chimney

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1070 H18 aluminum mirror sheets in silver for Reflective chimney

ALLOY : AA1***(AA1050,AA1060,AA1070,AA1100etc)

AA3***(AA3003,AA3004,AA3005,AA3105etc)

AA5***(AA5052 etc)

TEMPER:H14,H18,H24,H26,H32

THICKNESS:0.2mm-20mm

WIDTH:10mm-1500mm

EMBOSSED PATTERNS : Diamond, stucoo,bars etc

STANDARD: GB/T3880-2006

Special specification is available on customer's requirement

Product Description

Goods name | Aluminum plate |

alloy | Yes |

Plance of origin | China |

Quality | Prime quality |

Certificate | ISO9001 |

Grade | 3000 Series |

Thickness | 0.3-150mm |

Type | Plate |

Width | 300-1950mm |

Model number | 3003,3004,3005,3014,3105 |

Surface | Mill finish |

Temper | O-H112 |

Ensure | we can supply customers' with different specifications of the highest quality and lowest price. Sincerely welcome to contact us for the future details if any item interest you ,and we will make every effort to assure that your requirements will be satisfied,and we hope to establish long-term business relations with you on the basis of the equality and mutual benefit. |

- Q: How does the surface finish of aluminum sheet affect its cleaning requirements?

- The surface finish of aluminum sheet plays a significant role in determining its cleaning requirements. The different surface finishes available for aluminum sheet, such as mill finish, brushed finish, or anodized finish, can impact how dirt, grime, and other contaminants adhere to the surface. In general, smooth and polished surface finishes like brushed or anodized are more resistant to dirt and stains, making them easier to clean. These finishes have a lower surface roughness, which creates fewer areas for dirt particles to adhere to. As a result, they can be cleaned more effectively with gentle cleaning solutions or even just water and a soft cloth. On the other hand, aluminum sheets with a mill finish or a rougher surface may require more intensive cleaning methods. The higher surface roughness of these finishes can create more areas for dirt and grime to get trapped, making it harder to remove them with simple cleaning techniques. In such cases, more aggressive cleaning solutions or abrasive cleaning tools might be necessary to remove stubborn stains or dirt particles. It is important to note that the specific cleaning requirements for aluminum sheet also depend on the type and intensity of the contaminants present. For example, if the aluminum sheet is exposed to harsh chemicals or corrosive substances, special cleaning methods may need to be employed to ensure complete removal and avoid any potential damage. In summary, the surface finish of aluminum sheet directly affects its cleaning requirements. Smoother and polished finishes are generally easier to clean due to their lower surface roughness, while rougher finishes may require more intensive cleaning methods. Understanding the surface finish of aluminum sheet is crucial in determining the most appropriate cleaning techniques to maintain its appearance and functionality.

- Q: What is made when Aluminium and Hydrochloric Acid reacts? It makes a dense white smoke with a metallic odour in the gas. Could it be dissolved amounts of Aluminium Chloride or small amounts of unreacted Aluminium in the gas? Or could be that the Chlorine (in equilibrium with HCl and HClO) made chlorates and perchlorates of aluminium that give off odours?Don't tell me the gas isn't supposed to have an odour. I know what diatomic Hydrogen smells like. Nothing. That's the way it should be. But unfortunately, that's not the way it is.

- When aluminum reacts with hydrochloric acid heat is produced as well as aluminum chloride. This heat is warming up the HCl, which you should remember is a gas dissolved in water, a little of which evolves from the water. You're smelling HCl gas. There shouldn't be any dense white smoke, unless you've got an open container of ammonia nearby. In that case the smoke is particulate ammonium chloride, produced by the reaction in the air of HCl and NH3.

- Q: Can aluminum sheets be used for decorative or architectural purposes?

- Aluminum sheets have multiple uses in decoration and architecture. This versatile material can be easily shaped and molded into various forms, making it perfect for a wide range of architectural projects. It is commonly utilized in exterior cladding, roofing, window frames, and facades, lending a sleek and contemporary appearance to buildings. Moreover, aluminum sheets are also employed for decorative purposes like wall panels, art installations, signage, and furniture. Architects and designers often choose aluminum due to its lightweight and durable properties, enabling them to create visually appealing and functional structures. Additionally, aluminum's resistance to corrosion makes it suitable for both indoor and outdoor applications.

- Q: Can aluminum sheet withstand heavy loads?

- Yes, aluminum sheet can withstand heavy loads. Aluminum is known for its high strength-to-weight ratio, making it an excellent choice for applications that require durability and load-bearing capabilities. Aluminum sheets are commonly used in industries such as aerospace, automotive, construction, and marine, where heavy loads are involved. Additionally, aluminum's inherent corrosion resistance further enhances its ability to withstand heavy loads over extended periods. However, it is important to consider the specific grade and thickness of the aluminum sheet, as different alloys and thicknesses have varying load capacities.

- Q: Are aluminum sheets suitable for signage applications?

- Indeed, signage applications can benefit from the use of aluminum sheets. Due to its lightweight nature and durability, aluminum proves to be an ideal material for outdoor signs that must endure diverse weather conditions. Its resistance to rust and corrosion guarantees the sign's longevity. Moreover, aluminum sheets can be effortlessly customized and shaped into various sizes, enabling the creation of versatile and imaginative signage options. Furthermore, aluminum serves as an exceptional material for digital printing, producing top-notch graphics and images. All in all, aluminum sheets present remarkable durability, versatility, and aesthetic allure, cementing their status as a favored choice for signage applications.

- Q: What is aluminium plate L2-Y2?

- China plastic deformation of pure aluminum grades are 1080, 1080A, 1070, 107000A (L1), 1370, 1060, 1050 (L2), 1050A (L3), 1A50 (LB2), 1350, 1145, 1035 (L4), 1A30 (L4-1), 1100 (L5-1), 1200 (L-5), 1235. Iron and silicon are their major impurities and are increasing by the number of brands.2, Y2: indicates that the material is in a semi hard state

- Q: If I were to make an aluminum mold and cover it with a release agent, could I cast aluminum into it? Or would the two parts fuse together? I'm trying to find an alternative to sand casting.Thank you!

- Aluminum okorder /... I use investment lost wax casting.

- Q: What are the safety standards for aluminum sheets utilized in construction?

- <p>Yes, there are safety standards for aluminum sheets used in construction. These standards ensure the material's quality, strength, and suitability for various applications. They include specifications for thickness, alloy type, and surface treatment. International standards such as ASTM B209 (for aluminum sheet and plate) and EN 485 (for aluminum and aluminum alloy sheets) govern the production and use of aluminum sheets in construction. Compliance with these standards is crucial for safety, durability, and to meet regulatory requirements in different regions.</p>

- Q: What type of aluminum plate does the traffic sign use? 1100?

- The aluminum alloy sheet of grade 3003 should be adopted in the road with higher technical level,The large sign board or the sign board of the coastal windy area should adopt the aluminum alloy sheet of grade 3004 or 3104.

- Q: What are the benefits of using aluminum sheets?

- There are several benefits of using aluminum sheets in various applications. Firstly, aluminum sheets are lightweight, making them easy to handle and transport. This characteristic is particularly advantageous in industries such as aerospace, automotive, and construction, where weight reduction is crucial for fuel efficiency and overall performance. Secondly, aluminum sheets offer excellent corrosion resistance. Unlike other metals, aluminum naturally forms a protective oxide layer when exposed to air, preventing further corrosion and enhancing its durability. This makes aluminum sheets highly suitable for outdoor applications or in environments with high humidity or corrosive substances. Another benefit of using aluminum sheets is their high strength-to-weight ratio. Aluminum is known for its exceptional strength, allowing it to withstand heavy loads or extreme conditions without compromising its structural integrity. This makes it an ideal choice for constructing lightweight but sturdy structures, such as building facades, vehicles, or industrial equipment. Additionally, aluminum sheets are highly malleable and ductile, meaning they can be easily formed into various shapes and sizes. This flexibility allows for intricate designs and customization, making aluminum sheets highly versatile and adaptable to different manufacturing processes or project requirements. Furthermore, aluminum is a sustainable and environmentally friendly material. It is 100% recyclable, meaning it can be reused repeatedly without losing its properties or quality. Recycling aluminum requires significantly less energy compared to the production of primary aluminum, resulting in reduced carbon emissions and a reduced environmental impact. Lastly, aluminum sheets have excellent thermal and electrical conductivity properties. This makes them suitable for applications that require efficient heat transfer or electrical conductivity, such as heat exchangers, solar panels, or electrical wires. Overall, the benefits of using aluminum sheets include their lightweight nature, corrosion resistance, high strength-to-weight ratio, malleability, sustainability, and excellent thermal and electrical conductivity. These advantages make aluminum sheets a popular choice in various industries, contributing to improved performance, cost-effectiveness, and environmental sustainability.

Send your message to us

Matte Finish 1070 H18 Aluminum Mirror Sheets in Silver for Reflective Chimney

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords