1070 Mirror Surface Aluminum Sheets for Curtain Wall - Rhode Island

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1070 Mirror Surface Aluminum Sheets for Curtain Wall

l Product Introduction

Aluminium has a lot of salient properties that the other metals do not have. It is very strong, yet it is not very heavy. Like other metals, it conducts electricity and heat to a moderate degree. Most industries require aluminium sheets for various purposes. Aluminium can be easily beaten into sheets because of its high malleability. It has the preoperty of light weight, medium strength, easy-forming and anti-corrosion.

l Product Description

Product | 1070 mirror aluminum sheet for curtain wall |

Alloy | 1050 1060 1070 1100 3003 3005 5005 5083 8011 |

Temper | H14 H16 H18 H24 H26 |

Thickness | 0.3mm~0.5mm |

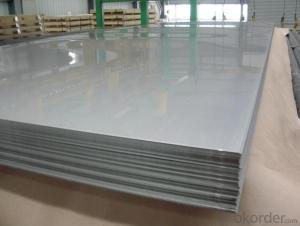

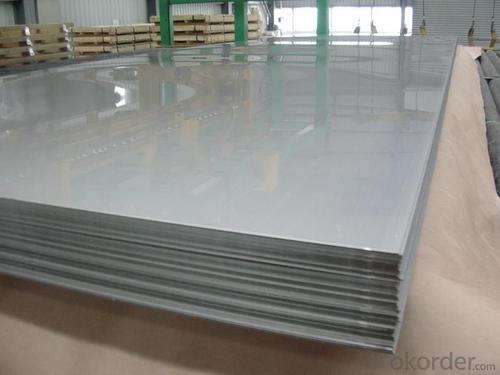

Feature | the surface is as bright and smooth like the mirror |

Application |

|

l Packaging & Delivery

Packaging detail: Seaworthy Export Standard Wooden Pallet and with damp proof film as first layer, Kraft paper as second layer, Cardboard card as third layer Criss-cross steel strip to fix outside

Delivery detail: About 25 days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

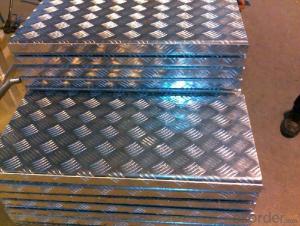

l Products Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: Is it possible to utilize aluminum sheets as a material for constructing roofs?

- <p>Yes, aluminum sheets can be used for roofing materials. They are known for their durability, lightweight, and resistance to corrosion. Aluminum is also energy-efficient, reflecting heat and reducing cooling costs. It's recyclable and has a long lifespan, making it an environmentally friendly choice. However, it may not be as impact-resistant as some other materials and can be more expensive upfront.</p>

- Q: What is the typical modulus of elasticity of aluminum sheets?

- The typical modulus of elasticity of aluminum sheets varies depending on the alloy and temper. However, a commonly used value is around 70 GPa (gigapascals) or 10 million psi (pounds per square inch). This value represents the stiffness or rigidity of the material, indicating its ability to withstand deformation under applied stress. It is important to note that different grades and conditions of aluminum may have slightly different modulus of elasticity values, so it is recommended to consult the specific material specifications for accurate information.

- Q: Can aluminum sheets be anodized for aesthetic purposes?

- Aluminum sheets have the ability to undergo anodization for the purpose of aesthetics. Anodization is an electrochemical procedure that forms a protective oxide layer on the surface of the aluminum. This layer has the potential to be colored in a variety of shades, thus offering a wide range of aesthetic possibilities. Anodized aluminum sheets are highly sought after in the field of architecture, particularly for constructing facades, due to their enduring and visually pleasing appearance. Furthermore, the anodized layer bolsters the aluminum's resistance to corrosion and wear, making it suitable for both indoor and outdoor applications. Moreover, anodized aluminum sheets can be subjected to additional processes like etching or laser engraving, enabling the creation of intricate designs and patterns.

- Q: This question asks about the various applications of aluminum sheets within the construction industry.

- <p>Aluminum sheets are widely used in construction for their durability, lightweight, and resistance to corrosion. They are commonly used for roofing and cladding due to their ability to withstand harsh weather conditions. Aluminum sheets are also used in the manufacturing of window frames and doors because of their strength and thermal insulation properties. Additionally, they are utilized in the construction of scaffolding and temporary structures due to their ease of assembly and disassembly. In interior design, aluminum sheets can be used for decorative purposes, such as wall panels and ceilings. Their recyclability also makes them an environmentally friendly choice for construction projects.</p>

- Q: Can aluminum sheets be used for automotive body panels?

- Yes, aluminum sheets can be used for automotive body panels. In fact, aluminum is increasingly being used in the automotive industry for its lightweight properties and high strength-to-weight ratio. Using aluminum sheets for body panels helps reduce the overall weight of the vehicle, which in turn improves fuel efficiency and performance. Additionally, aluminum is highly resistant to corrosion, making it a durable choice for automotive applications. The use of aluminum sheets for automotive body panels has become especially popular in the production of electric vehicles, as their lightweight construction helps maximize the range of the vehicle.

- Q: Can aluminum sheets be stamped or pressed?

- Yes, aluminum sheets can be stamped or pressed.

- Q: What are the physical properties of aluminum sheets?

- Aluminum sheets possess several physical properties, including being lightweight, corrosion-resistant, and having a high strength-to-weight ratio. They are also ductile, meaning they can be easily shaped or formed without breaking. Additionally, aluminum sheets have excellent thermal and electrical conductivity, making them suitable for various applications in industries such as construction, aerospace, and automotive.

- Q: What precautions should be taken while handling aluminum sheets to ensure safety?

- <p>When working with aluminum sheets, it's important to take certain safety measures. Always wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a dust mask to protect against sharp edges and metal dust. Ensure good ventilation to avoid inhaling aluminum dust, which can be harmful. Use proper tools designed for metal work to prevent accidents. Keep the work area clean and free from clutter to minimize trip hazards. Be cautious of electrical hazards if using power tools, and ensure all tools are in good working order. Finally, be aware of the fire hazard potential of aluminum, especially when cutting or welding, and have fire extinguishers readily available.</p>

- Q: Are aluminum sheets conductive?

- Yes, aluminum sheets are conductive. Aluminum is a metal and has a high electrical conductivity. This means that electricity can easily flow through aluminum sheets, allowing them to be used in various applications where conductivity is required, such as in electrical wiring, power transmission lines, and electronic devices.

- Q: does aluminum sheet need to conduct ROHS detection?it's metel material, how much detections should it conduct for ROHS detection?

- It's ok for detecting four items of ROHS heavy metal for ROHS detection of metal material.

Send your message to us

1070 Mirror Surface Aluminum Sheets for Curtain Wall - Rhode Island

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords