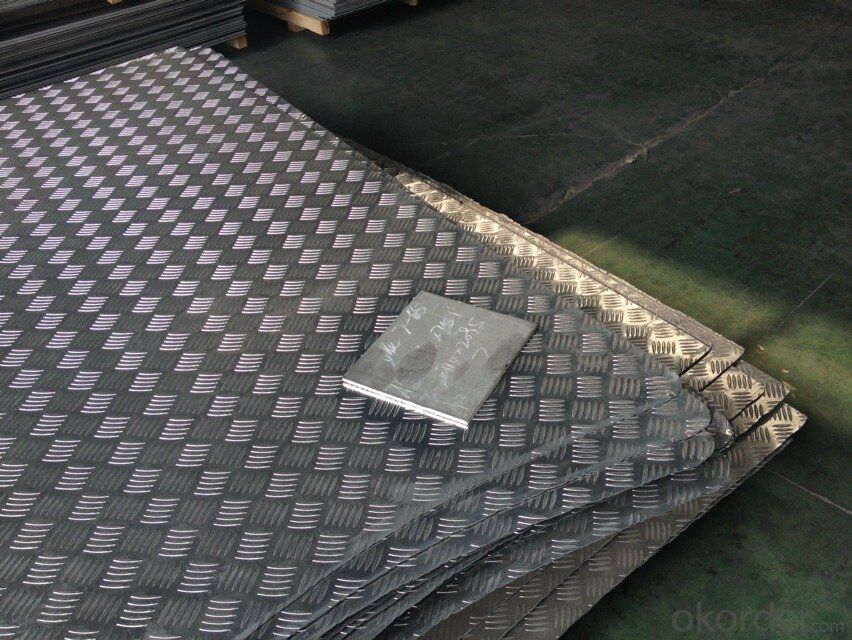

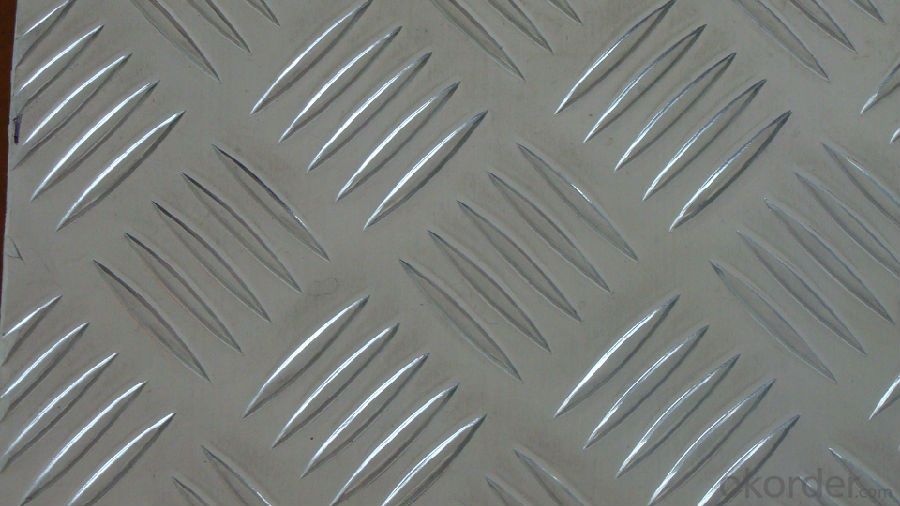

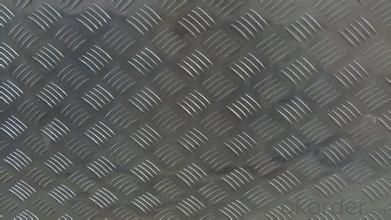

Aluminum Sheets Utah - 1050 1060 1100 3003 5052 5 Bar Aluminum Tread Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

aluminum chequered plate are widely usd for bus, cars and shipping vessel as the floor....

Aluminum tread plate is also called anti-slide aluminum sheet which is widely used in manufacturing vehicles, ships, washing machines, refrigerator shell, etc.

Specification:

Denomination | Final application | Temper | Thickness | Width | Inner diameter | Outside |

diameter | ||||||

Semi-rigid container foil | Food container applied in aviation | 3003/8011--H22,H24,O | 0.02-0.09 | 300-600 | 76/152 | 100-600 |

Household foils | Soft packing in household | 8011--O | 0.01-0.02 | 200-700 | 76 | 200-800 |

Pharmaceutical foil | Packing for Blister foil | 8011--H18 | 0.020-0.025 | 400-1100 | 76/152 | 760 |

Cable foil | Wraping for cable | 1100/8011,O | 0.15-0.05 | 500-800 | 76 | 760 |

Aluminum fin stock | Hear exchanger and condensator for A/C | 8011--H24,O | 0.1-0.13 | 400-1000 | 152 | 760 |

Cigarette foil | Packing for cigarette | 1235--O | 0.0065-0.007 | 460,520 | 76 | 400 |

Foil for hot seal | Hot seal cover for acidophilus milk and other beverage | 1235/8011--O | 0.02-0.038 | 400-600 | 76 | 760 |

Thick foil for deep processing | Seal for beer bottle | 1145/8011,O | 0.0115 | 300-600 | 76/152 | 400/760 |

Shield for video cable | 0.01-0.012 | 500 | 76 | 400 | ||

Aluminum adhesive tape | 0.2-0.06 | 300-600 | 76/152 | 400/760 | ||

Thin foil for deep-processing | Foil with thickness less than ten micron applied in surface of packing materials | 8011/1235--O | 0.0065-0.007 | 460-1000 | 76 | 400 |

Foil for automobile radiator | Water tank radiator in automobile | 8011/1050--H18 | 0.08-0.10 | 140-600 | 76 | 760 |

Packing:

One roll in an individual box or printed PP bag

Certain quantities in a standard carton

Depends on customer’s request

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

- Q: This question asks for a comparison between aluminum sheets and other types of sheet metal regarding their strength and durability.

- <p>Aluminum sheets are known for their high strength-to-weight ratio, making them lighter than many other sheet metals such as steel. They offer excellent corrosion resistance, which contributes to their durability. However, in terms of sheer strength, aluminum is not as strong as steel or titanium. Steel is stronger but also heavier, and while titanium is very strong and durable, it is also more expensive and less commonly used in construction and manufacturing. Aluminum's malleability allows it to be easily shaped and formed, and it is also non-magnetic and has good thermal conductivity. Overall, aluminum is a popular choice for applications requiring a balance between strength, weight, and resistance to corrosion.</p>

- Q: How do you prevent oxidation of exposed edges of aluminum sheets?

- To prevent oxidation of exposed edges of aluminum sheets, there are a few effective methods that can be employed: 1. Apply a protective coating: One of the most common ways to prevent oxidation is by applying a protective coating on the exposed edges of aluminum sheets. This can be done using various types of coatings, such as paint, lacquer, or a specialized protective coating designed specifically for aluminum. These coatings act as a barrier, preventing the aluminum from coming into contact with oxygen and moisture, which are the primary causes of oxidation. 2. Use anodizing: Anodizing is a process in which a protective oxide layer is created on the surface of aluminum. By subjecting the aluminum sheets to an electrolytic process, a controlled and thick layer of oxide is formed, which acts as a barrier against oxidation. Anodizing also provides additional benefits such as improved corrosion resistance and enhanced aesthetics. 3. Implement proper storage and handling: Proper storage and handling practices can also help prevent oxidation of exposed edges. Aluminum sheets should be stored in a dry and well-ventilated area, away from moisture and humidity. It is important to avoid storing aluminum sheets directly on the ground or other surfaces that may cause them to come into contact with moisture. Additionally, gloves should be worn during handling to minimize the transfer of oils from the skin, which can accelerate oxidation. 4. Regular cleaning and maintenance: Regular cleaning and maintenance of aluminum sheets can help prevent oxidation. This involves removing any dirt, grime, or other contaminants that may accumulate on the surface, as they can contribute to the oxidation process. Cleaning can be done using mild soaps or detergents, and a soft cloth or sponge. After cleaning, it is important to thoroughly dry the aluminum sheets to remove any remaining moisture. By implementing these preventive measures, the oxidation of exposed edges of aluminum sheets can be effectively minimized, ensuring their longevity and maintaining their aesthetic appeal.

- Q: aluminum is used to make planes, cast iron is used to make heavy mashines. what is the comparisonof teh densities of aluminum and cast iron?

- The density of aluminum is MUCH lower than cast iron (thus, aluminum is LIGHTER). Because it is lighter, it would be much more ideal for applications like plane building, which is why aluminum is used over cast iron in airplanes. As well, aluminum has a protective coating called aluminum oxide which protects it from corroding in water. [Answer: see above]

- Q: I need to install hand rails around a hot tub and wonder if aluminum would work well.

- Aluminum is not a good choice, even if it's anodized, painted, or powder coated. Pool water is corrosive mostly due to the chloride from chlorination. Steel is slightly less prone to corrosion. Plastic or fiberglass is the best choice.

- Q: Can aluminum sheet be used for aerospace structural components?

- Yes, aluminum sheet can be used for aerospace structural components. Aluminum is commonly used in the aerospace industry due to its desirable properties such as low density, high strength-to-weight ratio, and excellent corrosion resistance, making it suitable for various structural applications in aircraft and spacecraft.

- Q: Are aluminum sheets suitable for signage and advertising?

- Yes, aluminum sheets are highly suitable for signage and advertising purposes. Aluminum is a durable and lightweight material, making it ideal for creating signs that can withstand outdoor weather conditions and transportation. Its resistance to rust and corrosion ensures that the signs will maintain their appearance and functionality over time. Aluminum sheets can be easily cut and shaped into various sizes and designs, making them versatile for different advertising needs. Additionally, aluminum's smooth surface allows for high-quality printing and graphics, providing excellent visibility and readability for signage. Overall, with its durability, versatility, and aesthetic appeal, aluminum sheets are a practical and effective choice for signage and advertising.

- Q: Can aluminum sheet be used for architectural applications?

- Aluminum sheet is indeed suitable for architectural purposes, thanks to its impressive strength, durability, and resistance to corrosion. It is widely utilized in the construction field for various architectural applications such as cladding, roofing, and facades. Architects and designers can select aluminum sheets in different thicknesses to meet their specific aesthetic and functional requirements. These sheets can be easily shaped, bent, and formed to create distinctive architectural elements like panels, screens, louvers, and decorative features. Moreover, aluminum sheets can be coated or finished to enhance their appearance and protect them from environmental factors. Techniques such as anodizing, powder coating, or painting can be employed to improve the material's resilience against weathering, UV radiation, and pollution. Due to its lightweight nature, aluminum is favored for architectural applications as it reduces the overall weight of the structure and facilitates convenient installation. Additionally, aluminum is an environmentally friendly option for architectural projects as it can be recycled infinitely, thus promoting sustainability. To summarize, aluminum sheets are a highly viable and popular choice for architectural purposes because of their strength, versatility, durability, and aesthetic appeal.

- Q: Are aluminum sheets suitable for solar reflectors?

- Yes, aluminum sheets are suitable for solar reflectors as they have excellent reflective properties, high thermal conductivity, and are lightweight, making them an ideal material for maximizing solar reflectance and minimizing heat absorption.

- Q: What are the aluminum plates for?

- Defense (cover containing polyethylene moistureproof layer of kraft paper embossing aluminum alloy), special mould. The tensile aluminum alloy aluminum coated aluminum. Special stamping. Electronic gasket aluminum, alloy aluminum alloy electric radiator. Special aluminum curtain wall coating. (fluorocarbon, polyester) aluminum coil, aluminum coil, special signs aluminum plate, color coated aluminum sheet, aluminum ceiling coating, aluminum plate, aluminum plate pattern, embossing aluminum / aluminum (pointer type, orange peel pattern, diamond, five ribs, aluminum strip). Aluminum wire and cable, transformer Using aluminum strip, aluminum foil, pressure type aluminum corrugated corrugated aluminum plate. Color coating, special aluminum plate, aluminum plate cable tray, material: 1100.1200.1050A.1060.1070.1080.1145.2A11.3003.3A21.3004.3005.3104.3105.LF21.5A02.5A05.5005.5754.5052.5083.5082.5A03.6061.6063.6082.8011. material; H111.H112.H18.H26.H16.H22.H32.H34.H36.H14.H24.H12.T4.T5.T6.O.F state can meet the requirements of customers

- Q: Are 101 aluminum sheets suitable for aerospace tooling?

- No, 101 aluminum sheets are not suitable for aerospace tooling. Aerospace tooling requires materials with high strength, stiffness, and heat resistance, which 101 aluminum sheets do not possess. Instead, aerospace tooling typically uses materials like high-strength aluminum alloys (such as 7075 or 2024) or even specialized materials like titanium alloys for more demanding applications. These materials offer superior mechanical properties and can withstand the demanding conditions in aerospace manufacturing.

Send your message to us

Aluminum Sheets Utah - 1050 1060 1100 3003 5052 5 Bar Aluminum Tread Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords