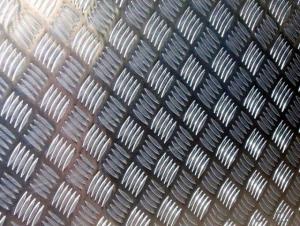

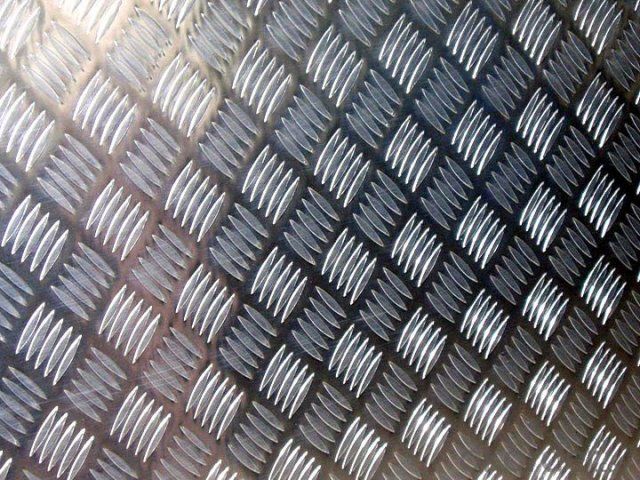

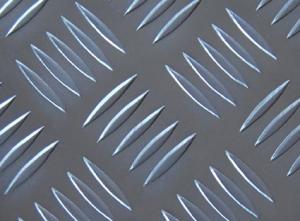

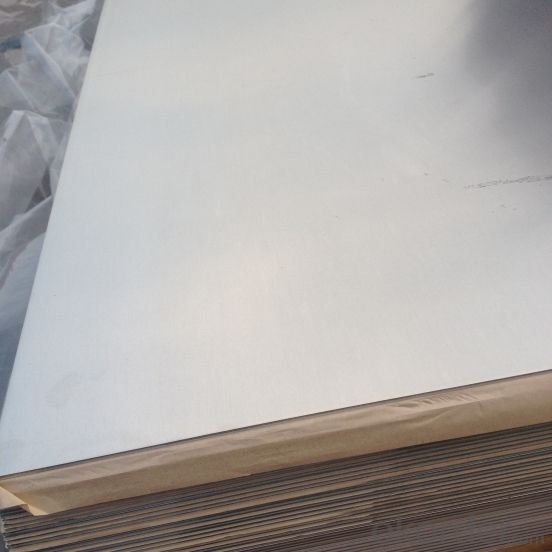

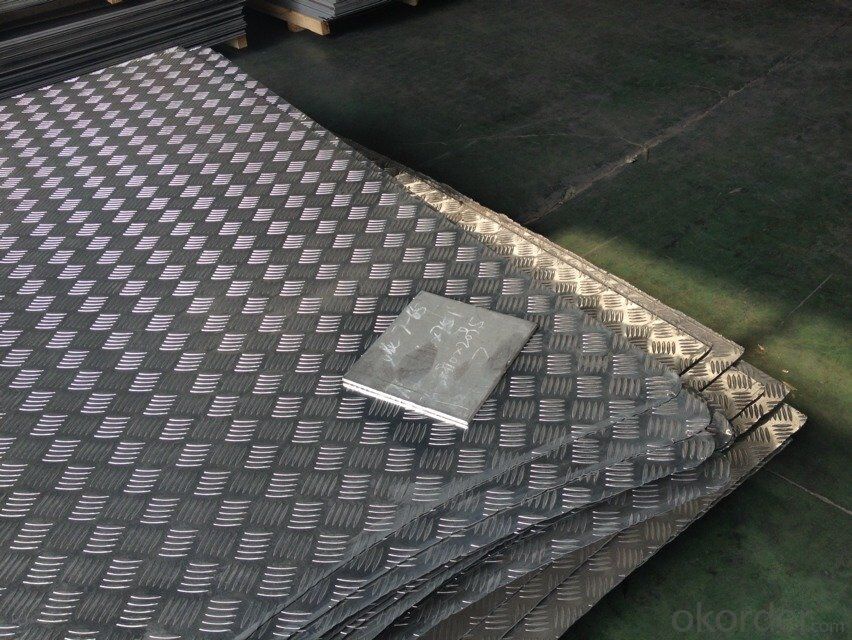

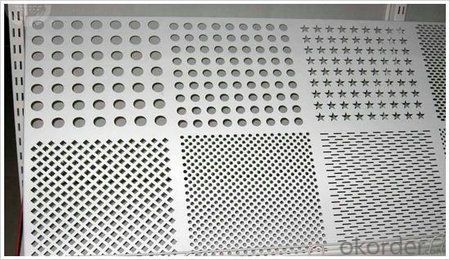

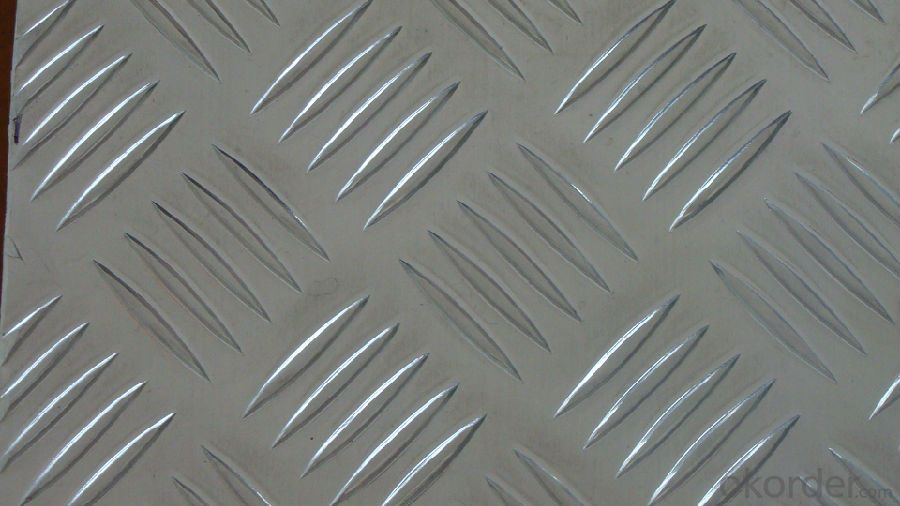

Aluminum Sheets for Sale Camden County - 3003 3004 5052 5754 Five Bar Diamond Aluminium Tread Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

aluminum chequered plate are widely usd for bus, cars and shipping vessel as the floor....

Aluminum tread plate is also called anti-slide aluminum sheet which is widely used in manufacturing vehicles, ships, washing machines, refrigerator shell, etc.

Specification:

Alloy: 1050, 1060, 1100, 3003, 3105, 5052

Temper: O, H12, H14, H16, H18, H22, H24, H26, H32

Thickness: 1.0~10mm

Width: 1000~1600mm

Length: 1000~6000mm

Packing:

One roll in an individual box or printed PP bag

Certain quantities in a standard carton

Depends on customer’s request

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

- Q: Is it possible to use aluminum sheets in the manufacturing process of solar panels?

- <p>While aluminum sheets can be used in the construction of solar panels, they are not the primary material for making the solar cells themselves. Aluminum is typically used for the frame or backsheet to provide structural support and protection. The actual solar cells are made from materials like silicon, which is capable of converting sunlight into electricity. So, while aluminum plays a role in the assembly of solar panels, it is not used to create the photovoltaic cells that generate power.</p>

- Q: Are 101 aluminum sheets suitable for marine environments?

- No, 101 aluminum sheets are not suitable for marine environments as they lack sufficient corrosion resistance.

- Q: Can aluminum sheets be used for boat hulls?

- Aluminum sheets are indeed suitable for boat hulls. The lightweight property, high strength-to-weight ratio, and exceptional corrosion resistance of aluminum make it a popular choice for constructing boat hulls. Boat builders often utilize aluminum sheets to craft durable and robust hulls that can withstand the challenges of harsh marine environments. The versatility of aluminum enables the application of various fabrication techniques, making it suitable for a wide range of boat types, such as recreational, fishing, and commercial vessels. Additionally, aluminum hulls necessitate less maintenance compared to alternative materials, offering boat owners a cost-effective solution.

- Q: How do aluminum plates drill?

- There are many drilling equipment for aluminium sheets,First, the engraving machine can be big or small, and can shape strange.Can also be a self tapping screw drill, which can drill.

- Q: How do you cut aluminum sheets?

- Aluminum sheets can be cut using various methods such as shearing, sawing, laser cutting, or using water jet cutters. The most suitable method depends on the thickness and size of the aluminum sheet as well as the desired precision and efficiency.

- Q: Can aluminum sheets be used for sound insulation?

- Yes, aluminum sheets can be used for sound insulation to some extent. While aluminum is not the best material for soundproofing compared to others like rubber or foam, it can still provide some level of sound insulation when used correctly. Aluminum sheets can be installed as a barrier or partition in walls, ceilings, floors, or other surfaces to reduce the transmission of sound waves. However, it is important to note that additional soundproofing materials or techniques might be necessary to achieve optimal results.

- Q: why does the hardness of 2024 aluminum sheet not increase but decrease after thermal treatment?

- The hardness of 2024 aluminum sheet will decrease after thermal treatment(solution treatment), and it will increase after aging treatment.

- Q: What does 3003-O aluminum mean?

- 3003 is a kind of AL-SI alloy of Al Mn alloyThere are four basic states of aluminum alloys:F--Free the condition of a product after a normal working procedure requires no special heat treatment or hardening, and the mechanical properties are not limited.H-- strain hardening statusO-- annealed state (the softest of all States)T-- heat treatment status

- Q: Can aluminum sheets be used for soundproofing?

- Indeed, soundproofing can be achieved using aluminum sheets. With its high density, aluminum serves as a formidable obstacle to the transmission of sound. By combining aluminum sheets with sound-absorbing materials like foam or fiberglass, the propagation of sound waves can be decreased, thereby mitigating noise pollution. Moreover, the versatility of aluminum sheets allows for effortless installation on walls, ceilings, and various surfaces, making it an ideal choice for soundproofing purposes.

- Q: Can aluminum sheet be used for automotive heat shields?

- Yes, aluminum sheet can be used for automotive heat shields. Aluminum is a popular choice for heat shields in the automotive industry due to its excellent thermal conductivity and high heat resistance. It helps to protect sensitive components from excessive heat by reflecting and dissipating the heat away from the desired areas. Additionally, aluminum is lightweight and corrosion-resistant, making it an ideal material for automotive applications. It is commonly used in various heat shield designs, including exhaust heat shields, engine heat shields, and under-carriage heat shields.

Send your message to us

Aluminum Sheets for Sale Camden County - 3003 3004 5052 5754 Five Bar Diamond Aluminium Tread Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords