2x4 Fiberglass Ceiling Tiles - 100 Density Black Fiber Glass Wool Acoustic Ceiling

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

100 density Black Fiber Glass wool acoustic ceiling

Specifications:

Main Material: Fiberglass wool

Density: Standard 100kgs/m3

Thickness: 15mm,20mm, 25mm and etc.

Size: 600*600mm,600*1200mm and etc.

Textures: White painted, Mix Acoustic, White Spray, BlackSpray

Edge: Square, Tegular for 15/24 grids, Concealed

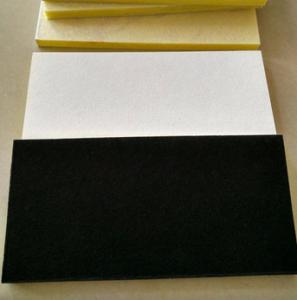

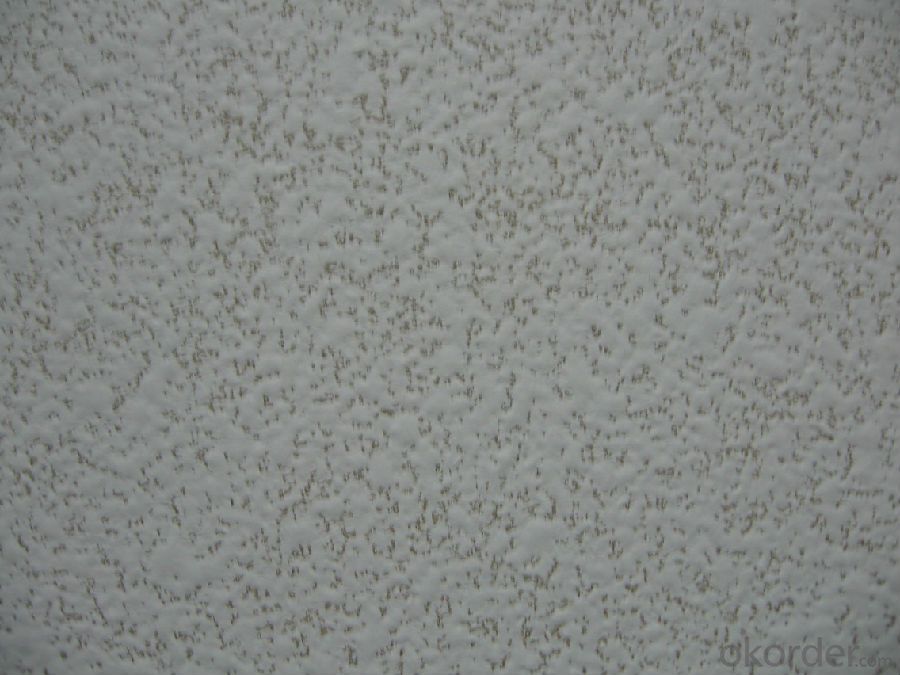

Black spray White spray

Mix Acoustic White painted

Fiberglass acoustic ceiling tiles decoration material

Quick Detail:

Non-combustible;

No sagging, warpping or delaminating;

Green building material;

Excellent sound absorption;

With different pattern available;

Applications:

Halls, Classrooms, Offices, Shopping centers, etc.

Competitive Advantages:

Fire-resistant;

Thermal-insulation;

Humidity-resistant;

Cleanability;

Environmental;

Elegant;

Safety and Convenience;

- Q: How the old house wall moldy

- The old house wall moldy if directly scraping the white, then get well, not how long it will moldy hair. Because there is the presence of mold spores, and there is a suitable breeding environment for mold, coupled with the appropriate temperature and humidity, not long time there will be the phenomenon of moldy hairy hair. If you want to avoid another wall moldy, first of all to find out the cause of the wall moldy long hair, and then targeted to control, will be a long time to avoid moldy. Cause the wall moldy long hair in the north is generally the wall insulation is not good lead to winter wall cold condensation, in the south is generally leaking and weather humid air humidity for a long time too long, so the north must first do Wall insulation layer, the south to do a good job waterproofing and trying to reduce the indoor air humidity. On this basis, would like to scratch the white words, the first to eradicate the old moldy wall, and then spray on the grass at the wall "will be bright wall grams of mold king" two to three times, completely kill the wall mold spores (to the original There are moldy long hair parts around the expansion of 10-20 cm), to be dry after the wall, and then the normal treatment of the wall, and finally painted on the surface will be bright wall grams of mold Wang B liquid, you can prevent a long time The walls are moldy.

- Q: I wonder if there is fibreglass in it.It is easily scraped off, but creates dust from particles.I could remove it myself, but am wary of the dangers it might pose to lungs.There are no windows to the classroom. A student told me that it exacerbates his asthma.The schoolboard solution is to cover it up with a hanging tiledceiling.Is that reasonable?No money in education for removal, unless dangerous. Do I have any reason for concern?

- If it is indeed dangerous, then it would have to be professionally removed. YOU would have to have the STATE come in and test the material. Renovation and Repair Contents Techniques for Protecting Occupants from Renovation Pollutants References and Resources Renovation is one of the major causes of poor indoor air quality (IAQ) in schools, and is often conducted while the building is occupied.

- Q: i removed what i think are fiberglass ceiling tiles cause they had yellow long hairs on them. but i am worried that they might of been asbestos because my lungs feel bad. people tell me to not worry because it was only this one time and only people exposed all the time at there jobs need to worry, but i am still worried.

- pop round to doctors and get best advise. it is unlikely to be asbestos form sound of it and more likely fibreglass. this is a known irritant and you should have been wearing eye and breathing and gloves protection etc.

- Q: What is good material for external wall insulation

- Foam cement insulation materials Foam cement, the earliest German material used in China was introduced around 1980. Through the foaming system of the foaming machine, the foaming agent is fully mechanically foamed and the foam is mixed with the cement slurry and then subjected to in-situ construction or mold forming through a foaming machine pumping system, The formation of a large number of closed pores containing a new type of lightweight thermal insulation materials. It is a bubble-like insulation material, highlighting the characteristics of the concrete is formed inside the closed foam hole, so that lightweight concrete and insulation insulation.

- Q: Our basement bedroom does not have insulation in ceiling between joists but it is possible to insulate from another area that is not finished but I would have to use the insulation which is blown in between the joists. Is this a good insulation and is it practical to do for noise reduction? Otherwise, we would have to tear out the ceiling in the bedroom and use the fiberglass insulation. Do you have any other ideas or suggestions for noise reduction? This is a new home.

- Noise reduction would be the greatest benefit, because the ceiling is not exposed to lower temperatures. If the joists are unobstructed by solid braces, there are insulators who bore a hole in each end between joists and pump in a foam type insulation. I have seen this done to outside walls on a house before putting on siding.

- Q: Epoxy resin when the ratio of curing agent than the high proportion of what impact? What is the impact of low. What is the reason for hardening after curing?

- When the proportion of curing agent is 30% higher than normal, the cured glue feels soft.

- Q: I had the roof replaced last summer, but havent had the energy to get up there and take down the ceiling tiles and the fiberglass insulation. I started removing it a section at a time a week ago, and wow! What a mess!. Gravel is falling down on my head and the insulation and tiles are dry now, but its still hard to pull them out. Should I be wearing a mask? Is there anything in the old dried out insulation and ceiling tiles that I should cover my nose? Its making a really big mess, so any suggestions will be helpful.

- A mask would be good. No telling what old insulation is made of. Get some large heavy plastic sheets. Place in rooms where your are taking down tile. Will help a lot on the cleanup. Makes real big trashbags. You may have to dump before it gets too heavy.

- Q: How to choose how to buy closet door ah?

- When choosing a wardrobe, note the following: 1. Is the thickness of the door panel full of thick, high enough height. Sliding door with the wood, the best choice 10mm or 12mm thick plate, use up strong, stable, durable; slightly worse will use 8mm thick, it is relatively thin, frivolous. Door height is decided whether the decoration to the ceiling, requiring a single plate height of 2.8 meters or more, up to the ceiling. 2. Whether the variety of doors and materials are rich and varied. Different consumer ideas correspond to different color hobbies. Currently on the market for the production of sliding doors of the main materials are wood, glass, mirrors and other special materials. Colors are beech, cherry, maple, maple, oak, black walnut, white pine and so on. 3. Whether the door and the border are consistent. Brand wardrobe cabinet door frame, door from the same manufacturers, the color lines can be achieved consistent, supporting unity. And miscellaneous wardrobe is often patchwork, can only find similar color plate, border, can not be completely consistent. 4. Whether the wheels are smooth, pressure, wear, safe and reliable. Brand wardrobe pulley is generally made of carbon glass fiber (international new high-tech materials) made with within the ball, with a non-drying lubricant, it can easily push and pull, smooth and flexible, and bearing capacity, pressure, wear Not deformed. Pulley guide is the sliding door of the core technical parts, we must carefully choose. 5. Whether the cabinet is professional, whether the design is scientific fashion. Currently popular fashion wardrobe cabinet, the design is very scientific and reasonable

- Q: How to conduct a comprehensive review of self-leveling

- Self-leveling construction should pay attention to the three elements: ① humidity: ground moisture content should be less than 3% (self-leveling manufacturers require to keep the soil surface dry). Use CCM moisture tester. ② surface hardness: with a sharp chisel fast cross cut the surface, the intersection should not be burst. Use a hardness characterizer. ③ surface flatness: with 2 m ruler test, the gap should not be greater than 2mm. Use the flatness tester.

- Q: What is the candle effect?

- For the natural phenomenon, there is a relatively reasonable explanation, known as the candle effect. Scientists believe that we can put a person wearing clothes, conceived as a candle inside and outside, clothes are candle, body fat is wax. Even a small flames may penetrate the skin, ignite the fat, and then slowly and continuously burn. ????Candle effect proved that the body itself has a burning source, as long as the environmental conditions meet, the human body can self-destruction. Is considered a case of spontaneous combustion in the body there is a frequent clue: smoking. Scientists believe that smoking may accidentally ignite what, most likely the bed of things; then, by the carbon monoxide choking faint, then, the fire into the skin, lit fat, people into a slow burning candles. The clothes and sheets are like candles, and the fat is wax. The heat of the fire is not high enough, so no other items in the room are burned. ????The truth is that no one has ever witnessed a person or an animal to burn himself and to ashes. Worse still: in the case of suspected spontaneous combustion of the human body, the victims are mostly elderly, weak people, often overweight, smoking and other issues, and are living alone.

Send your message to us

2x4 Fiberglass Ceiling Tiles - 100 Density Black Fiber Glass Wool Acoustic Ceiling

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords