Irradiation Cross-linkable Flame Retardant Polyolefin Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High temperature resistive, irradiation cross-linkable, flame retardant POE compound

1. Type and application

Type | Product | Application and Cable Specification |

FJZ1125H | 125℃Irradiation cross-linkable, flame retardant POE compound | Used for cross-linked wires of apparatus and instruments, electric motor and etc. Pass UL3271 standard. Meeting RoHs standard |

FJZ2125H | 125℃Irradiation cross-linkable, flame retardant POE compound | Used for cross-linked wires of apparatus and instruments, lamps and lanterns and etc. Meeting RoHs standard |

FJZ1135H | 135℃Irradiation cross-linkable, flame retardant POE compound | Used for cross-linked and insulating wires and cables of apparatus and instruments, equipments and etc. Meeting RoHs standard |

FJZ1150H | 150℃Irradiation cross-linkable, flame retardant POE compound | Same above, and pass the 38 grade standard of UL1581. Meeting RoHs standard |

2. Product description

Irradiation cross-linkable POE compound, based on POE resin, is produced and pelletized by special technology with adding special stabilizing agent, modifier, flame retardant, cross-linking agent and other special additives.

3. Processing

The compound can be processed with conventional extruders, and the screw with a minimum 20:1 L/D and low compression ratio die is recommended. Low tensile ratio is needed.

following temperature(℃) profile of extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

temperature ℃ | 140 | 145 | 150 | 155 | 150 | 150 |

4. Storage and transport

Packaging:25kg/bag, PE membrane inside bag and Kraft outside bag.

Storage and transport: Avoiding in direct sunlight and weathering. The storage place should be in clean, cool, dry, and ventilated conditions.

5. irradiated dosage

The normal irradiated dosage(recommended) of irradiation cross-linked and flame retardant POE compound is 15 megarad.

6. Properties

Table

Item | Unit | FJZ1125H | FJZ2125H | FJZ1135H | FJZ1150H | ||||

Standard | Typical | Standard | Typical | Standard | Typical | Standard | Typical | ||

Density | g/cm3 | -- | 1.34 | -- | 1.30 | -- | 1.33 | -- | 1.32 |

Hardness | ShoreA | -- | 91 | -- | 95 | -- | 92 | -- | 92 |

Tensile Strength | ≥ MPa | 12.5 | 14.0 | 12.5 | 16.0 | 12.5 | 15.0 | 13.8 | 16.0 |

Elongation at Break | ≥ % | 200 | 350 | 200 | 360 | 200 | 380 | 300 | 400 |

Impact Brittleness Temperature | ≤ ℃ | -25 | Pass | -25 | Pass | -25 | Pass | -25 | Pass |

Volume Resistivity, at 20℃ | ≥Ω﹒m | 1.0×1012 | 2.0×1013 | 1.0×1012 | 3.0×1013 | 1.0×1012 | 2.0×1013 | 1.0×1012 | 3.0×1013 |

Dielectric Strength | ≥MV/m | 20 | 24 | 20 | 25 | 25 | 25 | 25 | 25 |

Oxygen Index | ≥ | 30 | 30 | 27 | 28 | 27 | 27 | 27 | 27 |

Thermal Prolongation |

|

|

|

|

|

|

|

|

|

Elongation Under Load | ≤ % | 100 | 20 | 100 | 25 | 100 | 25 | 100 | 25 |

Permanent Elongation after cooling | ≤ % | 10 | 0 | 10 | 5 | 10 | 5 | 10 | 0 |

Thermal Aging |

|

|

|

|

|

|

|

|

|

Aging Temperature | ℃ | 158±2 | 158±2 | 158±2 | 158±2 | 165±2 | 165±2 | 180±2 | 180±2 |

Aging Time | h | 168 | 168 | 168 | 168 | 168 | 168 | 168 | 168 |

Variation on Tensile Strength | ≥ % | 80 | 103 | 80 | 102 | 80 | 107 | 80 | 110 |

Variation on Elongation at Break | ≥ % | 80 | 98 | 80 | 97 | 80 | 90 | 80 | 86 |

The above data are all the properties of compound after cross-linked.

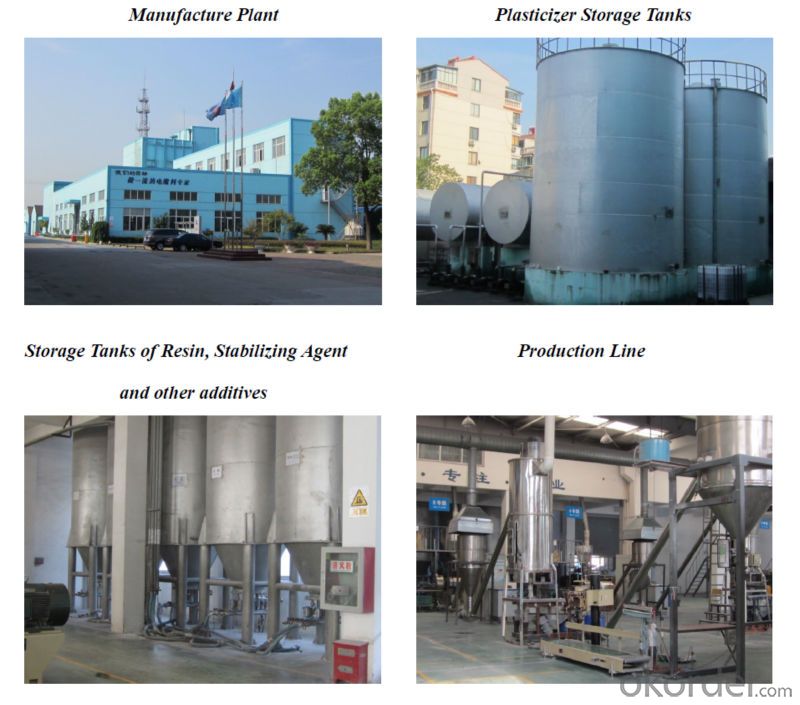

7. Company

- Q: What material is the disc made of, metal or plastic?

- The CD disk has a substrate thickness of 1.2mm, a diameter of 120mm, a hole in the middle, and a circular shape. It is the shape of the disc. The reason why the disk can be taken at will depends mainly on the hardness of the substrate.

- Q: What is the material of plastic dip?

- Also known as alias dip coated, hot dip coating, hot compress. Dip (plastic) is a kind of plastic coating process. According to the different raw materials used in dipping, they can be divided into liquid dipping (coating) and powder dipping (coating).

- Q: What are the plastic bags made of?

- General civilian products, mostly polyethylene (PE) to do, PE is divided into low pressure high-density HDPE, low pressure high-density LDPE and linear low-density LLDPE

- Q: What is the ash content of PP plastic raw materials?

- Pure PP leaves no ash and can be completely burned

- Q: What are the plastic raw materials?

- This polymer is made up of many smaller and simpler molecules made of covalent bonds. There are many kinds of polymers, one is to change the Prajna heat to classification, it can be divided into two categories.

- Q: Plastic raw materials are granular, why not powder?

- Who says plastic raw materials are granular?.

- Q: Characteristics and uses of CA plastics

- Cellulose acetate (Cellulose Acetate, hereinafter referred to as CA, or cellulose acetate, cellulose acetate) was first prepared in 1865 and is the acetate of cellulose. CA used for photographic film base, is a component of some adhesive for synthetic fiber.

- Q: How many kinds of plastic raw materials are there? How to distinguish them?

- According to the nature of the plastic after heating, it is divided into thermoplastic and thermosetting plasticsThermoplastic molecular structures are linear structure, softening or melting when heated, plastic into certain shape, after cooling and hardening. When heated to a certain extent to soften after cooling and harden, this process can be repeated several times. Such as polyvinyl chloride, polyethylene, polystyrene and other thermoplastic. Plastic molding process is relatively simple, can continuous production, and has very high mechanical strength, so it is developing very quickly.The molecular structure of thermosetting plastics is the body structure, softening also occurs in heated, can plastic into a certain shape, but is heated to a certain extent or amount of curing agent, hardened stereotypes, re heating become soft and will not change shape. The thermosetting plastic processing molding after heating no softening, and therefore can not be recovered then, such as phenolic, amino plastics, resin and other plastic. These are thermosetting plastic molding process is more complex, so the continuous production is difficult, but its good heat resistance, not easy to deformation, and the price is relatively low.

- Q: What two ingredients fit together to solidify like plastic?

- If the viscosity of the epoxy resin is reduced, a curing agent with poor adhesion (e.g., I am a fast curing agent) is adopted. By vacuum and so on, let the glue into the gap, pay attention to the hardness of the curing agent should be higher, so as to effectively measure

- Q: What are the criteria for the classification of plastic materials at injection molding and extrusion?

- In comparison, the lower melt flow rate is applicable to the extrusion grade, and the higher is applicable to the injection molding grade. As to what is low and what is high, there is a difference between the different plastic varieties.

Send your message to us

Irradiation Cross-linkable Flame Retardant Polyolefin Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords