Geomembrana Precio para Estanque de Pesca, Laguna, Presa y Embalse de HDPE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of HDPE Geomembrane for Fish Farm Pond Lake:

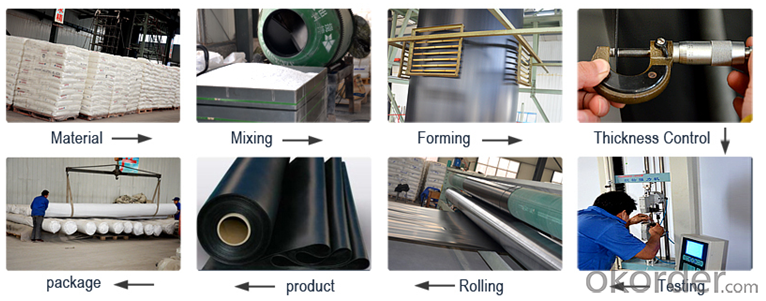

HDPE waterproofing membranes use finest HDPE resin as raw material, they were made of inflation method and advanced automatic equipments, all the products are produced and inspected according to and complied with ASTM standard, CJ/T234 2006, GB/T17643 1998, etc.

They are complete in specifications: double smooth surface, double rough surface and single rough surface. The widest broad width can reach 8M, the thickness if 0.1 to 3.0mm.

Main Features of HDPE Geomembrane for Fish Farm Pond Lake:

1,Environmental protection and sanitation

(landfill, ash dam for power plant,Wastewater sewage treatment plant,storage of dangerous goods , industrial waste,construction and demolition waste,toxic and harmful chemicals disposal sites,.ect.)

2,Used in seawater or freshwater breed field

3,Pond liner,canal linings,tank linings,raw water treatment reservoirs,retention poinds

4,Municipal projects

(Subway, tunnel and underground storeroom,underground subway, engineering underground and

reservoirs on the roof, and the park on the roof, the lining in the sewage pipes, ect.)

5,Mining

(washing and pool heap leaching, the ash-field, dissolved, precipitation,

the yard, the tailings seepage substrates, etc.) .

6,Garden

(artificial lakes, ponds, the lining of tank in golf course, slope protection, ect.)

7,Petrochemical

(chemical plants, oil refineries, oil tank of fill stations , chemical reactions pound, the lining of settling basin, second lining, ect.)

Specifications of HDPE Geomembrane for Fish Farm Pond Lake:

Properties | 0.75mm | 1.00mm | 1.50mm | 2.00mm | 2.50mm | 3.00mm |

Thickness-mil(min.ave) Lowest individual of 10 values | Nom.(mil)-10% | Nom.(mil)-10% | Nom.(mil)-10% | Nom.(mil)-10% | Nom.(mil)-10% | Nom.(mil)-10% |

Density(min.) | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 |

Yield strength | 11KN/m | 15KN/m | 22KN/m | 29KN/m | 37KN/m | 44KN/m |

Breaks strength | 20KN/m | 27KN/m | 40KN/m | 53KN/m | 67KN/m | 80KN/m |

Yield elongation | 12% | 12% | 12% | 12% | 12% | 12% |

Break elongation | 700% | 700% | 700% | 700% | 700% | 700% |

Tear resistance | 93N | 125N | 187N | 249N | 311N | 374N |

Puncture resistance | 240N | 320N | 480N | 640N | 800N | 960N |

Stress crack resistance | 300hr | 300hr | 300hr | 300hr | 300hr | 300hr |

Carbon black content | 2.0-3.0% | 2.0-3.% | 2.0-3.% | 2.0-3.% | 2.0-3.% | 2.0-3.% |

Carbon Black Dispersion | Note(4) | Note(4) | Note(4) | Note(4) | Note(4) | Note(4) |

Standard OIT | 100 min | 100min | 100 min | 100min | 100min | 100min |

High Pressure OIT | 400min | 400min | 400min | 400min | 400min | 400min |

Standard OIT(min.ave.)- % retained after 90 days or(85ºC) | 55% | 55% | 55% | 55% | 55% | 55% |

High Pressure OIT(min.ave.)- %retained after 90 days (85ºC) | 80% | 80% | 80% | 80% | 80% | 80% |

UV Resistance( High Pressure OIT (min.ave.)-%retained after 1600hrs) | 50% | 50% | 50% | 50% | 50% | 50% |

-70℃ The Low Temperature Embrittlement Performance mpact | Pass | |||||

Water Vapor Penetration Coefficient g.cm (cm2.s.Pa) | ≤1.0X10-13 | |||||

Dimensional Stability | ±2 | |||||

Applications of HDPE Geomembrane for Fish Farm Pond Lake:

1.Prevent leakage disposal in waste burying field or waste water or waste dregs disposing field,river bank,lake dam ,mine remainings ,reservior,tunnel,liquid storage ,pool(pit,mine)

2.Preventing leakage in subway ,basement,tunnel ,hole

3.Anti-solt leakage in roadbed and other groundtill

4.The plane direction laying of dam ,the vertical direction laying fou groundtill ,used in the construction fence and waste material field

5.Used in seawater or freshwater feed field

6.Used in groundtill of road,highway ,railway and waterproof layer of swelling clay and wet collapsed loess

Preventing leakage on rooftop.

IMages of ResistaHDPE Geomembrane for Fish Farm Pond Lake:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: What is the operating principle of the vacuum laminating machine?

- The laminating machine must be the plastic packaging machine. The working principle is to insert the materal (or paper) to be plastic coated into the special plastic package, put the material into the plastic packaging machine, melt and solidfy the adhesive of the plastic package by heating and pressing and exhaust the air at the same time. By then plastic packaging is completed.

- Q: Are geomembranes suitable for use in mining heap leach pads?

- Yes, geomembranes are suitable for use in mining heap leach pads. They provide an effective barrier to prevent the loss of valuable leach solutions and minimize environmental impacts by preventing the contamination of groundwater. Geomembranes are highly resistant to chemical and physical degradation, making them an ideal choice for lining heap leach pads in mining operations.

- Q: What's the technical standards of geomembrane?

- The national standards of geomembrane is GB / T17642-2008. Geomembrane 1. longitudinal and transverse breaking strength. 2. Vertical and horizontal elongation corresponding to the standard strength. 3. CBR bursting strength 4. 5 vertical and horizontal tearing strength. 5, hydrostatic pressure resistance. 6. peel strength. 7. vertical penetration index. 8, width deviation, the above technical requirements that confirm to the national standard are national standard geomembrane.

- Q: How do geomembranes protect against soil erosion in erosion control projects?

- Geomembranes are impermeable liners that are used in erosion control projects to prevent soil erosion. These liners act as a barrier, preventing water from infiltrating into the soil and carrying away the sediment. By effectively containing water and providing a stable surface, geomembranes protect the underlying soil from erosion caused by rainfall, runoff, or other erosive forces.

- Q: Can geomembranes be used for oil and gas containment?

- Yes, geomembranes can be used for oil and gas containment. These synthetic liners are designed to provide a barrier against leaks, spills, and seepage, making them an effective solution for preventing the escape of oil and gas from storage tanks, pipelines, or containment systems. Geomembranes offer excellent chemical resistance and durability, making them a reliable choice for the containment of hazardous substances such as oil and gas.

- Q: What is the working principle of the electric heating film

- The electric heating film Electric heater belongs to is a new generation electric heater, which uses full transparent high temperature electric heating film as the heating material. The hot air passage structure is adopted to enhance the heat transfer mode, and the heat starting will be faster, and the temperature of the air outlet is more than 100 in 3 minutes, but it will imeediately cool off.

- Q: Is there the parameters of three-dimensional geotechnical drainage board?

- The plastic?drainage?plate, also known as the plastic drain with several shapes of wavy type, Harmonica type, and so on. The middle is an extruded plastic core, skeleton and channel drainage belt, which is parallel cross section was discharged on both sides in a non-woven geotextile fabric wrap for the filter layer, the core band play a supportive role and the filter layer of water seeping up , silt, silt soil quality, and other saturated hydraulic fill filling viscous and miscellaneous drainage consolidation method using soft foundation treatment good vertical channels, greatly reducing the soft soil consolidation time.

- Q: Can geomembranes be used for decorative purposes?

- No, geomembranes are primarily used for containment and environmental protection purposes rather than for decorative purposes.

- Q: How many kinds of the mobile phone film?

- More people use the HD film. The frosted membrane can anti fingerprint, but the image is not very clear. The diamond film has many small spots, and can anti-scratch and very beautiful. The tempered film can prevent scratch and falling, the cell phone wrapped membrane can protect the back of the phone, the color film can beautify the body of phone.

Send your message to us

Geomembrana Precio para Estanque de Pesca, Laguna, Presa y Embalse de HDPE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords